In the realm of laboratory research and analysis, the selection of appropriate equipment plays a critical role in ensuring accurate and reliable results. Among such equipment, the PTFE centrifuge tube has garnered attention due to its exceptional properties, including high chemical resistance and thermal stability. According to a report by Grand View Research, the global market for centrifuge tubes is projected to reach $1.2 billion by 2027, with PTFE tubes expected to capture a significant share due to their suitability for handling aggressive chemicals and high-purity applications.

Selecting the right PTFE centrifuge tube involves considering factors such as the specific application, volume capacity, and compatibility with diverse solvents. This guide aims to equip laboratory professionals with essential insights into making an informed decision that aligns with their unique laboratory needs, ultimately enhancing their operational efficiency and experimental accuracy.

PTFE, or polytetrafluoroethylene, is a versatile material widely used in laboratory applications due to its unique properties. One of its most notable features is its exceptional chemical resistance. PTFE can withstand harsh solvents, acids, and bases, making it an ideal choice for centrifuge tubes used in diverse chemical and biological experiments. Additionally, PTFE is non-stick, which facilitates easy sample retrieval and minimizes contamination risks, ensuring the integrity of sensitive experiments.

Another significant advantage of PTFE tubes is their ability to endure high temperatures without degrading. This thermal stability means that PTFE centrifuge tubes can be used in various thermal applications, from freezing samples to high-temperature sterilization processes. Furthermore, PTFE exhibits low friction and excellent mechanical strength, which contributes to the durability of centrifuge tubes, enabling them to withstand the stresses of high-speed centrifugation. These properties collectively make PTFE an essential material for researchers aiming to achieve reliable and accurate results in their laboratory workflows.

| Property | Description | Benefits | Applications |

|---|---|---|---|

| Chemical Resistance | Outstanding resistance to a wide range of chemicals and solvents. | Minimizes contamination and extends tube life. | Suitable for chemical analysis and reaction setups. |

| Temperature Range | Operable within a temperature range of -200°C to 260°C. | Allows for use in extreme conditions. | Ideal for high-temperature and low-temperature applications. |

| Mechanical Strength | High tensile strength and resistance to mechanical stress. | Durable design reduces breakage. | Useful in centrifugation and other force-related applications. |

| Non-stick Surface | Smooth, non-adhesive inner surface. | Facilitates easy removal of samples. | Great for applications requiring sample purity and recovery. |

| Autoclavability | Can be sterilized in an autoclave without degrading. | Ensures sterility for sensitive experiments. | Recommended for microbiology and cell culture work. |

When selecting the appropriate PTFE centrifuge tube, it is crucial to first identify your specific laboratory requirements. Consider the nature of the samples you will be processing, as different applications may necessitate varying capacities and resistance levels. For instance, if you are working with corrosive chemicals or high-temperature samples, choosing a tube designed to withstand such conditions will ensure sample integrity and prolong the tube's lifespan.

Additionally, evaluate the compatibility of the centrifuge tubes with your existing laboratory equipment. This includes considering the size and type of your centrifuge rotor, as well as the desired speed and g-forces. Ensuring that the PTFE tubes fit properly in your centrifuge will enhance safety and efficiency during operation. You should also consider factors such as volume requirements and whether you need tubes with specific features like graduated markings for measuring liquid levels, which can further optimize your workflow.

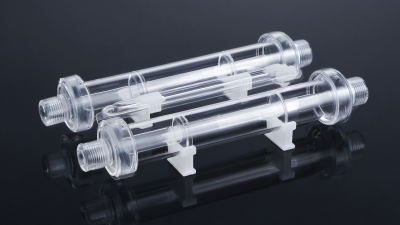

When selecting the appropriate PTFE centrifuge tube for your laboratory, it's essential to evaluate the size, capacity, and type tailored to your specific experimental requirements. PTFE tubes are available in various sizes, typically measured in milliliters (mL), and choosing the right size is crucial for maximizing centrifugation efficiency. Smaller tubes, often in the range of 1.5 mL to 15 mL, are ideal for routine applications with limited sample volumes, whereas larger tubes, such as 50 mL or more, cater to bulk samples or when higher capacities are necessary.

The capacity of the centrifuge tube should align with the anticipated sample volume while considering the need for appropriate centrifugation force. Overfilling a tube can lead to leakage or sample contamination, affecting results. Additionally, different types of PTFE centrifuge tubes, such as conical or flat bottom, may be better suited for specific applications. Conical tubes facilitate easy sedimentation and pelleting, while flat bottom tubes are beneficial for watching reactions or chromatographic separations. Careful consideration of these factors ensures optimal performance and reliability in laboratory procedures.

When selecting PTFE centrifuge tubes, the balance between cost and quality is crucial for laboratory efficiency and reliability. High-quality PTFE tubes are essential for various applications, including chemical resistance and minimal sample contamination. According to reports from industry experts, laboratory-grade PTFE tubes exhibit a tensile strength that significantly influences their durability under high-speed centrifugation. This tensile strength typically ranges from 20 to 40 MPa, suggesting that investing in higher-quality materials can lead to lower replacement costs over time, countering the initial expenditure.

Additionally, recent advancements in monitoring filament properties in laboratory environments provide relevant insights for selecting PTFE tubes. The integration of real-time measurements of parameters such as moisture content, roundness, and structural integrity enhances the assurance of quality in lab materials. An emphasis on quality control reduces the likelihood of defects, providing significant cost savings in the long run. By assessing both quantifiable quality metrics and initial investments, labs can make informed decisions that align with their operational requirements and budget constraints, ultimately ensuring optimal performance and reliability.

When selecting PTFE centrifuge tubes for laboratory needs, it is crucial to ensure compatibility with existing equipment and reagents. As the life sciences tools market is projected to grow from $152.45 billion in 2024 to $309.59 billion by 2031 at a compound annual growth rate (CAGR) of 10.65%, laboratories are increasingly seeking solutions that integrate seamlessly with their operational systems. The importance of durability and chemical resistance in PTFE centrifuge tubes cannot be overstated, as these attributes are essential for maintaining sample integrity across various applications, including molecular diagnostics and high-throughput sequencing.

Furthermore, with advancements in automated systems for slide staining and liquid handling, such as the automatic slide staining market expected to reach $50.15 million by 2032, the demand for tubes that can handle a wide range of reagents becomes critical. Ensuring that the chosen PTFE centrifuge tubes are compatible with specific buffers and solutions used in experiments will enhance reliability and accuracy. As laboratories strive to modernize and improve efficiency, selecting the right tools that meet compatibility standards will play a vital role in achieving successful outcomes in research and clinical applications.