When it comes to equipping a laboratory for optimal efficiency and reliability, choosing the right tools is paramount. Among these essential instruments, the Ptfe Magnetic Stirrer stands out due to its versatility and effectiveness in mixing various solutions. The year 2025 brings advancements in laboratory technology, making it crucial for researchers to be informed about the features and specifications that the best Ptfe Magnetic Stirrer can offer. This device not only improves the mixing process but also ensures that chemical reactions occur uniformly, which is vital for achieving accurate results.

As laboratories become more sophisticated, the range of available Ptfe Magnetic Stirrers has expanded, each tailored to meet specific laboratory needs. Potential buyers must consider factors such as durability, ease of use, and efficiency when selecting a stirrer. Furthermore, understanding how a Ptfe Magnetic Stirrer operates—particularly its temperature resistance and chemical compatibility—can significantly influence the performance and longevity of laboratory equipment. Therefore, this guide will provide insights on how to effectively evaluate and choose the right Ptfe Magnetic Stirrer to enhance your laboratory’s productivity and success.

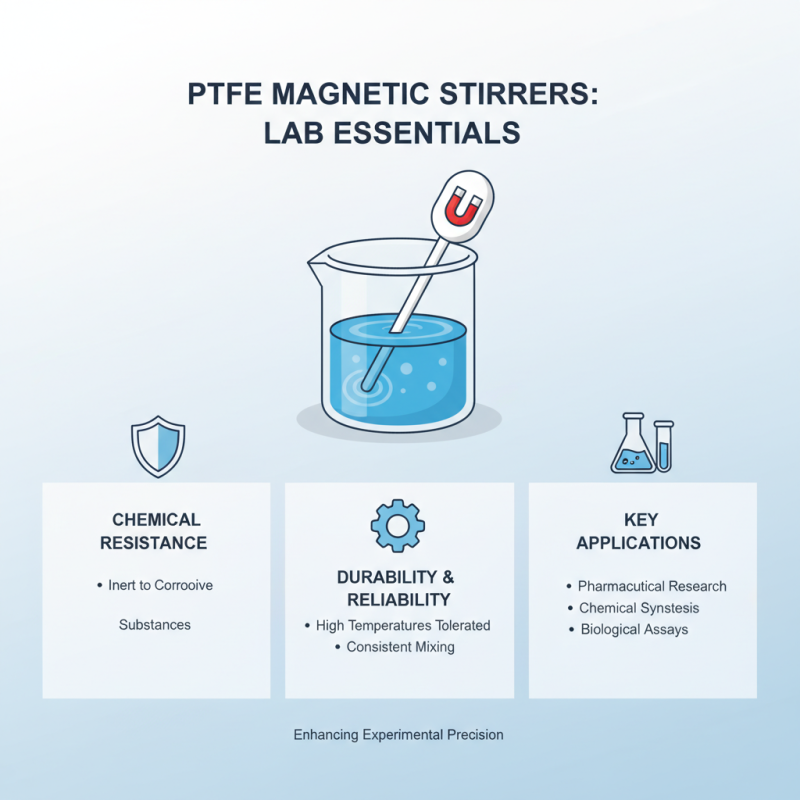

PTFE (Polytetrafluoroethylene) magnetic stirrers are essential tools in laboratories, known for their chemical resistance and durability. They are particularly useful in applications involving corrosive substances or high-temperature solutions. By ensuring a consistent and efficient mixing process, PTFE magnetic stirrers enhance the reliability of experimental results, making them indispensable in pharmaceutical, chemical, and biological research settings.

When selecting a PTFE magnetic stirrer, consider the specific requirements of your laboratory. Factors such as the volume of liquid to be stirred, the viscosity of the solution, and the desired temperature range play crucial roles. Additionally, the quality of the stirrer's magnetic coupling and its stirring speed range can significantly impact performance. Look for models that offer adjustable speeds and reliable temperature control to accommodate various applications.

**Tips:** Always verify that the materials used are compatible with the substances you'll be mixing. It’s also beneficial to opt for a stirrer with a robust design to withstand frequent use. Regular maintenance, including cleaning the PTFE surfaces, ensures longevity and optimal performance.

When selecting a PTFE magnetic stirrer for laboratory applications, several key features must be taken into account to ensure optimal performance. One of the primary factors is the stirring capacity, which typically ranges from 1 to 20 liters. According to a recent industry report, nearly 62% of laboratories prioritize the volume of liquid that can be effectively stirred when making their selection. It's crucial to choose a model that suits the specific needs of your experiments without compromising the integrity of the samples.

Another significant feature to consider is the temperature range and control. Many modern PTFE magnetic stirrers offer precise temperature controls that can be crucial when dealing with sensitive chemical reactions. Reports indicate that 58% of researchers find temperature stability essential to avoid error in their results. Additionally, the material construction – specifically the PTFE coating – is pivotal as it enhances chemical resistance, ensuring longevity and reliability in various experimental conditions. The ease of cleaning and maintenance is also a prominent consideration, with over 70% of lab professionals reporting that ease of use significantly impacts their choice of equipment.

When selecting a PTFE magnetic stirrer for laboratory use, evaluating the efficiency and performance of different models is crucial. A recent study published in the Journal of Laboratory Automation highlights that the stirring speed, range of volume, and temperature resistance play significant roles in a stirrer’s overall effectiveness. For instance, models that offer variable speed settings can accommodate a wider range of applications, from gentle mixing to vigorous stirring required in chemical reactions. The reported optimal speed range is typically between 100 to 1500 RPM, allowing for versatility depending on the viscosity of the liquids being mixed.

Moreover, the materials and construction of a PTFE magnetic stirrer greatly influence its performance. According to data from the American Chemical Society, stirrers made with high-quality PTFE not only resist chemical corrosion but also demonstrate superior durability under high temperatures, often up to 250°C. This quality is vital in chemistry and biochemistry labs where harsh solvents and high heat are commonplace. Additionally, models equipped with advanced safety features, such as automatic shut-offs and temperature controls, are becoming standard, promoting both laboratory safety and efficiency in experiments. Careful consideration of these factors ensures that laboratories can achieve optimal performance while minimizing risks associated with equipment failure or inappropriate mixing.

When operating a PTFE magnetic stirrer in your laboratory, proper maintenance and care are crucial for ensuring longevity and optimal performance. Regular cleaning is essential to prevent contamination and ensure accurate results. After each use, rinse the stirrer with distilled water to remove any residual samples. Avoid harsh solvents that could damage the PTFE coating. Instead, use a soft cloth or brush to wipe down surfaces, and regularly check for any signs of wear or damage.

Additionally, it’s important to periodically inspect the stirring bar and the motor. The stirring bar should be free of chips or scratches, as these can affect performance. Store the stirrer in a clean, dry area to avoid dust buildup, and ensure all connections are secure to prevent electrical malfunctions. By following these maintenance practices, you can enhance the efficiency and reliability of your PTFE magnetic stirrer, ultimately contributing to the success of your laboratory experiments.

| Feature | Description | Maintenance Tips |

|---|---|---|

| Speed Range | Typically ranges from 100 to 2000 RPM. | Regularly check and calibrate the speed if necessary. |

| Heating Capability | Some models come with built-in heating features up to 300°C. | Ensure heaters are functioning and clean to maintain efficient heating. |

| Volume Capacity | Best for volumes from 50 mL to 5 L. | Avoid exceeding recommended volume to prevent overflow. |

| Material Quality | PTFE is chemically resistant and easy to clean. | Use gentle cleaners and avoid abrasive materials. |

| Power Supply | Most operate on standard 110-220V AC power. | Check power cords for wear and tear regularly. |

| Noise Level | Modern stirrers are designed to minimize noise. | Keep the device on a stable surface to reduce vibrations. |

When selecting a PTFE magnetic stirrer for laboratory needs, it's crucial to consider pricing and budget to ensure that the investment aligns with operational requirements. According to recent industry reports, the average cost of a high-quality PTFE magnetic stirrer ranges from $200 to $1,500, depending on features and specifications. As laboratory budgets can significantly vary, performing a comparative analysis of potential options can help identify a device that meets performance needs without overshooting financial limits.

A comprehensive evaluation of purchasing decisions should include not only the initial cost but also long-term budget considerations such as maintenance and operational efficiency. Reports indicate that investing in higher-end models can lead to reduced wear and tear and lower replacement rates, thereby offering better value in the long run. Additionally, sophisticated models with enhanced durability typically feature improved magnetic coupling, leading to more consistent stirring outcomes and a decreased likelihood of equipment failure. By balancing upfront costs with these longer-term savings, laboratories can more effectively allocate their budgets and optimize resource utilization.