Choosing the right equipment is essential for any laboratory. One critical device is the PTFE stirrer. It is widely used for mixing various substances. However, selecting the correct PTFE stirrer can be challenging. There are multiple factors to consider.

PTFE stirrers come in different sizes and shapes. Their materials also vary, affecting durability and effectiveness. For example, some are designed for high-temperature applications, while others suit lower temperatures. Understanding these differences matters. It impacts your experiments and results significantly.

In addition, think about your specific needs. Do you require a stirrer with a certain resistance to chemicals? Are you working with abrasive materials? Asking these questions helps refine your choices. Remember, a poorly chosen PTFE stirrer can lead to inefficiency. Sometimes, it’s easy to overlook details. Reflection can help avoid common pitfalls in the selection process.

When selecting a PTFE stirrer for laboratory applications, understanding the material is crucial. PTFE, or polytetrafluoroethylene, is known for its unique properties. It is resistant to chemicals, making it ideal for various substances. This resistance allows the stirrer to function effectively without degrading. However, it is important to note that not all PTFE is the same. Variations in purity and manufacturing methods can impact performance.

Consider the physical characteristics of PTFE stirrers. They are often lightweight and durable, perfect for laboratory tasks. Their non-stick nature means that materials don't adhere easily. This aspect is especially useful when working with viscous or sticky substances. Still, it's worth reflecting on the limitations, such as susceptibility to deformation under extreme temperatures. Sometimes users find that they need extra care during high-temperature operations.

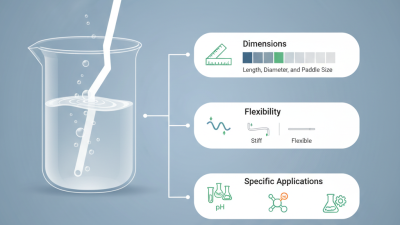

Another aspect to think about is the design of the stirrer. PTFE stirrers come in various shapes and sizes, tailored for different containers. A standard design may not fit well with all vessels. Users should pay attention to compatibility before making a purchase. This requires careful measurements and consideration of lab dynamics. While PTFE stirrers are versatile, the nuances of each laboratory setup must guide the final choices.

When selecting a PTFE stirrer for your lab, several key factors must be considered. The size of the stirrer is crucial. A larger stirrer may be needed for bigger containers. Conversely, smaller vessels require compact designs. Make sure the stirrer fits well in the container. This impacts the efficiency of mixing.

Material compatibility is another important factor. PTFE stirrers resist chemicals and high temperatures. However, always check your specific application requirements. Some solvents may react with materials. Opt for stirrers that can withstand your lab's conditions. This ensures longevity and performance.

**Tips:** Always test the stirrer in a small-scale setup first. It helps identify potential issues without wasting time. Consider your mixing speed needs. A slow, consistent stir may be more effective than a fast, vigorous one. In the end, reflect on your lab's unique challenges. A well-chosen PTFE stirrer can make a significant difference.

When considering PTFE stirrers, it's essential to understand the various types available. Each type has unique applications tailored for specific laboratory needs. PTFE, known for its chemical resistance, is ideal for mixing highly corrosive substances. Different stirrer designs include fixed, adjustable, and magnetic options, each serving distinct functions. According to a recent industry report, around 45% of labs prefer magnetic stirrers for their simplicity and efficiency.

Fixed PTFE stirrers are sturdy and reliable for constant use. They often handle higher viscosity materials well. Adjustable stirrers, on the other hand, provide flexibility for varying viscosities. They are adaptable but need regular calibration to maintain accuracy. This adaptability can sometimes lead to inconsistencies if not monitored properly. Magnetic stirrers, while convenient, may require specific conditions to work effectively.

In practical applications, PTFE stirrers have become essential in pharmaceuticals and chemical research. Data indicates that 68% of lab technicians prioritized ease of cleaning and maintenance when selecting stirrers. While PTFE's non-stick quality promotes easier cleaning, wear and tear can occur over time. This may lead to contamination risks if not inspected regularly. Understanding these subtleties can significantly impact sterility and efficiency in lab operations.

This chart illustrates the different types of PTFE stirrers commonly used in laboratories and their respective application counts in various lab settings. The data shows that standard PTFE stirrers are the most widely employed, while immersion stirrers are less common.

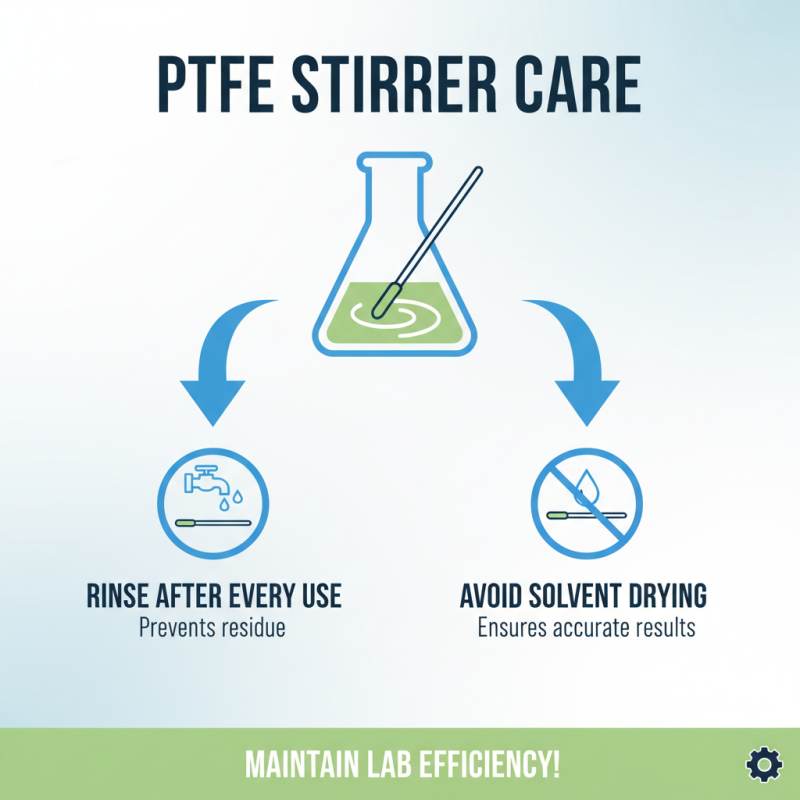

Maintaining PTFE stirrers is vital for lab efficiency. These stirrers resist chemicals well, but they need care. Rinse them after every use. This simple step prevents residue build-up. Even a small drop of solvent can impact results.

Use mild detergents when cleaning. Harsh chemicals may degrade the PTFE material. After washing, dry them completely. Storing a wet stirrer can lead to mold growth. A quick check of the stirrers for scratches or wear is advisable. Any damage can affect stirring performance.

While PTFE stirrers are durable, they aren't indestructible. Regular inspections can save time and prevent errors. Make a habit of reviewing their condition. This often-overlooked step can enhance lab productivity. Remember, a little care goes a long way.

When selecting a stirrer for laboratory applications, PTFE options stand out for several reasons. PTFE, or polytetrafluoroethylene, is renowned for its chemical resistance. According to a recent industry report, PTFE can resist over 95% of chemicals found in laboratories. This makes it a suitable choice for various experiments involving corrosive substances. Its durability allows for extended usage without wear, unlike many metal or plastic stirrers.

Comparing PTFE stirrers to other materials reveals notable differences. Metal stirrers may corrode when in contact with certain acids. This leads to wear and contamination of samples. In contrast, PTFE's inert nature ensures sample integrity. However, PTFE stirrers are less effective in high-viscosity liquids. They may struggle compared to specialized stirrers made from other materials. Interestingly, the market has reported a steady growth in PTFE stirrer usage, which can be attributed to increased awareness of chemical safety.

Consider the environment where these stirrers will be used. Heat resistance is another area where PTFE excels. It remains stable at high temperatures, unlike many plastics. Yet, attention is needed in applications involving extreme heat. Some users overlook the importance of cleaning protocols, which can affect performance. Ultimately, choosing the right stirrer requires examining specific lab needs while weighing the advantages and limitations of PTFE against other options.