Choosing the right magnets PTFE stirrer bars can be a daunting task, especially with the myriad of options available in the market today. These essential laboratory tools play a crucial role in ensuring efficient stirring and mixing of liquid samples, impacting the accuracy and reliability of experimental results. However, the decision-making process can be complicated by factors such as material compatibility, size, magnetic strength, and specific application requirements. In this blog, we will delve into the challenges associated with selecting the best magnets PTFE stirrer bars, offering insights and tips to navigate through the various types and options available. By understanding these challenges, researchers and laboratory professionals can make informed choices that enhance their workflows and optimize experimental outcomes.

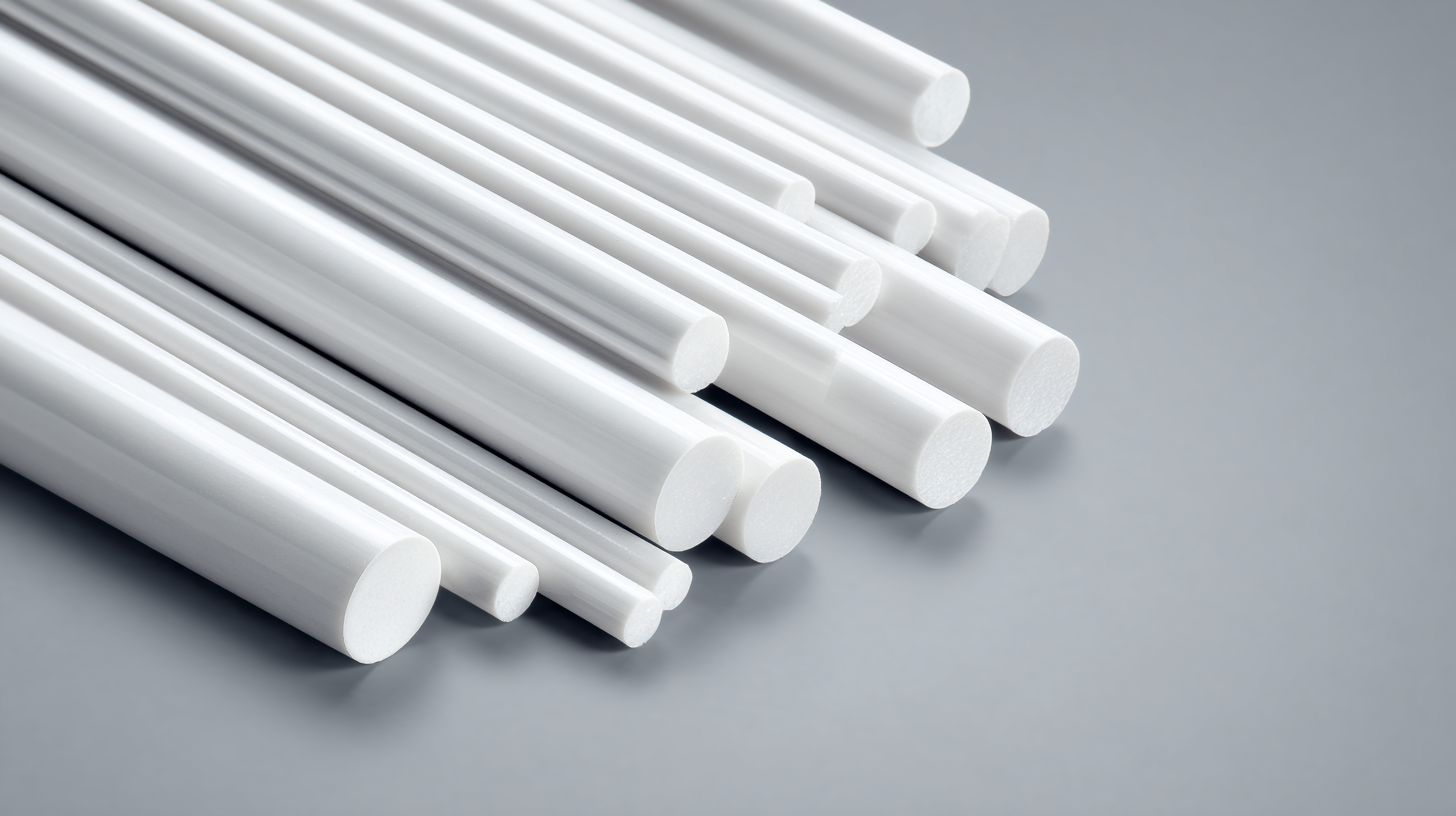

When selecting PTFE stirrer bars for your specific needs, there are several key factors to consider. First and foremost is the size and shape of the stirrer bar. The dimensions should match the vessel you are using, ensuring effective mixing without causing damage. For instance, longer bars may be suitable for larger containers, while smaller ones are ideal for narrower flasks. Additionally, the shape of the stirrer can influence the mixing efficiency; a rectangular bar may provide better interaction with the liquid compared to a cylindrical one.

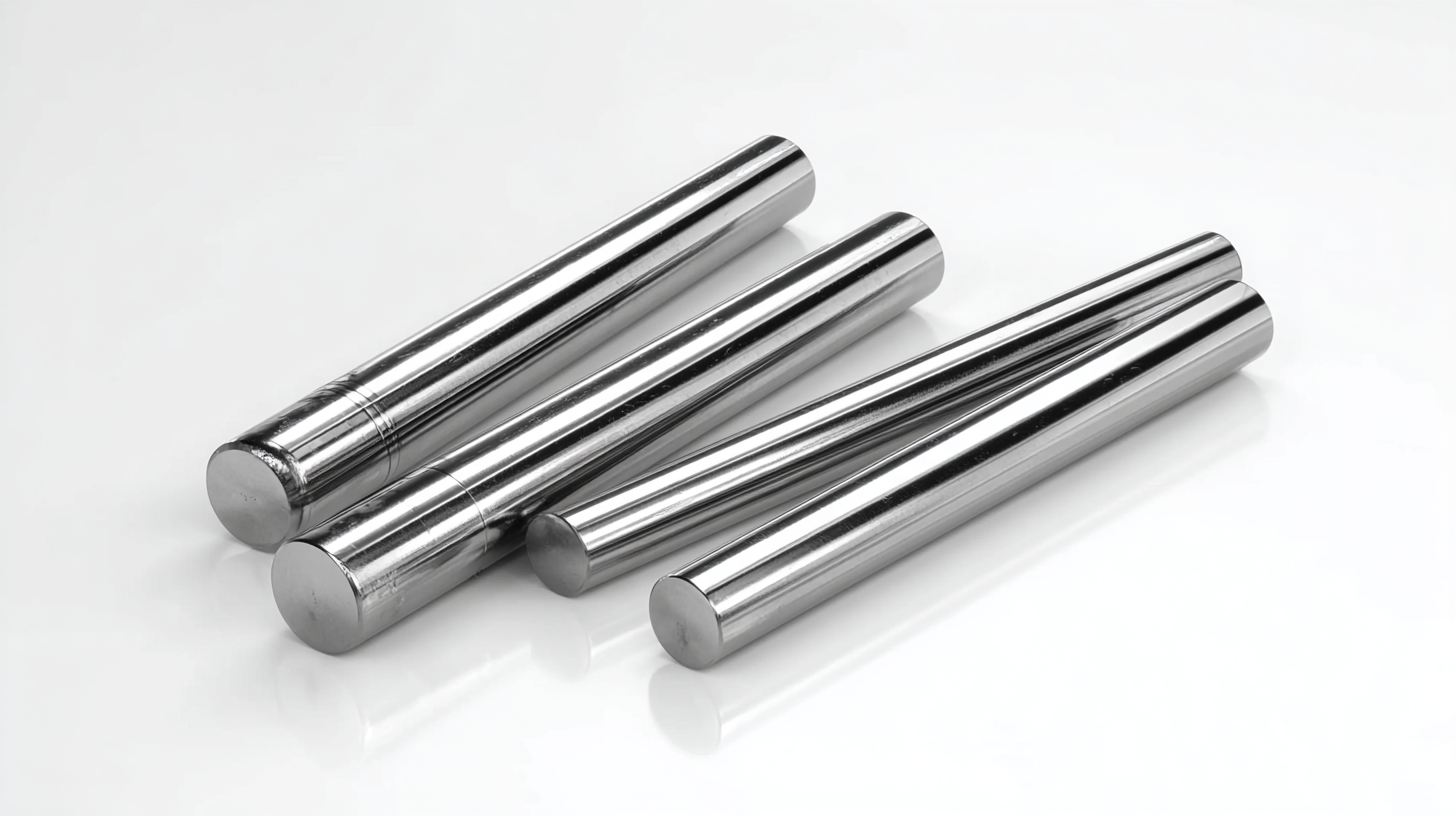

Another critical factor involves the magnetic strength of the stirrer bars. It's essential to choose bars with adequate magnetic properties to ensure they remain engaging with the stirrer plate throughout the mixing process. This ensures consistent stirring without interruptions. Beyond that, the chemical compatibility of PTFE with the liquids being stirred must also be assessed. PTFE is known for its resistance to a wide range of chemicals, but verifying compatibility can prevent unforeseen reactions and prolong the lifespan of your stirrer bars. Keeping these elements in mind will aid in selecting the best PTFE stirrer bars tailored to your mixing requirements.

| Dimension | Material Quality | Magnet Strength | Temperature Resistance | Stirring Efficiency |

|---|---|---|---|---|

| 10 mm | High-quality PTFE | Strong Magnet | -200°C to +260°C | Optimal |

| 15 mm | Standard PTFE | Moderate Magnet | -150°C to +200°C | Good |

| 20 mm | Premium PTFE | Very Strong Magnet | -250°C to +300°C | Excellent |

| 25 mm | High-quality PTFE | Strong Magnet | -200°C to +260°C | Optimal |

When selecting the ideal stirrer bars for various magnetic applications, it's crucial to explore alternatives to traditional magnets. One popular option is the use of ceramic stirrer bars, which provide a cost-effective and non-corrosive solution. These bars are made from durable materials that withstand harsh chemical environments, making them ideal for laboratories and industrial settings. Their ability to maintain stability and perform efficiently in a wide range of temperatures makes them a reliable choice for stirring solutions.

Another alternative gaining traction is the use of high-performance magnetic stirrer bars created from rare earth materials. These stirrers offer significantly stronger magnetic fields than their conventional counterparts, enabling faster stirring rates and greater precision in experiments. Such advancements are particularly beneficial for applications requiring rigorous mixing or those dealing with viscous materials. By considering these alternatives, users can enhance their workflow while maintaining operational efficiency in their experiments or processes.

When it comes to laboratory stirring applications, PTFE stirrer bars have carved out a niche due to their unique properties. PTFE, or polytetrafluoroethylene, is known for its exceptional chemical resistance and low friction characteristics, making it an ideal choice for working with aggressive solvents and corrosive materials. In a comparative analysis, PTFE stirrer bars often outperform traditional glass or metal stirrers, as they minimize contamination and enhance the purity of the solution.

However, it's essential to consider the limitations of PTFE stirrer bars as well. While they excel in specific applications, such as stirring delicate or reactive substances, they may not be suitable for all scenarios. Other stirring methods, like mechanical stirrers or magnetic stirrers with different materials, can provide robust solutions for more complex or viscous mixtures. When choosing the right stirring method, laboratory professionals must weigh the specific requirements of their experiments, including the nature of the compounds being stirred, the desired mixing efficiency, and any potential interactions with the stirrer material. Ultimately, the decision should align with the experimental goals and safety considerations in the lab.

When selecting the right magnetic stirrer bars for various applications, understanding the benefits and drawbacks of different options is crucial. Traditional magnetic stirrers offer reliability and ease of use, but advancements in materials have introduced innovative alternatives. Recent developments in producing polymer-coated magnetic nano-stirrer bars through continuous electrospinning allow for enhanced performance in challenging environments. These nano-stirrers not only provide effective mixing at the microscale but also boast durability against harsh conditions, making them suitable for complex chemical reactions in laboratories.

Moreover, magnetic nanomaterials present a sustainable solution for environmental challenges. Research shows that magnetic nanoparticles (MNPs) can effectively adsorb hazardous contaminants from wastewater with lower maintenance requirements compared to conventional adsorbents. By incorporating such nanomaterials into magnetic stirring systems, users can achieve efficient mixing while also addressing environmental sustainability. A growing focus on greener alternatives highlights the importance of selecting magnetic stirrer bars that not only cater to performance needs but also align with eco-friendly practices in scientific and industrial settings.

When selecting quality PTFE stirrer bars, several key specifications should be taken into account to ensure optimal performance in laboratory settings. First and foremost is the size and shape of the stirrer bars. They come in various lengths and diameters, which directly affect their mixing efficiency. A properly sized stirrer bar will provide better magnetic coupling and facilitate effective stirring of different volumes of liquids.

Another critical specification is the magnetic strength of the stirrer bars. The magnet's strength determines how well it can be held in place while stirring, especially in viscous fluids. Choosing a stirrer bar with a robust magnet will reduce the likelihood of slippage during operation, resulting in more consistent results. Additionally, the quality of the PTFE coating is essential; it not only provides chemical resistance but also enhances the durability and longevity of the stirrer bars, allowing them to withstand harsh environments without degradation. By focusing on these specifications, users can select the right PTFE stirrer bars that meet their specific laboratory needs.