Choosing the right PTFE stirrer bearing is crucial for optimal performance in various applications. According to industry reports, nearly 30% of operational failures in mixing equipment stem from inadequate bearing selection. This statistic highlights the importance of making informed choices when selecting PTFE stirrer bearings.

PTFE stirrer bearings offer unique advantages, including chemical resistance and low friction. These properties make them suitable for high-temperature processes and corrosive environments. In a recent study, 65% of engineers reported improved efficiency by using PTFE materials in their applications. However, not all PTFE stirrer bearings are created equal. Selecting the wrong specifications can lead to premature wear and inefficiencies.

Challenges arise in the selection process. It’s important to consider load capacity, temperature resistance, and compatibility with fluids. Each application has different demands. A mismatch can result in operational setbacks. Ultimately, the choice of a PTFE stirrer bearing can significantly affect performance, highlighting the need for careful evaluation.

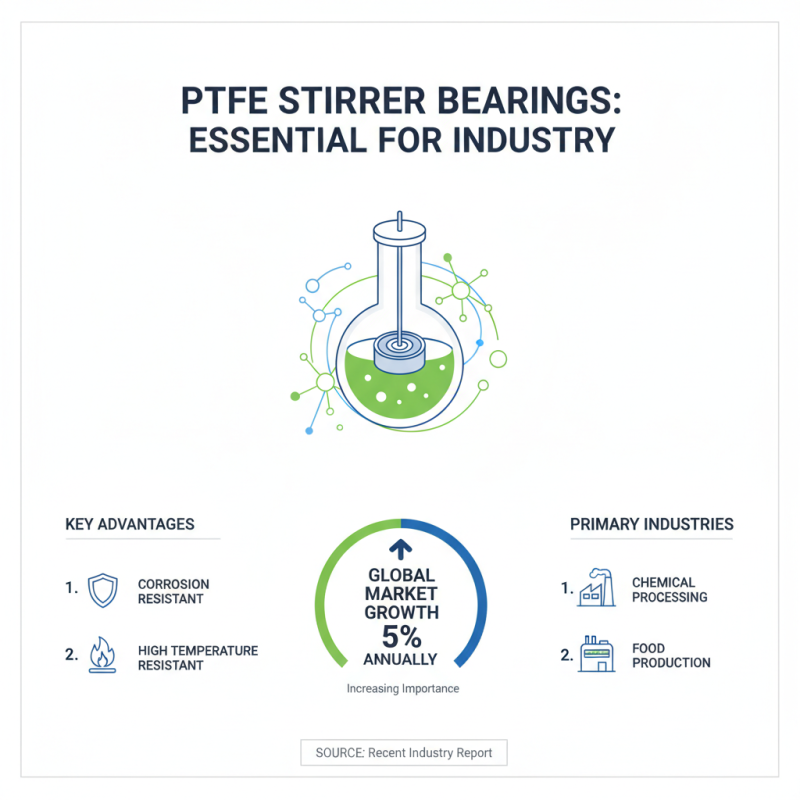

PTFE stirrer bearings play a crucial role in various industries, especially in chemical processing and food production. These bearings resist corrosion and high temperatures, which makes them ideal for harsh environments. According to a recent industry report, the global market for PTFE bearings is projected to grow by 5% annually, signaling their increasing importance.

Applications of PTFE stirrer bearings are diverse. In pharmaceutical manufacturing, they ensure the safe mixing of ingredients without contamination. Their self-lubricating properties reduce maintenance needs, resulting in cost savings. A leading study noted that equipment downtime can be reduced by up to 30% when using quality bearings. This reduction is significant for businesses aiming for efficiency.

However, not all PTFE stirrer bearings are created equal. Selecting the right one involves understanding specific needs. Some bearings may wear out faster in certain conditions. A miscalculation can lead to increased friction and even failure in critical operations. This highlights the importance of careful selection and ongoing evaluation in bearing choices. The right bearing can enhance performance significantly, while the wrong one can be a costly mistake.

Choosing the right PTFE stirrer bearing involves careful consideration of several factors. The operational environment is crucial. Assess temperature ranges, chemical compatibility, and pressure conditions. A well-matched bearing can enhance efficiency and longevity.

Material quality is another important factor. PTFE is known for its low friction and durability. However, not all PTFE is created equal. Look for high-grade options that ensure reliable performance. This will affect both performance and maintenance needs.

Tips:

- Check for specific certifications for your application.

- Don’t forget to assess installation ease. Complicated setups can lead to errors.

- Consider consulting with peers. Their experiences can provide valuable insights.

Reflect on your specific requirements before making a decision. The best choice is often the one that aligns perfectly with your specific needs, even if it takes more time to evaluate.

When selecting the right PTFE stirrer bearing, it's crucial to understand the options available. There are several types, each designed for specific applications. Some are suited for high temperatures, while others excel in chemical resistance. Consider the environment where the stirrer will operate. This knowledge helps narrow down your choices significantly.

Another key factor is the size and fit of the bearing. PTFE stirrer bearings come in various dimensions. A tight fit is essential for optimal performance. You might find a perfect size, yet it could underperform due to material weaknesses. Always check the specifications and assess the demands of your task. Balancing durability and functionality is often more challenging than it seems.

Pay attention to the installation process as well. Improper installation can lead to premature failure. Some users rush through this step, leading to regrets later. Taking time to ensure a proper setup can save time and resources. Even minor oversights can lead to significant issues down the line. Prioritize accuracy and safety in your selection, and you may lessen the chances of complications.

When selecting PTFE bearings, quality and performance are crucial. The material itself should be pure and free from contaminants. Many claim to provide high-quality PTFE, yet not all deliver. Always check for certifications and compliance with industry standards.

Evaluate the bearing's dimensions. A poorly sized bearing can lead to friction and wear. Performance can diminish quickly in such cases. Look for smooth surfaces; rough edges may indicate inferior manufacturing. Conduct visual inspections. Sometimes, the appearance can tell you a lot about the product's quality.

Testing under actual operating conditions is important. A bearing may look good but fail under stress. Pay attention to temperature resistance and load capacity. These factors can significantly impact performance. Remember, not every bearing performs as promised. Reflect on past experiences and learn from them. Seek feedback from others in your field. It can offer valuable insights that could guide your choice.

When choosing PTFE stirrer bearings, installation and maintenance are crucial. A proper setup ensures longevity and efficiency. Start by cleaning the installation area. Any debris can affect performance. Ensure that the stirrer shaft is properly aligned. Misalignment can lead to early wear.

**Tips for Installation:**

Use a clean workspace. Excess dirt can compromise the bearing. Apply lubricant before installation. This ensures a smooth start. Check for any signs of wear after the installation. Early detection is key.

For maintenance, keep an eye on performance. Listen for unusual noises. They can indicate potential issues. Regularly inspect the bearing for signs of wear. Replacing worn bearings promptly can save time and trouble. Simple actions can enhance performance significantly. Maintaining cleanliness around the stirrer can also prevent premature failure. Always strive for an optimal environment for the best results.

| Attribute | Details |

|---|---|

| Material | PTFE (Polytetrafluoroethylene) |

| Temperature Resistance | -200°C to 260°C |

| Chemical Compatibility | Resistant to most chemicals |

| Load Capacity | Up to 300 kg |

| Installation Method | Follow manufacturer's guidelines for secure fitting |

| Maintenance Tips | Regularly inspect for wear and tear, lubricate as needed |

| Common Applications | Chemical processing, food industry, pharmaceuticals |

| Lifespan | Typically 5-10 years with proper care |