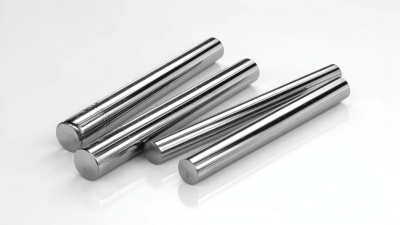

In the fast-evolving world of laboratory equipment, choosing the right tools is crucial. Among these, "Magnets Ptfe Stirrer Bars" stand out for their efficiency and durability. A recent report by the Laboratory Equipment Analyst highlights a growing demand for PTFE-coated stirrer bars. The report indicates a 25% increase in usage over the past year, showcasing their importance in various lab settings.

Dr. Emily Carter, a leading expert in laboratory technology, emphasizes the advantages of these stirrer bars: "Magnets Ptfe Stirrer Bars provide unmatched stability and versatility." Her words capture the essence of why labs are opting for these innovative solutions. Yet, while many understand their benefits, some researchers still underestimate their potential in optimizing mixing processes.

Moreover, the ongoing challenges with traditional stirring methods highlight the need for modern alternatives. Users often face issues like contamination, which can compromise results. In contrast, "Magnets Ptfe Stirrer Bars" mitigate such risks, enhancing accuracy. Therefore, labs need to reflect on their current practices and consider investing in these valuable tools to elevate their research outcomes.

Using PTFE-coated magnet stirrer bars in laboratories offers numerous advantages. They are known for their chemical resistance, making them ideal for a variety of solutions. The PTFE coating prevents reactions with corrosive substances. As a result, researchers can work confidently without worrying about contamination. These stirrer bars also provide smooth stirring. They create a uniform mixture, which is essential for accurate experiments.

Another benefit lies in their durability. PTFE is a robust material that withstands wear and tear over time. This longevity can save costs on replacements. The smooth surface of PTFE bars reduces friction, enhancing their performance in stirring tasks. However, one must ensure proper cleaning to maintain their effectiveness. Residue can still cling on, impacting results.

Despite these advantages, some users face challenges. For instance, finding the right size and shape can be tricky. It's crucial to consider your specific setup. Additionally, not every task may require a PTFE-coated bar. In some cases, standard stirrer bars might suffice. Careful evaluation of lab needs is key to making the right choice.

| Feature | Benefits |

|---|---|

| Chemical Resistance | PTFE coating protects against corrosive substances, ensuring longevity. |

| Non-Stick Surface | Prevents sample adherence, allowing for easy cleaning and maintenance. |

| Temperature Resistance | Can withstand a wide range of temperatures without degrading. |

| Uniform Mixing | Ensures consistent and thorough mixing of samples. |

| Versatility | Suitable for various laboratory applications and liquids. |

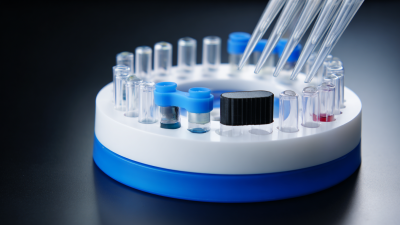

Magnet PTFE stirrer bars are essential in many laboratories. They provide efficient and reliable mixing solutions. These bars are made from polytetrafluoroethylene (PTFE), which ensures chemical resistance. This is critical when working with reactive substances. Their smooth surface minimizes contamination risks, making them ideal for high-purity applications.

These stirrer bars offer unique features. They are designed to operate quietly within the vessel. The strong magnetic properties create a powerful mixing action. This enhances the uniformity of solutions. Users often find that magnetic stirrer bars improve workflow efficiency. However, selecting the right size is crucial. A bar that is too small may not mix effectively. This can lead to inconsistent results, requiring further adjustments.

While the benefits are clear, there are challenges. Contamination can still occur if the vessel is not clean. Users need to ensure thorough cleaning before use. Regular inspection of the stirrer bars is necessary too. Over time, wear can affect their performance. Refining the mixing process often involves trial and error. Learning from these experiences will lead to better results in future experiments.

When comparing PTFE stirrer bars to traditional stirrer bars, several factors come into play. PTFE stirrer bars are made from polytetrafluoroethylene, offering excellent chemical resistance. This makes them suitable for various laboratory applications, especially when working with corrosive substances. In contrast, traditional stirrer bars can corrode or react, compromising experiment integrity.

Another distinguishing feature is heat resistance. PTFE stirrer bars can withstand higher temperatures. This is crucial for processes that involve heat. Traditional stirrer bars may melt or deform, disrupting experiments. While PTFE is more durable, it's essential to note that it may not always be the first choice for every situation. Some users find them difficult to clean if they are not handled promptly.

Cost is another consideration. PTFE stirrer bars tend to be more expensive than traditional options. For labs on a budget, this may present a challenge. Balancing durability, price, and application needs can be tough. Experimentation with both types can help users discern the best fit for their unique laboratory requirements.

Magnet stirrer bars are essential tools in scientific laboratories. Their effectiveness spans various fields, including chemistry and biology. In chemistry, they facilitate mixing complex solutions. A well-known study reveals that the efficiency of stirring can enhance reaction rates by up to 40%. This is critical for reactions requiring precise conditions.

In the biological sciences, magnet stirrers support cell culture and media preparation. Accurate mixing is vital for growth media. Studies show that uneven mixing can lead to nutrient gradients, affecting cell health. Some researchers argue that not all solutions mix well with traditional methods. Although magnet stirrer bars are efficient, they may not work for very viscous liquids. This limitation can force scientists to seek alternatives, sometimes sacrificing efficiency for effectiveness.

Environmental science also benefits from magnet stirrers. They are used in water quality testing. Mixing samples thoroughly is crucial for accurate measurements. Reports suggest that improper mixing can lead to misleading results. Thus, laboratories must be cautious in selecting their mixing methods. Not all instruments are reliable for every application. Continuous reflection and adaptation are necessary for optimal laboratory performance.

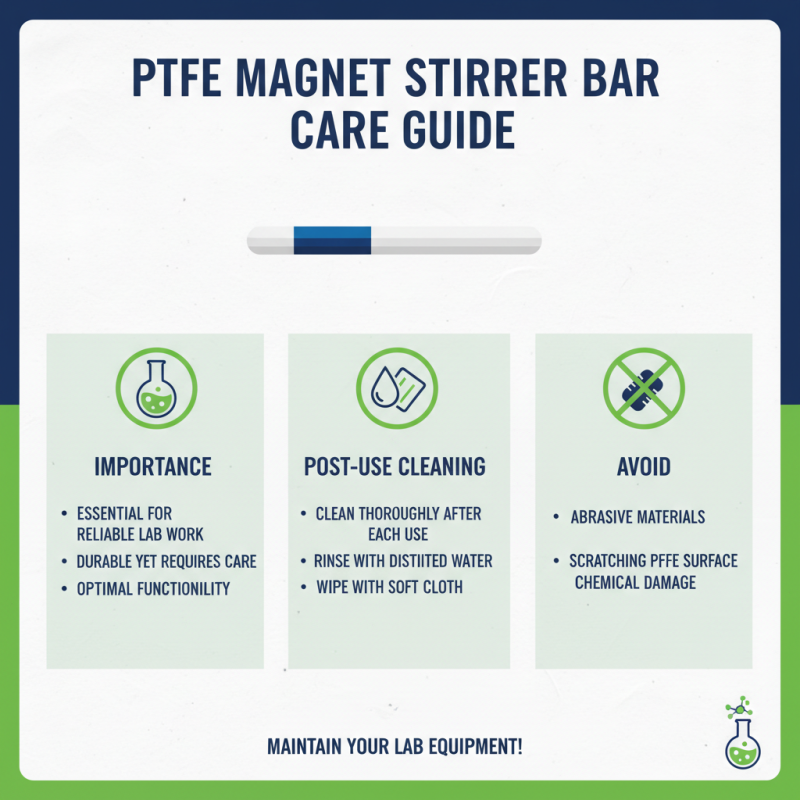

Maintaining PTFE magnet stirrer bars is essential for reliable lab work. These stirrers are durable but require care to function optimally. After each use, clean them thoroughly. Rinse with distilled water, and use a soft cloth to wipe them down. Avoid abrasive materials that can scratch the PTFE surface.

Tips: Always store your stirrer bars in a designated container. This prevents them from getting damaged or lost. Regular inspections can help identify any wear or cracks. If you notice any issues, consider replacing them.

Remember not to expose these stirrers to extreme temperatures. High heat can deform the PTFE, affecting performance. Be mindful of the solvents you use, as some can degrade the material. Using compatible substances ensures your stirrers last longer. Over time, you’ll notice how proper care enhances their efficiency.