Choosing the right stirring apparatus is crucial for efficient laboratory operations, particularly when it comes to using Magnets PTFE Stirrer Bars. These essential tools facilitate uniform mixing of solutions and samples, making them indispensable for various applications in chemistry and biology. As lab environments increasingly demand precision and reliability, understanding how to select the best PTFE stirrer bars equipped with magnets becomes vital for achieving optimal results.

In this comprehensive guide, we will explore key considerations for choosing the most suitable Magnets PTFE Stirrer Bars to meet your specific laboratory needs. Factors such as size, magnetic strength, chemical resistance, and stirrer bar shape will be discussed, ensuring you make an informed decision. Additionally, we will provide practical tips to enhance your stirring efficiency and prolong the lifespan of your equipment. By the end of this article, you will be well-equipped to select and utilize Magnets PTFE Stirrer Bars that not only meet your operational requirements but also elevate the quality of your experimental outcomes.

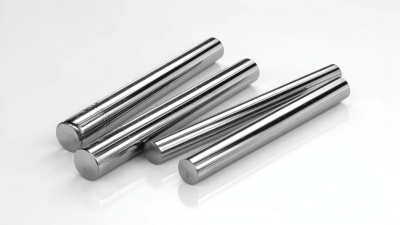

When selecting PTFE stirrer bars for laboratory applications, several critical factors must be considered to ensure optimal performance. One of the most important aspects is the stirrer bar's size and shape. According to a recent industry study, the efficiency of mixing is notably influenced by the length-to-diameter ratio of the stirrer bar. For most standard applications, a stirrer bar measuring between 10 to 30 mm in length is often recommended, as this range facilitates adequate vortex formation and ensures an even distribution of forces throughout the liquid medium.

Another factor to consider is the chemical compatibility of PTFE stirrer bars with the solvents used in your specific laboratory environment. PTFE, known for its exceptional inertness, is suitable for a wide range of harsh chemicals, including strong acids and bases. Research from the American Chemistry Society highlights that almost 90% of chemical reactions benefit from using PTFE stirrer bars due to their non-reactive nature, ensuring accurate results without contamination. Additionally, surface finish and magnetic strength must also be taken into account; a high-quality PTFE stirrer bar with a smooth surface enhances the mixing efficiency, while a strong magnet ensures robust stirring under varying viscosities.

When selecting PTFE stirrer bars for laboratory applications, evaluating performance metrics such as efficiency and speed of stirring action is crucial. The efficiency of a stirrer bar is determined by its ability to create a uniform mixture while minimizing turbulence. Factors such as the length and diameter of the stirrer bar, as well as its magnetic strength, directly influence its performance. Shorter stirrer bars may be suitable for small volumes but may not provide the same mixing efficiency as longer counterparts in larger containers.

Speed is another essential metric to consider. The optimal stirring speed can vary depending on the viscosity of the solution being mixed. Stirrer bars that can handle a wider range of speeds are more versatile and can adapt to different experimental conditions. Furthermore, the material properties of PTFE ensure chemical resistance and a lower friction coefficient, enhancing the stirrer's ability to maintain high speeds without overheating. By carefully assessing these performance metrics, laboratory professionals can select the best PTFE stirrer bars to meet their specific application needs.

| Stirrer Bar Type | Material | Length (cm) | Magnet Strength (Gauss) | Max Speed (rpm) | Stirring Efficiency (%) |

|---|---|---|---|---|---|

| Standard Stirrer | PTFE | 5 | 700 | 1200 | 85 |

| High-Viscosity Stirrer | PTFE | 7 | 800 | 900 | 90 |

| Micro Stirrer | PTFE | 3 | 600 | 1500 | 80 |

| Specialty Stirrer | PTFE | 10 | 750 | 1100 | 92 |

When selecting the best PTFE stirrer bars for laboratory applications, understanding the material composition is crucial, particularly the role of polytetrafluoroethylene (PTFE) in enhancing chemical resistance and durability. PTFE is renowned for its exceptional resistance to a wide variety of chemicals, making it an ideal choice for laboratories that handle corrosive substances. According to a report by the American Chemical Society, materials such as PTFE can withstand temperatures up to 260°C and maintain structural integrity in highly acidic or alkaline environments, which is vital for ensuring reliability during experiments.

In addition to chemical resistance, PTFE's low-friction properties allow for smooth stirring, reducing the risk of contamination and improving the efficiency of mixing processes. A study conducted by the Journal of Material Science found that PTFE stirrer bars not only enhance the longevity of laboratory equipment but also contribute to more reproducible results in experiments, as they minimize shear stress on sensitive solutions. This combination of durability and performance makes PTFE stirrer bars an indispensable tool in various scientific applications, from pharmaceuticals to environmental testing, solidifying their place as a fundamental component in laboratory settings.

When selecting PTFE stirrer bars for laboratory applications, size and shape variations are critical to achieving optimal mixing efficiency. According to a report by the American Chemical Society, effective stirring depends heavily on the geometry of the stirrer bar in relation to the vessel type. For instance, round stirrer bars are ideal for standard Erlenmeyer flasks, while oval or square bars offer improved performance in wider vessels, where a greater surface area contact is necessary to maintain a consistent vortex.

Furthermore, the length of the stirrer bar should correspond to the diameter of the vessel to ensure proper stirring action. Research indicates that a stirrer bar should ideally have a length that is approximately 2/3 the diameter of the vessel. In specific applications like high-viscosity liquids, an appropriately sized stirrer bar can significantly reduce mixing time and enhance homogeneity. By selecting the right dimensions and shape, researchers can achieve consistent results and improve the reproducibility of their experiments, thereby reinforcing the importance of tailored solutions in laboratory settings.

When selecting PTFE stirrer bars for laboratory applications, a cost-benefit analysis is crucial to ensure that quality and budget align. Recent market research indicates that high-quality PTFE stirrer bars can last up to three times longer than lower-cost alternatives, potentially saving laboratories significant amounts in replacement costs. The initial investment in durable equipment pays off through increased efficiency and reduced downtime, emphasizing the importance of making informed purchasing decisions.

Tips: Choose stirrer bars with high chemical resistance and thermal stability to maximize their lifespan and performance in various experiments. Additionally, consider the magnetic strength and size of the stirrer bars against your specific laboratory needs to avoid compromising on either quality or effectiveness.

Evaluating operational budgets against the total cost of ownership can clarify the financial impact of your choices. For example, studies show that over 60% of laboratory managers prioritize quality over budget when it comes to essential equipment like stirrer bars. This indicates a strong trend toward investing in superior products that enhance overall laboratory performance and reliability.