In the realm of laboratory mixing, efficiency and precision are paramount. As research and experimentation become increasingly complex, the need for reliable mixing tools has never been more critical. One such tool that has garnered attention for its superior performance is the PTFE stirrer bar. According to Dr. John H. Smith, a leading expert in materials science, "The use of PTFE stirrer bars not only enhances mixing efficiency but also significantly reduces contamination risk, paving the way for more accurate experimental results."

PTFE stirrer bars, distinguished by their unique chemical resistance and low friction properties, offer unparalleled advantages in various laboratory settings. Unlike traditional stirrer bars, which may react with specific chemicals, PTFE stirrer bars ensure that the integrity of the samples is maintained, thus delivering results that researchers can trust. This article explores the multifaceted benefits of PTFE stirrer bars, emphasizing their role in improving laboratory mixing efficiency.

By understanding the capabilities of PTFE stirrer bars, laboratory professionals can make informed decisions that elevate their experimental outcomes. Whether in a research facility or an academic setting, the integration of PTFE stirrer bars into daily practices promises to streamline operations and enhance scientific discoveries.

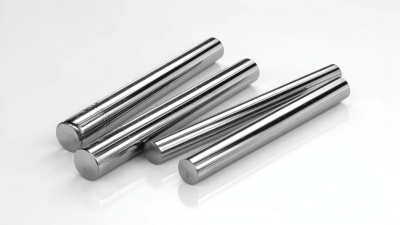

PTFE stirrer bars have become essential tools in modern laboratories, significantly enhancing mixing efficiency across various applications. These versatile stirrers, made from polytetrafluoroethylene, offer unique chemical resistance, making them ideal for mixing reactive or corrosive substances without the risk of contamination. Their non-stick surface ensures a smooth stirring experience, allowing for uniform mixing of samples without residue build-up, leading to improved experimental outcomes.

Tip: When selecting a PTFE stirrer bar, consider the size and shape based on your specific vessel and the volume of liquid. A shorter bar may work better for smaller volumes, while longer bars can provide improved mixing in larger containers.

In addition to their chemical stability, PTFE stirrer bars operate quietly and efficiently, reducing noise pollution in the laboratory environment. This essential feature allows researchers to maintain focus during prolonged experiments. Furthermore, the durability of PTFE ensures a longer lifespan for stirrer bars, proving to be a cost-effective choice in laboratory settings.

Tip: Regularly inspect your stirrer bars for wear and tear to maintain optimal mixing performance. Clean them properly after each use to prevent cross-contamination between experiments.

PTFE stirrer bars have become an essential tool in laboratories due to their remarkable chemical resistance and longevity. The unique properties of PTFE (polytetrafluoroethylene) allow these stirrer bars to withstand harsh chemical environments without deteriorating. Unlike traditional stirrer bars made from materials such as stainless steel or glass, PTFE does not react with aggressive solvents or acids. This characteristic not only enhances the safety of laboratory processes but also ensures that the stirrer bars maintain their integrity over time, making them a cost-effective choice for long-term use.

Moreover, the longevity of PTFE stirrer bars translates into reduced replacement frequency, thus minimizing laboratory downtime. Their inert nature means that analyses remain uncontaminated, preserving the accuracy of experimental results. Additionally, the smooth surface of PTFE stirrer bars facilitates easy cleaning, further contributing to their durability. As laboratories increasingly seek efficient and reliable mixing solutions, the beneficial properties of PTFE stirrer bars clearly position them as superior alternatives, markedly improving mixing efficiency and sustaining performance across a variety of chemical applications.

In a recent comparative analysis of stirrer bars, the advantages of

PTFE (Polytetrafluoroethylene) stirrer bars

over traditional materials become increasingly evident. PTFE’s chemical

resistance and non-stick properties significantly enhance laboratory mixing

efficiency, particularly when dealing with viscous or reactive substances.

Research indicates that PTFE stirrer bars can maintain homogeneous mixtures

better than their metal counterparts, leading to more reproducible results

in experimental settings. According to data from industry reports, laboratories

utilizing PTFE stirrer bars report up to a 30% increase

in mixing efficiency, which is crucial for precise and reliable experimental

outcomes.

When choosing stirrer bars, it’s essential to consider the specific application.

For example, while metal stirrer bars may be cost-effective for simple tasks,

they can lead to contamination and reactivity issues, particularly in sensitive

experiments. In cases such as gas sensing studies involving metal-organic

frameworks (MOFs), where material integrity is paramount, PTFE stirrer bars

offer a significant advantage. Laboratory professionals should also be aware

that PTFE bars are compatible with a wider range of solvents, ensuring

versatility across various research applications.

Tips:

In the realm of laboratory mixing, optimizing processes is crucial for achieving consistent results across various applications. PTFE stirrer bars have emerged as a pivotal tool in this pursuit, offering distinct advantages over traditional stirrers. Due to their non-stick properties and chemical resistance, PTFE stirrer bars facilitate efficient mixing, reducing the risk of contamination and enhancing the reproducibility of experiments. Additionally, their smooth surfaces minimize wear on mixing vessels, prolonging their lifespan and maintaining the integrity of sensitive solutions.

In diverse laboratory settings, the versatility of PTFE stirrer bars is notable. They perform exceptionally well in both aqueous and organic solvents, making them suitable for a wide range of chemical reactions and processes. Whether in pharmaceutical research, material science, or biochemistry, using PTFE stirrer bars can significantly enhance mixing efficiency. The ability to customize the size and shape of stirrer bars further allows researchers to tailor their equipment to specific experimental conditions, ensuring optimal performance and outcomes. This adaptability positions PTFE stirrer bars as a preferred choice for laboratory professionals seeking to refine their mixing processes.

PTFE stirrer bars have gained significant traction in laboratories due to their remarkable mixing efficiency and chemical resistance. A series of case studies reveal their efficacy in enhancing mixing outcomes across various experimental setups. For instance, in a biochemical research facility, researchers employed PTFE stirrer bars to achieve a homogeneous solution of diverse reagents. The results indicated not only improved solubility rates but also a reduction in the time required for thorough mixing, allowing scientists to expedite their experiments without compromising on quality.

Another case study in an environmental lab showcased the advantages of PTFE stirrer bars in complex matrix mixing. When analyzing soil samples with varying particulate sizes, traditional stirrer bars struggled to maintain uniformity. However, the implementation of PTFE stirrer bars allowed for a smoother and more consistent mixing process, leading to more reliable analytical results. The non-reactive nature of PTFE ensured that the stirrer bars did not introduce contamination, further enhancing the integrity of the data collected. These examples underscore the role of PTFE stirrer bars as a transformative tool in laboratory settings, facilitating superior mixing performance and better research outcomes.

| Application | PTFE Stirrer Bar Length (cm) | Average Mixing Time (minutes) | Viscosity of Medium (cP) | Mixing Efficiency (%) |

|---|---|---|---|---|

| Chemical Reaction | 5 | 15 | 200 | 90 |

| Biological Sample Preparation | 7 | 10 | 150 | 95 |

| Nanoparticle Suspension | 8 | 20 | 250 | 87 |

| Polymer Blending | 6 | 12 | 300 | 92 |

| Solvent Mixing | 4 | 8 | 100 | 88 |