In modern laboratories, the choice of materials can significantly impact experimental outcomes. Among various options, the PTFE Centrifuge Tube stands out due to its unique properties. PTFE, or polytetrafluoroethylene, is highly resistant to chemicals and thermal stress. A recent industry report highlighted that over 70% of laboratories prefer PTFE tubes for their reliability and durability.

Dr. Emily Rowe, a notable expert in laboratory materials, once stated, "Choosing the right centrifuge tube can make or break your experiment." This underscores the critical nature of selecting quality PTFE Centrifuge Tubes. With increasing demand for precision, the top ten tubes in this category not only enhance workflow efficiency but also reduce contamination risks.

Despite the increasing reliance on PTFE materials, not all brands offer the same reliability. It's essential to remain vigilant when selecting tubes. Some products may lack the promised durability, leading to unexpected results. As laboratories strive for excellence, the importance of a well-made PTFE Centrifuge Tube cannot be underestimated.

PTFE centrifuge tubes are essential in many laboratories. They are made from polytetrafluoroethylene, known for its chemical resistance. This material withstands harsh solvents and acids. As a result, PTFE tubes protect samples from contamination. Their durability makes them a common choice for various applications.

In research, these tubes are indispensable for centrifugation. They handle a variety of substances, from biological samples to chemical solutions. However, not all PTFE tubes are equal. Compatibility with specific solvents is vital. Users often discover that some tubes warp or degrade over time. Regular evaluation of tube performance is crucial to ensure reliability.

PTFE centrifuge tubes can also be more expensive than alternatives. This can limit accessibility for some labs. Yet, investing in quality can prevent costly mistakes. Balancing cost and performance requires careful consideration. Ultimately, the right tube choice depends on each lab's unique needs and applications.

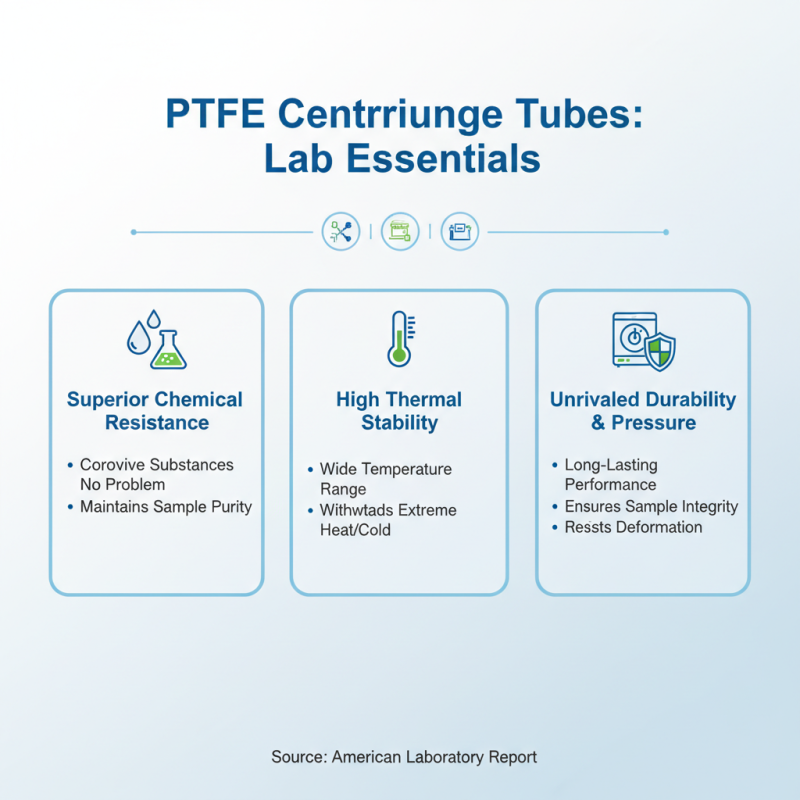

When selecting PTFE centrifuge tubes, understanding key features is crucial. One significant aspect is chemical resistance. PTFE, known for its outstanding inertness, can endure harsh solvents and corrosive substances. Reports indicate that PTFE can withstand temperatures ranging from -200°C to 260°C. This flexibility is vital for labs dealing with extreme conditions.

Another important factor is clarity. Clear PTFE tubes allow for easy sample observation. Users often prefer tubes that offer visible sample volume, ensuring accurate measurements. Brands without sufficient clarity can lead to miscalculated results. Moreover, the tube's design is essential. Sharp edges or thin walls may compromise integrity. A robust design prevents leaks and maintains sample purity.

Pricing, while often overlooked, requires close examination. Some options are significantly more expensive due to brand reputation rather than quality. It’s worth considering lower-cost alternatives that meet essential specifications. However, compromises on crucial features may pose risks. Therefore, evaluating each option against your lab's specific needs remains imperative.

When selecting PTFE centrifuge tubes, lab professionals prioritize chemical resistance and thermal stability. These attributes are essential, especially when dealing with corrosive substances. A report from the American Laboratory found that PTFE tubes outperform their alternatives in durability. They sustain pressure well, ensuring sample integrity in even the most demanding conditions.

Many users report challenges with specific models. For instance, certain tubes may struggle to fit tightly in standard rotors. Others can leak under extreme conditions. Therefore, it is crucial to examine product specifications and user feedback thoroughly. Research indicates that a well-fitting tube can reduce contamination risk by up to 30%. This factor greatly influences experimental accuracy.

Additionally, handling and storage of these tubes require careful consideration. PTFE often reacts differently based on temperature and environment. Some users may overlook proper storage or neglect tube maintenance. A small oversight can lead to significant data loss. Consequently, labs must train staff effectively to maximize the lifespan of these essential tools.

When choosing PTFE centrifuge tubes for your lab, price and value are crucial. These tubes come in various sizes and designs. Basic options are often more affordable but may lack some advanced features. Conversely, higher-end models typically offer enhanced durability and precision. The price range can vary significantly, so it’s essential to analyze your budget.

Consider the volume you need. Smaller tubes might cost less, but they require more handling. Larger tubes can be more efficient for batch processing. It's interesting how the perceived value can differ based on the lab’s specific needs. Some users find that inexpensive tubes leak more often, leading to wasted samples. In contrast, investing in slightly costlier tubes may save money long-term due to their reliability.

Many labs often overlook these details. A lower price can lead to frustrations, like inconsistent results. Review your options to ensure you find the best balance. Think critically about your lab's workflow. Gathering feedback from colleagues can also provide insights into cost-effectiveness and usability. Challenges in choosing the right tube may lead to missed opportunities for improvement. Careful consideration can enhance productivity.

Proper care and maintenance of PTFE centrifuge tubes are essential for ensuring reliable results in the lab. Regular inspections can help identify wear or damage early. Check tubes for cracks or discoloration. These signs often indicate that the tubes need replacing. If you notice any issues, don't hesitate to discard them. It’s better to be safe than to risk contamination.

Cleaning is equally important. After use, rinse the tubes with distilled water. This helps remove residual substances. If heavy contaminants are present, consider using a mild detergent. Avoid abrasive materials; they can scratch the surface. It’s advisable to air-dry the tubes to prevent water spots. Remember, improper drying may lead to the growth of unwanted bacteria.

Storage conditions can also influence the longevity of your tubes. Store them upright in a clean, dry place. Avoid extreme temperatures and direct sunlight, as they can degrade PTFE material. It’s easy to overlook these details, but they can make a significant difference. Keep a careful eye on all aspects of tube maintenance for optimal performance.

| Model | Volume (ml) | Max RPM | Temperature Range (°C) | Autoclavable | Price (USD) |

|---|---|---|---|---|---|

| PTFE Tube Model A | 15 | 15000 | -80 to 250 | Yes | 35.00 |

| PTFE Tube Model B | 50 | 14000 | -60 to 230 | Yes | 45.00 |

| PTFE Tube Model C | 100 | 13000 | -70 to 240 | Yes | 50.00 |

| PTFE Tube Model D | 200 | 12000 | -80 to 260 | No | 60.00 |

| PTFE Tube Model E | 250 | 11000 | -60 to 250 | Yes | 70.00 |

| PTFE Tube Model F | 500 | 10000 | -50 to 240 | Yes | 85.00 |

| PTFE Tube Model G | 1000 | 9000 | -40 to 250 | No | 95.00 |

| PTFE Tube Model H | 1500 | 8500 | -60 to 230 | Yes | 110.00 |

| PTFE Tube Model I | 2000 | 8000 | -70 to 240 | Yes | 125.00 |

| PTFE Tube Model J | 3000 | 7000 | -80 to 250 | No | 150.00 |