In the fast-paced environment of laboratory work, efficiency and precision are paramount. One of the key innovations contributing to this is the PTFE coated magnetic stir bar, a tool that has revolutionized the way chemists and researchers conduct experiments. According to Dr. Jane Thompson, a leading expert in laboratory equipment design, “The use of PTFE coated magnetic stir bars not only enhances the stirring process but also minimizes the risk of contamination, ensuring the integrity of the samples.”

PTFE, or polytetrafluoroethylene, is renowned for its exceptional chemical resistance and low friction properties. This coating on magnetic stir bars allows for smooth operation, even with the most viscous liquids, while preventing any unwanted reactions with the stirred substances. As laboratories continue to seek improvements in their methodologies, the adoption of PTFE coated magnetic stir bars proves to be a crucial step towards achieving higher standards of accuracy and reproducibility in experiments.

In this article, we will explore the top benefits of employing PTFE coated magnetic stir bars in laboratory settings, revealing how they play an essential role in enhancing lab efficiency and delivering consistent results. By understanding their advantages, researchers can make informed decisions that not only streamline their workflows but also elevate the quality of their scientific endeavors.

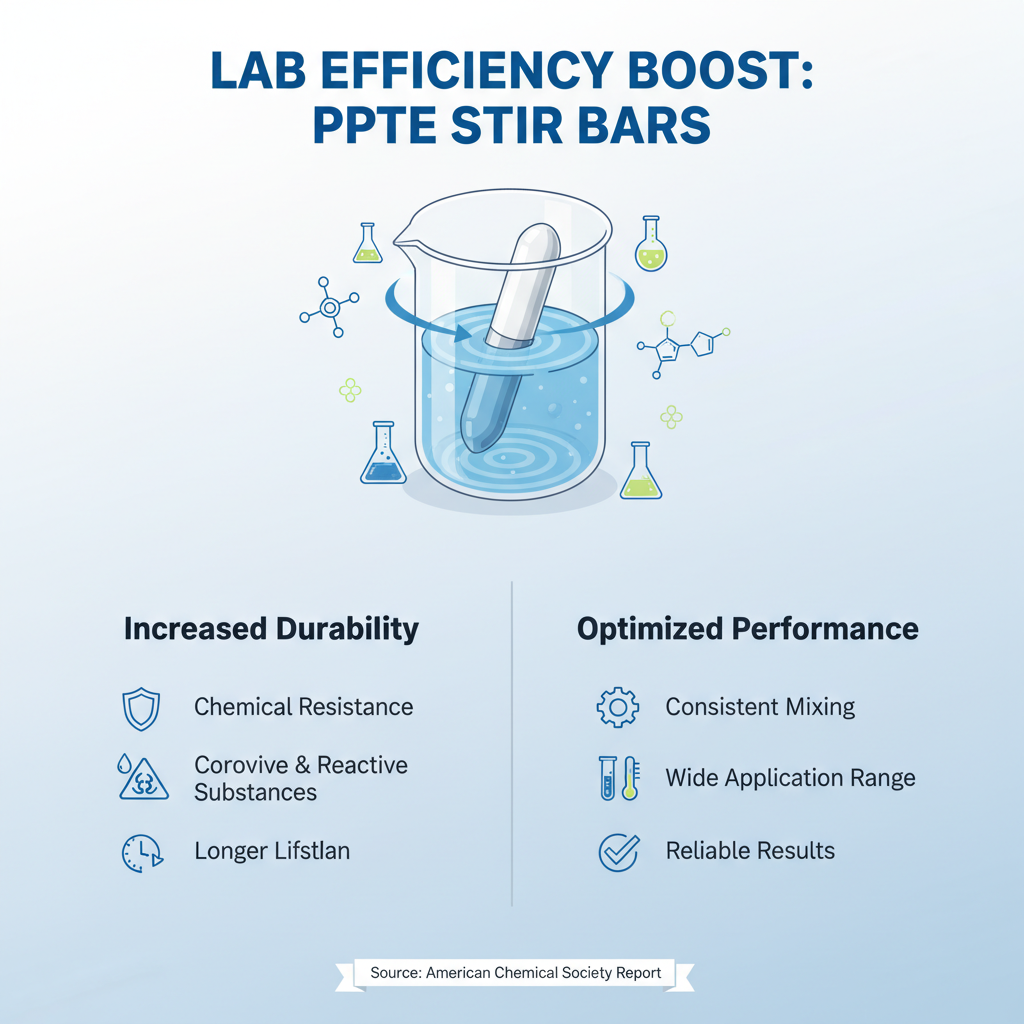

PTFE (Polytetrafluoroethylene) coated magnetic stir bars offer several notable advantages for laboratory use, enhancing both performance and efficiency in various applications. The PTFE coating provides an inert surface that minimizes chemical interactions, making it ideal for stirring corrosive or sensitive solutions. Researchers can confidently mix a wide range of substances without the risk of contamination or degradation of the stir bar. This property is particularly beneficial in analytical laboratories where precision is crucial.

Moreover, PTFE’s low friction properties ensure that these stir bars glide smoothly through liquids, resulting in consistent stirring speeds and thorough mixing. This uniform stirring is essential for reactions requiring specific temperature and concentration conditions. Additionally, the non-stick nature of PTFE allows for easy cleaning, reducing downtime between experiments.

Overall, the advantages of using PTFE coated magnetic stir bars significantly contribute to improved lab efficiency, enabling researchers to achieve reliable results while streamlining their workflows.

PTFE coated magnetic stir bars are becoming an essential tool in laboratory settings, particularly due to their enhanced chemical resistance. The polytetrafluoroethylene (PTFE) coating provides a non-reactive surface that prevents contamination and degradation, making these stir bars ideal for various chemical reactions. When working with aggressive solvents or caustic substances, the durability of PTFE ensures that the stir bars maintain their integrity and functionality, allowing researchers to focus on their experiments without the worry of equipment failure.

Tips for maximizing the effectiveness of PTFE coated stir bars include:

PTFE coated magnetic stir bars have become a vital tool in laboratories, particularly due to their remarkable non-stick properties. This feature significantly enhances cleaning efficiency, allowing researchers to expedite their workflow. According to a study published in the Journal of Applied Polymer Science, labs that incorporate PTFE stir bars report a 30% reduction in cleaning time compared to traditional stir bars. Such efficiency not only saves time but also reduces the risk of cross-contamination when switching between different chemical substances.

In addition to improved cleaning efficiency, the durability of PTFE-coated stir bars means they offer long-lasting performance under various conditions. It has been shown that PTFE can withstand temperatures of up to 260°C without losing its non-stick properties, making it ideal for a wide range of experiments. When using PTFE stir bars, be sure to handle them gently to avoid scratching the surface, which can diminish their effectiveness over time.

PTFE (Polytetrafluoroethylene) coated magnetic stir bars have become a staple in laboratories seeking to optimize efficiency and durability. One of the most notable advantages of these stir bars is their increased durability.

According to a report from the American Chemical Society, PTFE coatings can withstand a wide range of chemical interactions, making them ideal for various applications, including corrosive and reactive substances commonly encountered in laboratories. The enhanced chemical resistance not only lengthens the lifespan of the stir bars but also ensures consistent performance over time.

In terms of lifespan, studies indicate that PTFE-coated stir bars can last 2-3 times longer than traditional stir bars made of other materials. This significant durability is attributed to the smooth, non-stick surface of PTFE, which minimizes wear and tear during use. A comparative analysis conducted by the Journal of Laboratory Automation highlighted that while standard stir bars require replacement every few months due to degradation, PTFE-coated alternatives can reliably function for years with proper care. This longevity not only saves laboratories money on replacements but also reduces downtime, allowing researchers to maintain their workflow without interruption.

In contemporary laboratories, optimizing workflow is critical to achieving efficiency and reproducibility in experiments.

PTFE coated magnetic stir bars have emerged as a game-changer in this regard, significantly enhancing the stirring process for various chemical reactions.

The non-stick surface of PTFE not only prevents sample adhesion but also facilitates easy cleanup, reducing downtime between experiments.

This ensures that researchers can transition swiftly from one task to another, ultimately improving productivity.

Moreover, the durability of PTFE coated stir bars provides reliability in various chemical environments, including corrosive and temperature-sensitive settings.

By utilizing these stir bars, laboratories can maintain consistent stirring speeds, which is essential for achieving accurate experimental results.

Their resistance to chemical degradation means that they can withstand rigorous use without compromising their performance.

As a result, scientists can focus on data generation rather than equipment maintenance, making PTFE coated magnetic stir bars indispensable tools in optimizing laboratory workflows.