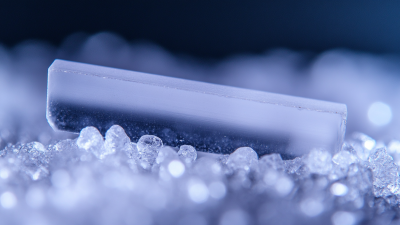

In the realm of laboratory experiments, efficiency and precision are essential for achieving reliable results. One of the critical components that significantly influences the efficacy of various procedures is the Lab PTFE Magnetic Stirrer Bar. This seemingly simple tool plays a pivotal role in mixing solutions uniformly and reducing the time required for achieving homogeneity in experimental setups. However, not all magnetic stirrer bars are created equal; the choice of material, size, and design can dramatically affect performance and experiment outcomes.

Selecting the appropriate Lab PTFE Magnetic Stirrer Bar ensures optimal stirring action, enhances reaction rates, and minimizes the risk of contamination. PTFE, or polytetrafluoroethylene, is renowned for its chemical resistance and low friction properties, making it an ideal material for use in diverse laboratory environments. By understanding the various types and specifications of magnetic stirrer bars available, researchers can better support their experimental goals and streamline workflows, ultimately leading to more efficient and reproducible results.

In conclusion, the right Lab PTFE Magnetic Stirrer Bar is not just an accessory; it is a crucial element that can significantly alter the efficiency and accuracy of laboratory experiments. As scientific inquiry continues to demand precision and speed, investing in the right tools will empower researchers to achieve their objectives more effectively.

In laboratory settings, the use of PTFE magnetic stirrer bars is pivotal for enhancing experiment efficiency. These stirrer bars, composed of polytetrafluoroethylene (PTFE), offer a non-stick surface that significantly reduces the risk of chemical contamination. This feature is particularly beneficial when conducting sensitive experiments where even a trace of impurity can compromise results. Their inert nature ensures compatibility with a wide range of solvents, making them ideal for diverse applications in chemical, biological, and pharmaceutical research.

Moreover, PTFE magnetic stirrer bars provide superior thermal resistance, allowing them to endure high-temperature conditions without deteriorating. This robustness not only increases the longevity of the stirrer bars but also reduces the frequency of replacements, leading to cost savings for laboratories. Additionally, their design facilitates efficient mixing of solutions, resulting in faster reaction times and improved reproducibility of experiments. By streamlining the mixing process and minimizing cross-contamination, PTFE magnetic stirrer bars are an essential tool for researchers striving for accuracy and efficiency in their work.

| Feature | Description | Benefit |

|---|---|---|

| Material | PTFE (Polytetrafluoroethylene) | Chemical resistance allows for use with strong acids and bases |

| Temperature Range | High temperature stability (up to 260°C) | Facilitates reactions at elevated temperatures without degradation |

| Magnetic Compatibility | Designed to be compatible with various magnetic stirrers | Ensures even mixing and reduces sedimentation in samples |

| Ease of Cleaning | Non-porous and smooth surface | Reduces contamination risk and improves throughput |

| Durability | Resistant to wear and tear | Long-term cost savings due to reduced replacement frequency |

The choice of lab equipment significantly impacts the efficiency and accuracy of scientific experiments. Specifically, using the right PTFE magnetic stirrer bar can enhance chemical resistance and improve experimental outcomes. PTFE, or polytetrafluoroethylene, is known for its exceptional resistance to various chemicals, making it a preferred material in laboratories for experiments involving aggressive solvents. Its inert nature ensures that reactions are not influenced by the stirrer bar, allowing researchers to achieve reliable and reproducible results.

Tips: When selecting a PTFE magnetic stirrer bar, consider its size and shape based on the volume and viscosity of your samples. A well-matched stirrer can provide uniform mixing, which is crucial for accurate experimental readings. Additionally, regular maintenance of the stirrer bar can prolong its life and maintain its effectiveness in your experiments.

The growing global demand for high-purity materials, such as PFA (perfluoroalkoxy), highlights the importance of using quality components in laboratory settings. The PFA market is projected to reach $300 million by 2033, demonstrating a robust growth rate driven by advancements in manufacturing and increased chemical applications. Therefore, investing in the right materials and equipment is essential for improving overall lab efficiency and output quality.

The efficiency of mixing in laboratory settings is critical for enhancing experimental outcomes, and the design of magnetic stirrer bars plays a pivotal role in this aspect. Recent studies in chemical engineering highlight how variations in stirrer designs, much like passive micromixer optimizations, can significantly influence mixing performance and reaction rates. For instance, the study on the effects of pillar array configuration on mixing efficiency demonstrates that specific geometrical arrangements can reduce pressure drops while ensuring effective homogeneity in reactions. This principle mirrors the importance of selecting the optimal PTFE magnetic stirrer bar design.

Furthermore, innovations in mixing technologies, including developments in single-use mixers, have shown that tailored designs not only streamline the mixing process but also promote better interaction between reactants. The adaptability of these systems parallels that of traditional stirrers, suggesting that advancements in their design could lead to enhanced catalyst effectiveness in applications such as chemical polyolefin recycling. The convergence of well-engineered stirring mechanisms with chemical processes underscores a foundational relationship where improved mixing fundamentally enhances experimental efficiency and product recovery rates across various applications.

When selecting a PTFE magnetic stirrer bar, several key performance metrics can significantly enhance experimental efficiency. One of the most critical metrics is the stirrer bar length-to-diameter ratio, which affects the stirring speed and efficiency of the mixing process. Research conducted by the American Chemical Society indicates that an optimal length-to-diameter ratio of 3:1 can maximize vortex formation, leading to better reagent mixing and reduced reaction times by approximately 30% in solutions with high viscosities.

Another essential factor is the magnetic strength of the stirrer bar, which should be calibrated to ensure adequate torque generation without slipping. Data from the Journal of Laboratory Automation suggests that stir bars with a minimum magnetic strength of 600 gauss provide consistent stirring even in more robust chemical environments. Higher magnetic strength enables the stirrer to maintain performance during the high-viscosity applications often seen in polymer and biochemical experiments, ultimately improving overall experimental accuracy and repeatability.

Additionally, the chemical compatibility of the PTFE material is paramount. Studies show that PTFE stirrer bars exhibit superior resistance to a wide range of solvents—including acids and bases—thereby prolonging their lifespan and reducing the frequency of replacements. According to industry reports, the longevity of PTFE stirrer bars can be three to five times greater than their non-PTFE counterparts, offering considerable cost savings in laboratory operations.

The future of lab equipment is witnessing significant advancements, particularly in stirrer bar technology. Innovations in materials and design are enhancing the efficiency and effectiveness of magnetic stirrer bars. One notable trend is the development of composite PTFE (polytetrafluoroethylene) materials that improve chemical resistance and reduce friction, resulting in smoother operation and longer lifespan. These enhancements not only contribute to higher experimental accuracy but also ensure that stirrer bars can handle a wider range of substances, including highly corrosive chemicals.

Furthermore, integrating smart technology into stirrer bars is revolutionizing laboratory practices. Smart stirrer bars equipped with sensors can provide real-time feedback on mixing efficiency, temperature, and reaction progress, allowing researchers to make adjustments on-the-fly. This level of precision and control is crucial for experiments that rely on exact conditions for successful outcomes. As laboratories continue to embrace these technological advancements, the overall efficiency and reliability of experimental processes are set to improve significantly.