In modern laboratories, precision and efficiency are paramount, making the choice of equipment critically important. Among the myriad tools available, PTFE magnetic stir bars have emerged as essential components in various applications, thanks to their unique chemical resistance and durability. According to a recent industry report from ResearchAndMarkets, the global laboratory equipment market is expected to reach $50 billion by 2025, driven by the demand for more efficient and reliable laboratory processes. PTFE magnetic stir bars are a significant contributor to this trend, offering enhanced stirring capabilities while minimizing contamination. With their ability to withstand harsh chemicals and high temperatures, these stir bars not only improve the accuracy of experiments but also streamline workflows. As laboratories continue to evolve, the integration of PTFE magnetic stir bars will prove instrumental in achieving optimal results and fostering innovation within scientific research.

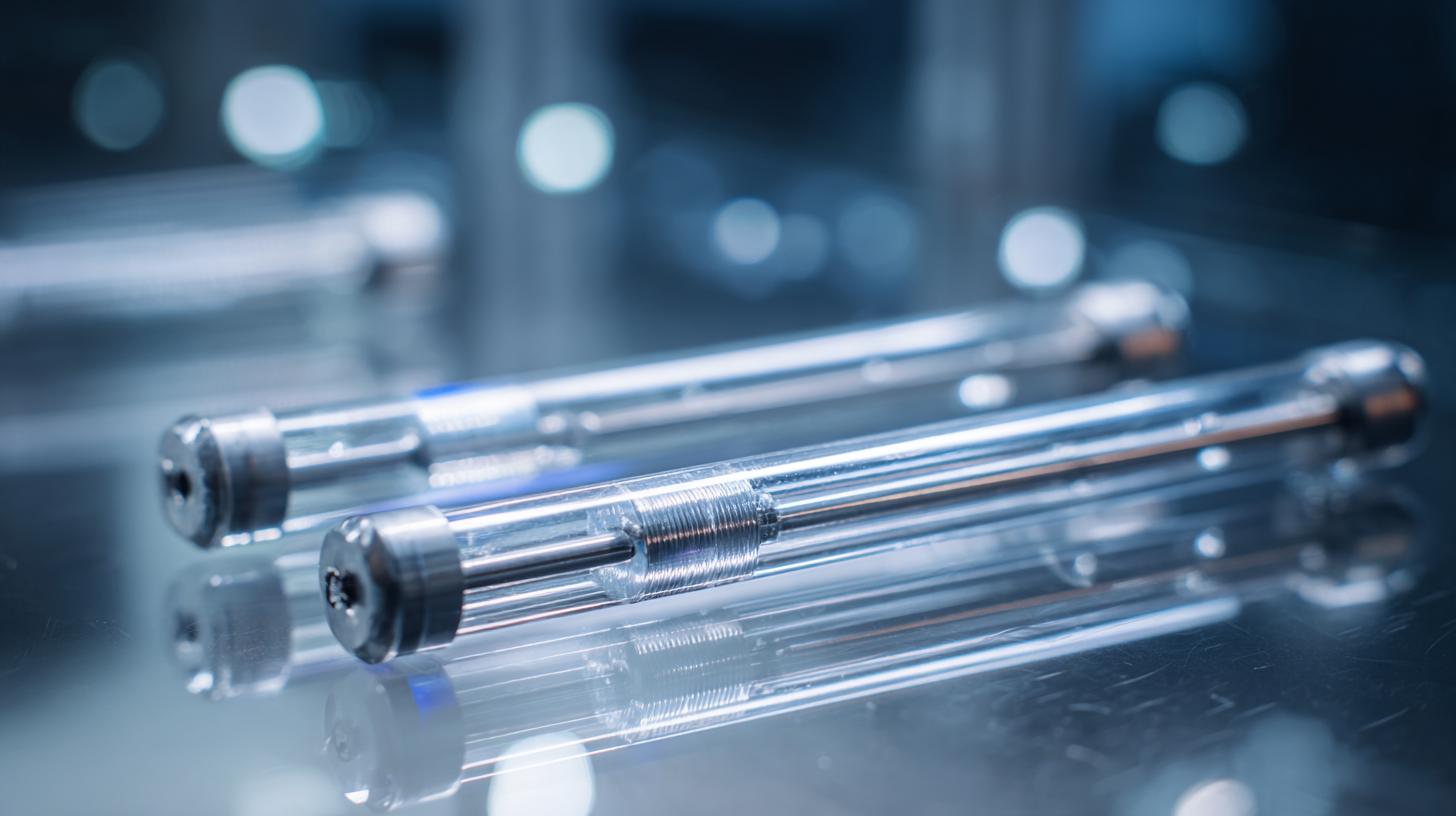

When it comes to conducting efficient chemical reactions in a laboratory setting, PTFE (Polytetrafluoroethylene) magnetic stir bars offer remarkable advantages. The unique properties of PTFE make these stir bars resistant to a wide range of chemicals, preventing any reactions that could compromise the integrity of samples. According to a report by the American Chemical Society, using PTFE stir bars can enhance reaction rates by up to 30% compared to traditional materials, leading to more efficient experiments.

In addition to their chemical resistance, PTFE magnetic stir bars are designed to create a powerful and uniform stirring action, which is essential for achieving consistent results in reactions. This uniformity reduces the chances of localized overheating or inadequate mixing, which are critical factors in the success of many chemical processes. A study from the Journal of Chemical Engineering highlights that laboratories utilizing PTFE stir bars often report a decrease in reaction times by an average of 15%, significantly boosting productivity.

**Tips:** Always ensure that your stir bar is appropriately sized for your container to optimize efficiency. It’s also beneficial to regularly check for wear and tear, as a damaged stir bar can negatively impact stirring efficiency and accuracy. Consider using PTFE stir bars in sensitive applications where contamination could drastically affect outcomes.

| Benefit | Description |

|---|---|

| Chemical Resistance | PTFE stir bars are highly resistant to a wide range of chemicals, making them suitable for aggressive solvents and reactive substances. |

| No Contamination | The non-stick surface of PTFE stir bars minimizes the risk of contamination in sensitive experiments and reactions. |

| Durability | PTFE materials are durable and can withstand high temperatures and pressures, increasing the longevity of the stir bars. |

| Uniform Mixing | PTFE magnetic stir bars provide smooth and uniform mixing, enhancing reaction efficiency and consistency. |

| Easy Cleaning | The non-adhesive characteristics of PTFE allow for easy cleaning, saving time and effort in laboratory maintenance. |

Using PTFE (Polytetrafluoroethylene) magnetic stir bars in laboratory settings offers enhanced chemical stability, making them an essential tool for various scientific applications. These stir bars are known for their excellent resistance to a wide range of chemicals, which is crucial for maintaining the integrity of experimental results. According to current industry reports, PTFE's non-reactive properties allow for consistent use in aggressive chemical environments, where traditional materials might degrade or contaminate the sample.

Research highlights that the physical and chemical degradation of PTFE can be influenced by interactions with certain materials, such as TiO2-based compounds. However, when properly utilized, PTFE stir bars minimize the risk of contamination and ensure accurate mixing results. Labs utilizing these tools can operate efficiently, reducing downtime and improving reproducibility.

Tips: Always store PTFE stir bars away from direct light and avoid prolonged exposure to high temperatures to maintain their integrity. When cleaning, use solvents that do not react with PTFE to prevent any degradation. Remember to regularly inspect your stir bars for wear, as even high-quality materials can show signs of wear over time, potentially compromising their performance.

When working in a laboratory, maintaining cleanliness and ensuring that equipment is in optimal condition is paramount.

PTFE magnetic stir bars offer a significant advantage in this regard due to their non-stick nature.

Unlike traditional stir bars, which often accumulate residues from various substances, PTFE stir bars resist the adhesion of chemicals and biological materials.

This property not only minimizes contamination risks but also significantly reduces the time and effort required for cleaning.

Moreover, the durability of PTFE material means that stir bars can withstand harsh solvents and extreme temperatures without degrading.

This resilience translates into lower maintenance requirements, as lab personnel can easily rinse or wipe the stir bars after use, keeping them ready for subsequent experiments.

By simplifying the cleaning process and enhancing their longevity, PTFE magnetic stir bars contribute to a more efficient laboratory environment, allowing researchers to focus on their work rather than the upkeep of their tools.

The use of PTFE (Polytetrafluoroethylene) magnetic stir bars in laboratories offers significant cost-effectiveness over time, making them a smart investment for various scientific applications. According to a 2022 report by the Laboratory Equipment Manufacturers Association, PTFE stir bars can endure high temperatures and resist a wide range of chemicals, drastically reducing the frequency of replacement. Traditional stir bars often require routine replacement due to wear and chemical degradation, leading to increased costs. In contrast, PTFE stir bars can last multiple years with proper care, offering substantial long-term savings.

Moreover, a study conducted by the American Chemical Society highlighted that the efficiency of PTFE magnetic stir bars could lead to reduced energy consumption in stir processes. The report indicated that optimal stirring conditions can lower reaction times and the need for additional reagents, enhancing overall laboratory productivity. Over a period of consistent use, these savings in both materials and energy can add up significantly, further validating the long-term cost benefits of incorporating PTFE magnetic stir bars into laboratory settings.

PTFE magnetic stir bars have become essential tools in laboratory settings due to their versatile applications across various experimental protocols. One of their standout features is their resistance to a broad range of chemicals, making them suitable for use in reactions involving corrosive substances. This chemical stability ensures that the stir bars do not react with the materials being mixed, maintaining the integrity of the experiments and enhancing reliability in results.

Moreover, PTFE magnetic stir bars excel in temperature-sensitive applications. With the ability to withstand high temperatures without degrading, they enable researchers to conduct heated reactions efficiently. This capability is particularly beneficial in experiments requiring precise temperature control, such as synthesizing chemicals or conducting microbiological studies. Additionally, their smooth surface facilitates easy cleaning and minimizes contamination risk between experiments, further enhancing their utility in scientific investigations.