When it comes to optimizing laboratory operations, selecting the right PTFE Centrifuge Tube is crucial for achieving accurate and reliable results. As laboratories often require highly specialized equipment, understanding the alternatives available in the market can significantly impact your experimental outcomes.

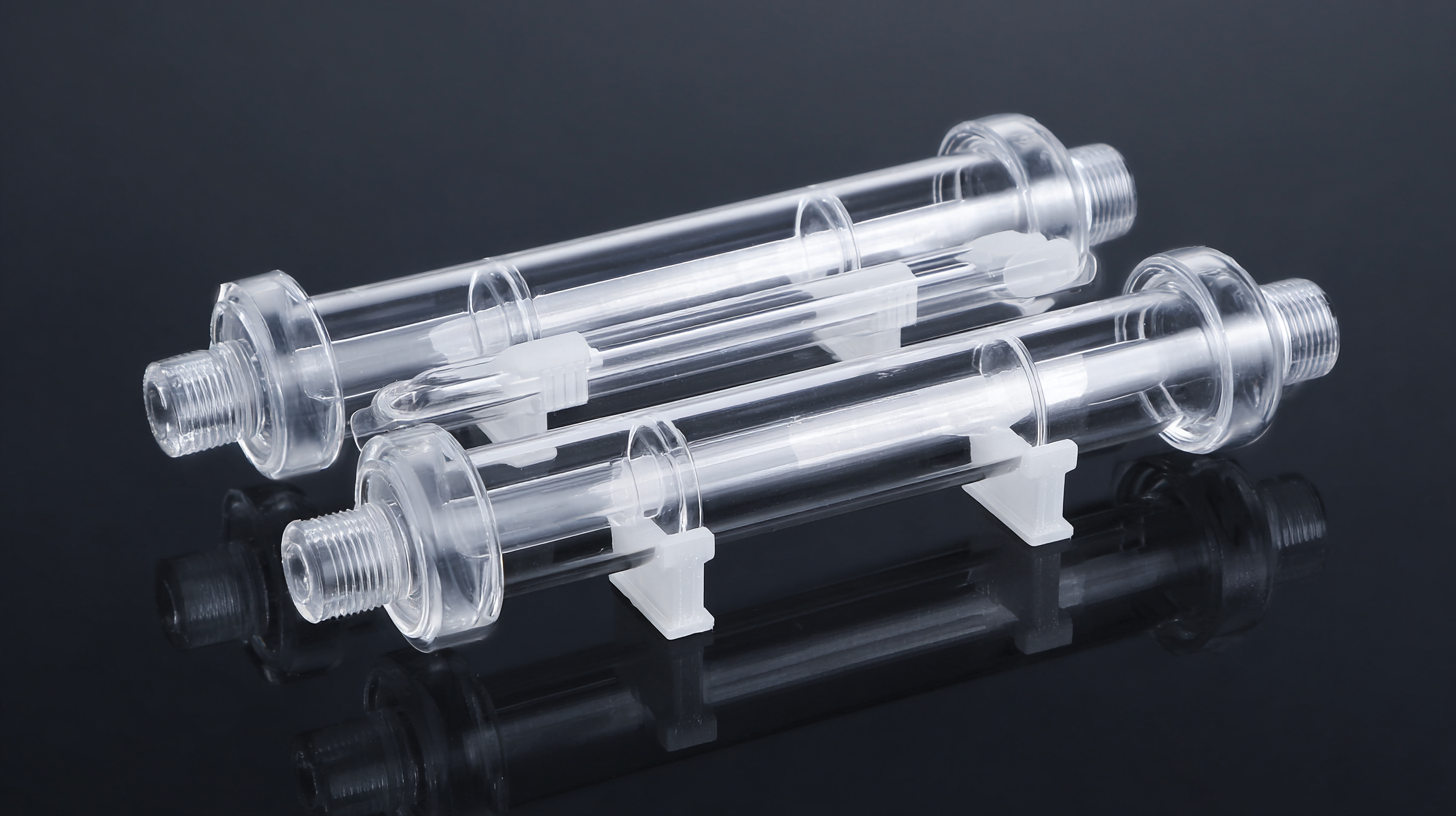

PTFE Centrifuge Tubes stand out for their chemical resistance and low friction properties, making them ideal for applications involving aggressive solvents or sensitive samples. However, with numerous alternatives available, ranging from traditional plastic tubes to high-performance glass options, it’s essential to evaluate which type aligns with your specific lab needs.

This ultimate checklist will guide you through critical factors to consider when selecting a PTFE Centrifuge Tube, helping you make an informed choice to enhance your lab's efficiency and effectiveness.

PTFE Centrifuge Tubes stand out for their chemical resistance and low friction properties, making them ideal for applications involving aggressive solvents or sensitive samples. However, with numerous alternatives available, ranging from traditional plastic tubes to high-performance glass options, it’s essential to evaluate which type aligns with your specific lab needs.

This ultimate checklist will guide you through critical factors to consider when selecting a PTFE Centrifuge Tube, helping you make an informed choice to enhance your lab's efficiency and effectiveness.

When selecting the best PTFE centrifuge tubes for your laboratory needs, several critical factors must be considered to ensure that you make an informed choice. The chemical compatibility of the tubes is paramount; PTFE is known for its exceptional resistance to a wide range of chemicals, making it a popular choice in labs handling aggressive solvents or acids. Additionally, it’s essential to consider the temperature tolerance of the tubes, as PTFE materials can withstand high temperatures, which is crucial for certain applications that involve heat-sensitive samples.

Another significant aspect to evaluate is the tube's certification and quality assurance. Choosing PTFE centrifuge tubes that meet industry standards can enhance reliability and ensure that your results are accurate. Furthermore, consider the volume capacity, design features such as snap caps or screw tops, and how these factors might align with the specific protocols and experiments being conducted in your lab. As the demand for PTFE products skyrockets, with the global PTFE membrane market projected to grow significantly by 2032, investing in the right centrifuge tubes will be essential for laboratories aiming for the highest level of performance and safety in their experimental procedures.

| Factor | Description | Typical Range/Measured Value |

|---|---|---|

| Material Composition | Quality of PTFE used in manufacturing | 99% purity or higher |

| Volume Capacity | Amount of liquid the tube can hold | 1.5 mL, 15 mL, 50 mL |

| Temperature Resistance | Ability to withstand extreme temperatures | -196°C to 260°C |

| Centrifuge Compatibility | Compatible rotor types for centrifugation | Fixed-angle, Swing-out |

| Autoclavability | Can the tube be sterilized by autoclaving? | Yes, often ≥121°C |

| Chemical Resistance | Resistance to solvents, acids, and bases | Highly resistant to most chemicals |

| Sealing Mechanism | Type of closure to prevent leaks | Screw caps, snap-on lids |

| Cost | Average price per tube | $0.50 - $5.00 |

| Certifications | Industry standards met by the tubes | ISO, CE marked |

When selecting a PTFE centrifuge tube, it's crucial to understand the differences between the various types available, as each has its own set of advantages and drawbacks. For instance, standard PTFE centrifuge tubes are known for their excellent chemical resistance and durability, making them suitable for a wide range of laboratory applications. However, their relatively higher cost may deter some users, especially in budget-sensitive environments.

On the other hand, modified PTFE tubes offer enhanced mechanical properties and can withstand higher temperatures, which can be beneficial for specific experimental conditions. The trade-off often lies in their limited chemical resistance, making them less ideal for aggressive solvents.

Additionally, disposable PTFE tubes are an excellent option for labs focused on contamination control, as they eliminate the need for cleaning and reusing, although they may lead to increased waste over time. Understanding these pros and cons helps laboratories make informed decisions that align with their specific needs and criteria, ensuring they choose the right PTFE centrifuge tube for their applications.

When selecting a high-quality PTFE centrifuge tube for your laboratory, it's crucial to focus on key specifications that ensure optimal performance and longevity. First and foremost, consider the tube's chemical resistance. PTFE (polytetrafluoroethylene) is renowned for its ability to withstand harsh chemicals, making it ideal for experiments involving aggressive solvents or corrosive substances. Ensure that the tubes you choose are compatible with the specific reagents you plan to use, as this will prevent any potential reactions that could compromise your samples.

Another important aspect to evaluate is the temperature tolerance of the centrifuge tubes. High-quality PTFE tubes typically exhibit excellent thermal stability and can endure a wide range of temperatures, from cryogenic conditions to high-heat applications. This feature is particularly beneficial for studies that involve extreme temperature fluctuations. Additionally, pay attention to the tube's volume capacity and design features such as sealing mechanisms. A well-designed tube will not only allow for easier handling and transportation of samples but also minimize leakage risks, ensuring accurate results and maintaining the integrity of your experiments.

PTFE (Polytetrafluoroethylene) centrifuge tubes are increasingly becoming essential tools in various laboratory applications due to their unique chemical resistance and thermal stability. Commonly used in fields such as biochemistry, pharmaceuticals, and environmental testing, these tubes can handle aggressive chemicals, making them perfect for applications like sample storage, protein precipitation, and nucleic acid isolation. Recent industry reports indicate that the demand for PTFE products has grown by approximately 15% annually, highlighting their significance in laboratory settings.

When selecting PTFE centrifuge tubes, keep in mind the working temperature and the specific chemicals you will be using. PTFE can withstand temperatures up to 260°C, allowing for a wide range of applications, including those that require high-temperature centrifugation. Additionally, ensure that the tubes have compatible volume capacities and are designed for your centrifuge model.

**Tip:** Always verify the compatibility of PTFE tubes with your sample types. Some compounds may interact differently, and performing a preliminary test can save time and resources in the long run.

Moreover, PTFE centrifuge tubes are notable for their lightweight design and low friction, which improves centrifugation efficiency. They are also resistant to sticking, minimizing sample loss and contamination. For optimal results, look for tubes that are certified for specific laboratory standards and ensure they provide detailed application guidelines.

When it comes to selecting PTFE centrifuge tubes for your lab needs, budgeting can significantly impact your final decision. Industry reports indicate that the average cost of high-quality PTFE tubes can range from $2 to $10 per unit, depending on size and specifications. Labs should assess their budget while also considering the durability and chemical resistance of the materials. Investing in higher-grade tubes may save costs in the long run due to less frequent replacements and increased resistance to harsh chemicals.

When formulating your budget, it's also essential to consider the suppliers' reputation and customer service. Many reputable suppliers offer bulk purchasing options, which may provide greater savings and ensure that your lab is well-stocked with the necessary supplies. A recent analysis revealed that labs that engaged with suppliers for bulk discounts saw an average savings of 15-20% on their overall supply costs. By carefully budgeting and selecting the right suppliers, you can optimize your lab expenses while securing reliable and efficient PTFE centrifuge tubes for your research needs.