Choosing the right materials for your projects can significantly impact the overall performance and efficiency of your applications, especially when it comes to magnetic solutions. Among the various options available, PTFE coated magnetic materials have gained popularity due to their unique properties that blend the advantages of non-stick PTFE with the robust functionality of magnetic components. This combination not only enhances the usability of the magnetic solutions but also provides added resistance to chemicals and high temperatures, making them suitable for a wide range of environments.

In this guide, we will explore the essential considerations when selecting the best PTFE coated magnetic solutions for your specific needs. From understanding the different types of coatings and their respective benefits to evaluating the mechanical and thermal properties that affect performance, this comprehensive overview aims to equip you with the knowledge necessary to make informed decisions. Whether you are working on industrial applications or intricate design projects, utilizing PTFE coated magnetic materials can significantly enhance your outcomes and ensure long-lasting durability.

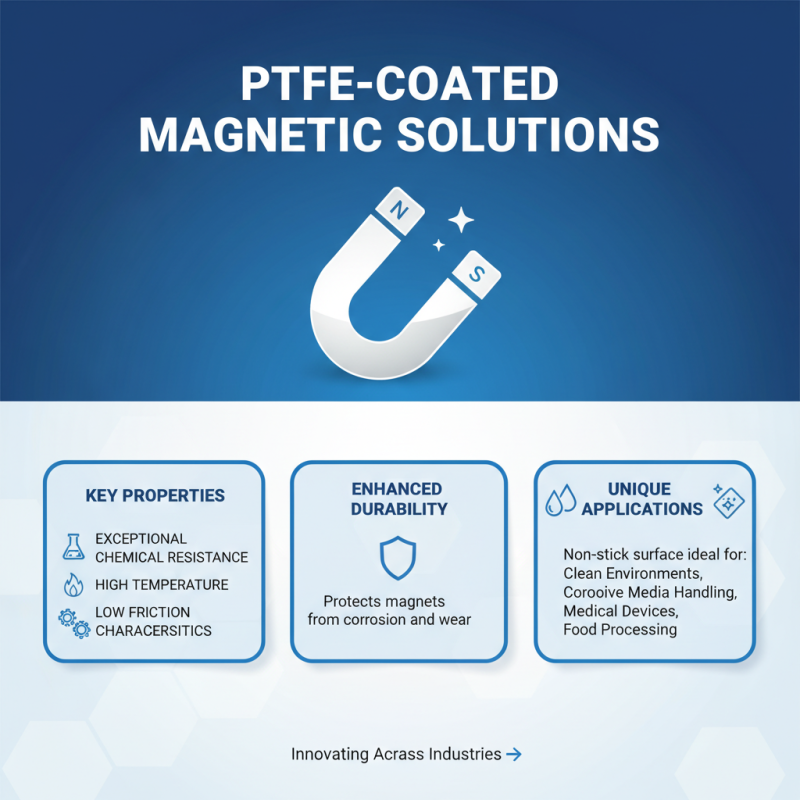

PTFE coated magnetic solutions have become increasingly popular across various industries due to their unique properties and applications. PTFE, or polytetrafluoroethylene, is recognized for its exceptional chemical resistance, high-temperature tolerance, and low friction characteristics. When combined with magnetic materials, PTFE coatings not only enhance the durability of magnets but also provide a non-stick surface, making them ideal for environments where cleanliness and resistance to corrosive substances are paramount.

These coated magnetic solutions are particularly useful in industries such as food processing, pharmaceuticals, and electronics. In food processing, for example, PTFE coated magnets can help maintain hygiene standards while preventing contamination during production. In pharmaceuticals, they facilitate the precise movement and positioning of equipment without the risk of corrosion. In the electronics sector, PTFE's insulating properties combined with the magnetic solutions can lead to more efficient and reliable designs in components that require both adhesion and resistance to environmental factors. Understanding the specific application needs of each project will guide the effective selection of the right PTFE coated magnetic solutions, ensuring optimal performance and longevity.

When selecting PTFE coated magnetic solutions for your projects, it's essential to consider several key factors that can affect performance and suitability. One important aspect is the operating temperature range. PTFE coatings can withstand high temperatures, making them ideal for applications in harsher environments. Always ensure that the magnetic solution you choose can maintain its performance under your specific temperature conditions.

Another crucial factor is the size and shape of the magnets. Depending on your application, you may need different sizes or configurations. Consider the space available and the strength required for your project. A well-designed magnet can provide better performance and efficiency, so carefully assess your project's needs before making a choice.

Tips:

1. Evaluate the chemical resistance of the PTFE coating, especially if your project involves exposure to aggressive substances.

2. Review the magnetic strength specifications to ensure they align with your project's requirements.

3. Don't overlook the installation process; some PTFE coated magnets may require specific handling or mounting techniques to achieve optimal results.

| Factor | Description | Importance Level |

|---|---|---|

| Temperature Resistance | Consider the operating temperature range where the magnets will be used. | High |

| Magnetic Strength | Evaluate the pull force and holding strength required for your application. | High |

| Size and Shape | Determine the dimensions and form factor suitable for your project requirements. | Medium |

| Coating Durability | Assess the PTFE coating's resistance to wear, chemicals, and moisture. | High |

| Application Environment | Consider the environmental factors like humidity, dust, and exposure to chemicals. | Medium |

| Cost | Evaluate the pricing options available while considering longevity and effectiveness. | High |

When selecting PTFE coated magnetic solutions, it’s essential to compare the various types available to ensure they meet your project requirements effectively. PTFE, or polytetrafluoroethylene, is renowned for its excellent non-stick properties and resistance to high temperatures, making it an ideal coating for magnetic products used in industrial and commercial applications. Key distinctions among these solutions arise from their differing magnetic strengths, durability, and temperature tolerances. For example, some options might offer higher magnetic pull forces, while others may focus on enhanced resistance to chemical exposure.

Another critical aspect to consider is the application environment. Certain PTFE coated magnetic solutions may be better suited for wet or corrosive conditions, where standard coatings might fail. Additionally, if the solution will be subjected to high-frequency magnetic fields, it’s important to choose a type specifically designed to maintain performance under such conditions. By thoroughly evaluating these factors and comparing the unique characteristics of each PTFE coated magnetic solution, project managers can make informed choices that will enhance the efficiency and longevity of their applications.

When selecting PTFE coated magnetic solutions for various projects, it's essential to evaluate their performance and durability to ensure optimal functionality. PTFE, or polytetrafluoroethylene, offers superior resistance to heat and chemical degradation, making it an excellent choice for applications in harsh environments. According to recent industry reports, magnets coated with PTFE can withstand temperatures up to 260°C without losing their magnetic properties, which is significantly higher than standard uncoated magnets. This remarkable heat resistance opens up a wide array of applications, particularly in industries such as aerospace, automotive, and chemical processing where environmental conditions can be extreme.

Moreover, the durability of PTFE coated magnets extends beyond thermal resilience. The coating provides excellent lubrication characteristics, reducing friction and wear, and thus extending the lifespan of the magnets. A study published in the Journal of Materials Science highlights that PTFE coated magnets demonstrated improved resistance to corrosion compared to their bare counterparts, showing less than 5% degradation after 1,000 hours in saline environments. This indicates that for projects requiring longevity and reliability, particularly where cleanliness and chemical exposure are concerns, PTFE coated magnets provide a significant advantage. Evaluating these performance metrics can help engineers and project managers make informed decisions for their specific needs.

When implementing PTFE coated magnetic solutions in your projects, it is essential to prioritize the compatibility of materials and the specific needs of your applications. Start by assessing the environmental conditions in which the magnetic solutions will operate. Factors like temperature, humidity, and exposure to chemicals can greatly influence the performance and longevity of PTFE coatings. A thorough understanding of these conditions will help you select coatings that provide optimal resistance and durability.

Additionally, consider the integration process of PTFE coated magnets within your project framework. Ensure you are using the appropriate adhesives or mechanical fastening methods that are compatible with PTFE. A smooth surface is critical for maximum adhesion, so surface preparation processes such as cleaning and roughening can be beneficial. Testing prototypes in real-life scenarios will also allow you to identify potential issues early on and make necessary adjustments to the design or materials used, ensuring effective implementation of your solutions.