In the world of laboratory mixing, the choice of a Magnetic PTFE Stir Bar is crucial. Dr. Emily Hart, a leading expert in chemical engineering, once said, “Selecting the right stir bar can revolutionize your mixing process.” This statement underscores the importance of making informed choices.

Magnetic PTFE stir bars come in various shapes and sizes. Each design serves unique applications. Consider the stirring needs of your specific experiments. A stir bar too small may underperform, while one that is too large could be inefficient. It’s essential to evaluate these aspects carefully.

Materials also play a critical role. PTFE is resistant to many chemicals, but durability might vary. Users should reflect on their specific requirements. Not all stir bars are made equal, and small variations can lead to larger issues in experimental outcomes. The right Magnetic PTFE Stir Bar can significantly impact results, making thoughtful selection paramount.

Magnetic PTFE stir bars are essential tools for various laboratory applications. They provide uniform mixing of solutions, which improves experimental results. The key feature of a magnetic PTFE stir bar is its chemical resistance. PTFE can handle corrosive substances that other materials cannot. This makes them ideal for use in chemical, biological, or pharmaceutical labs.

Another advantage is their convenience. Magnetic stir bars eliminate the need for mechanical stirring devices. They simplify the mixing process. Users benefit from reduced contamination risk since the stir bar does not touch the liquid directly. However, choosing the right size is vital. A stir bar that is too large or small can lead to inefficient mixing. It can also affect the accuracy of experiments.

When selecting a stir bar, consider the shape and length. The shape influences how well the bar spins in the solution. A poorly designed stir bar may create dead zones where mixing isn’t effective. Additionally, think about the application. Different experiments may require unique features. It’s essential to reflect on these aspects to make the best choice for your specific needs.

Choosing the right magnetic PTFE stir bar can enhance your lab’s efficiency. Different types suit various applications. For instance, standard octagonal stir bars work well for general mixing tasks in liquids. However, they may struggle with high-viscosity solutions.

For specific needs, consider using cornered stir bars. These are ideal for achieving better mixing in viscous substances. They provide more surface area contact, improving overall performance. Data shows that cornered designs can optimize mixing efficiency by up to 30%. Magnetic PTFE stir bars with varying lengths and diameters can also affect mixing effectiveness. A longer stir bar may reach deeper vessels, but it could be harder to remove.

Revisiting selection criteria is essential. Some labs overlook the impact of stir bar geometry on performance. A round bar may not mix effectively in all scenarios. Mixing speed and container shape also play significant roles. An unsuitable choice may lead to inadequate mixing, affecting experimental outcomes. Observing these factors closely can help in selecting the most effective stir bar for specific applications.

| Type of Stir Bar | Length (cm) | Recommended Use | Max Volume (L) | Heat Resistance (°C) |

|---|---|---|---|---|

| Standard PTFE Stir Bar | 5 | General Mixing | 1 | 200 |

| Extra-Long PTFE Stir Bar | 10 | For Large Volumes | 4 | 200 |

| Mini PTFE Stir Bar | 3 | Small Scale Mixing | 0.5 | 200 |

| High-Viscosity PTFE Stir Bar | 7 | High Viscosity Liquids | 2 | 200 |

| Magnetic PTFE Coated Stir Bar | 5 | Chemical Applications | 1.5 | 150 |

When selecting a magnetic PTFE stir bar, various factors come into play. The size of the stir bar is crucial. It should fit well within your vessel, maximizing stirring efficiency while minimizing dead zones. A report from the Analytical Chemistry Journal mentions that the diameter of the stir bar can significantly impact mixing time and homogeneity. A well-sized stir bar can reduce mixing time by up to 30%.

The material composition also matters. PTFE is favored for its chemical resistance and non-stick properties. However, not all PTFE stir bars are the same. Some are designed for high-temperature applications, while others may not withstand certain solvents. According to recent industry studies, using the incorrect PTFE type can lead to decreased durability and performance.

Consider the magnetic strength of the stir bar. A stronger magnet provides better stability during stirring. This is particularly important in viscous solutions, where a weak magnet might cause the stir bar to lose its grip. Yet, oversizing the magnetic strength can lead to friction or damage to the stir bar. Finding a balance is essential and often requires trial and error. Experimenting with different types can highlight the nuances of your specific application.

Maintaining your magnetic PTFE stir bars is essential for longevity and efficient performance. Start by ensuring that each stir bar is thoroughly cleaned after every use. Residue can build up and affect stirring efficiency. Use warm soapy water and a soft brush for delicate scrubbing. Rinse well and dry completely before storage.

Store stir bars in a designated container to prevent damage. Avoid mixing them with other lab equipment, as scratches can reduce their effectiveness. Pay attention to signs of wear. If you notice chips or cracks, it may be time to replace your stir bars. Keeping an eye on their condition can save you from unexpected failures later.

Consider the working conditions when using stir bars. Harsh chemicals can degrade their material, leading to performance issues. A short test run can help identify if your stir bar is functioning optimally. Be proactive in spotting irregular behavior. These small details matter greatly when conducting experiments, so take your time to observe and reflect on their performance.

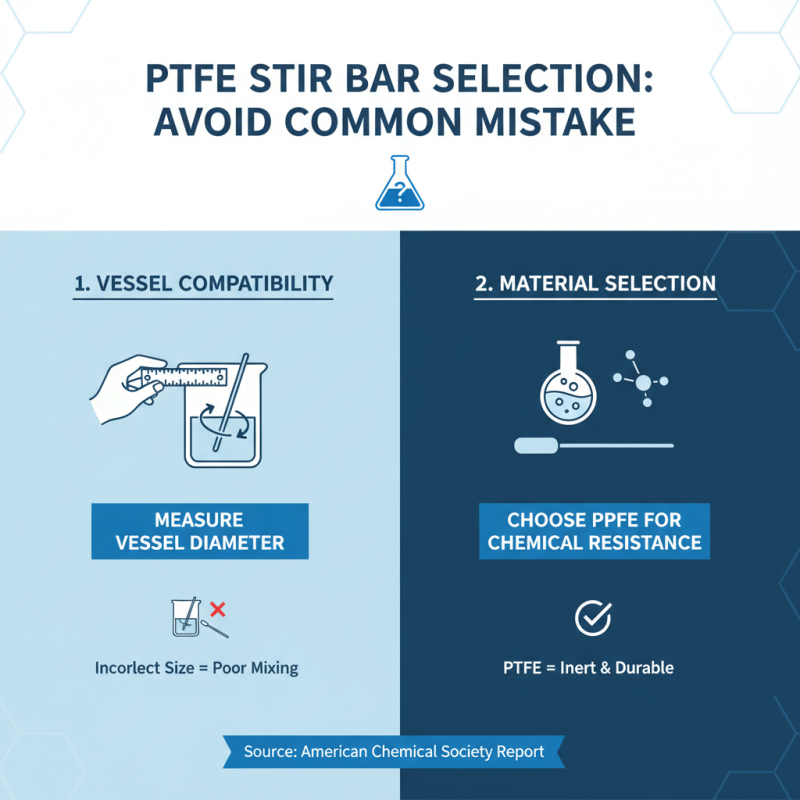

When selecting a magnetic PTFE stir bar, many overlook common mistakes. First, ensure compatibility with your vessel. Not all stir bars fit every beaker or flask. A report from the American Chemical Society noted that improper sizing can lead to inefficient mixing outcomes. It’s essential to measure your vessel's diameter accurately to avoid stirring issues.

Another mistake is ignoring the PTFE quality. The purity of PTFE affects the stir bar's performance and longevity. Some users choose lower-quality options without understanding the potential risks. Low-grade PTFE might degrade under high temperatures or chemical exposure, leading to contamination.

**Tip:** Check for reports or certifications that verify PTFE quality. High-grade materials result in better performance.

Lastly, consider the magnetic strength. A weak magnet can cause the stir bar to decouple, disrupting your mixing process. Research shows that a stronger magnet significantly improves stability and efficiency. Users often underestimate how vital this feature is to successful experiments.

**Tip:** Opt for stir bars with a strong magnetic core, especially for high-viscosity solutions.