Choosing the right PTFE coated magnetic stir bar can significantly impact laboratory outcomes. According to a report by Market Research Future, the global demand for magnetic stirrers and accessories is projected to grow by over 5% annually. This growth highlights the importance of selecting high-quality components like PTFE coated magnetic stir bars.

Dr. Emily Thompson, a leading expert in laboratory equipment, once stated, "The effectiveness of your magnetic stirring process starts with the right stir bar." It emphasizes the need for precision in selection. PTFE coated magnetic stir bars offer superior chemical resistance and durability. However, not all stir bars are created equal. Variations in size, shape, and coating thickness can lead to differences in performance.

When considering a purchase, buyers should assess the intended application. Will the stir bar be used for harsh chemicals or gentle mixtures? This decision can influence the choice of PTFE coated magnetic stir bar. Attention to these details ensures optimal performance and longevity in experimental procedures.

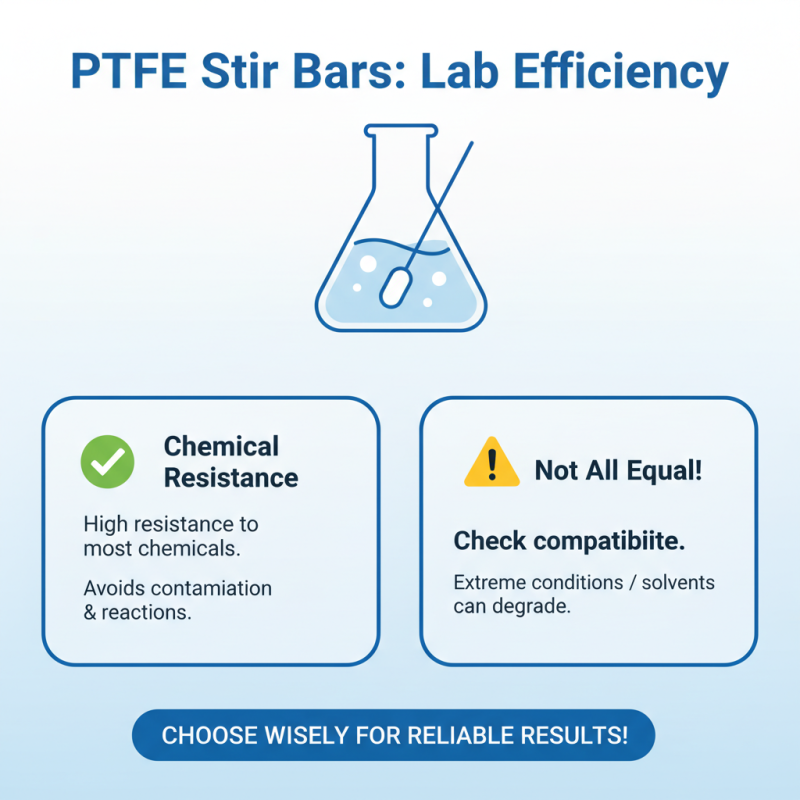

PTFE coated magnetic stir bars are essential in many laboratory applications. They provide excellent chemical resistance, allowing them to handle various solvents and acids without degradation. The smooth surface of these stir bars reduces friction, leading to efficient mixing. Their unique properties make them ideal for sensitive experiments.

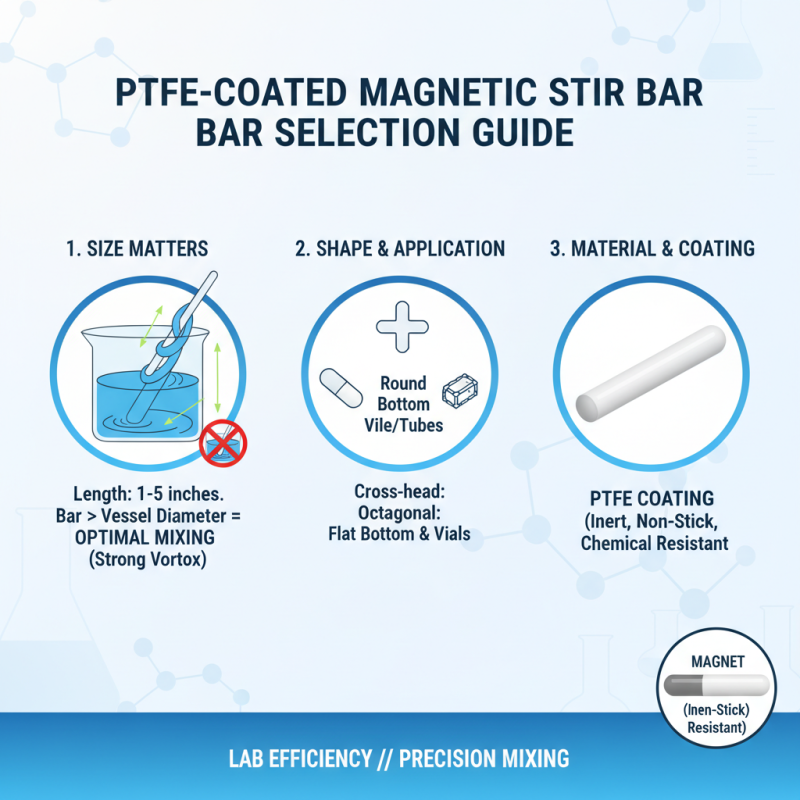

When choosing a PTFE coated stir bar, consider its size and shape. A longer stir bar may provide better stirring in larger containers, but it can also be more difficult to control. Shorter stir bars fit easily in smaller vessels but might not produce as much turbulence. It's vital to match the stir bar's dimensions with the container for optimal mixing.

**Tips:** Always check compatibility with your solutions. Not all coatings are equal. Sometimes, users overlook the importance of consistent rotation speed. A stir bar that’s too heavy may not work well in a delicate solution. Experimentation often leads to better outcomes. Do not hesitate to adjust your technique based on your initial results. Your approach today can always improve tomorrow.

When selecting a PTFE coated magnetic stir bar, several key factors are crucial. First, consider the size of the stir bar. The typical length ranges from 1 to 5 inches. According to industry data, a bar longer than the vessel’s diameter often provides optimal mixing. If it’s too short, it might not create effective vortexes.

Next, evaluate the temperature resistance. PTFE can withstand temperatures up to 260°C. This characteristic makes it suitable for many applications. However, not every PTFE bar can handle rapid temperature changes. A significant concern reported in laboratory studies shows that improper thermal cycling can shorten a stir bar’s lifespan.

Chemical resistance is another important factor. PTFE is known for its high inertness. Yet, when working with aggressive solvents or bases, some PTFE coatings may degrade. It's essential to verify compatibility based on specific solvents used. An often overlooked factor is the magnetic strength of the stirrer. Data indicates that a stronger magnetic force leads to better agitation. Weak magnetic stir bars can result in incomplete mixing, requiring longer processing times.

When selecting a PTFE coated magnetic stir bar, size and shape are crucial for performance. The diameter of the stir bar impacts the volume of liquid it can handle. A larger bar can stir more efficiently in a bigger container. However, if the bar is too large, it may not fit easily into narrow necks of certain flasks.

Shape also plays a role. Stir bars can be cylindrical or have a classic "fishing" shape. The latter often provides better agitation in a variety of liquids. It is essential to think about the type of solution being stirred. High-viscosity liquids need a specially designed stir bar. Many users overlook this and end up with poor results.

Many users experiment with different combinations. Some find that a simple cylindrical shape works best for standard applications. Others prefer the more specialized shape for optimal mixing. It's a common mistake to assume one size fits all. Understanding your specific needs can lead to better outcomes. However, there might be times when even careful planning doesn't yield the expected results. Adapting to these experiences is key for future success.

| Size (Length x Diameter) | Shape | Recommended Volume (L) | Magnetic Strength (G) | Common Applications |

|---|---|---|---|---|

| 5 cm x 0.6 cm | Straight | 1 - 2 L | 1000 | General Stirring |

| 7 cm x 0.8 cm | Straight | 2 - 5 L | 1200 | Chemical Mixing |

| 10 cm x 1 cm | Straight | 5 - 10 L | 1500 | Biological Samples |

| 5 cm x 0.6 cm | Curved | 1 - 2 L | 950 | Small Volume Stirring |

| 10 cm x 1.5 cm | Curved | 5 - 10 L | 1600 | Viscous Solutions |

Choosing the right PTFE coated magnetic stir bar is crucial for lab efficiency. One key factor to consider is the chemical resistance of the PTFE coating. PTFE is known for its high resistance to a wide variety of chemicals, which is essential for avoiding reactions that could compromise your experiments. However, not all PTFE coatings are created equal. Some may degrade under extreme conditions or with certain solvents.

Tips: Always verify the specifications of the PTFE coating you are considering. Look for detailed chemical resistance charts. These can guide you in selecting the right stir bar for your specific applications. Keep in mind the temperature limits of the coating.

Durability is another important aspect. Over time, the PTFE coating can wear down due to mechanical abrasion or prolonged exposure to harsh solvents. If the coating begins to peel or crack, it may contaminate your samples. Regularly inspect your stir bars for any signs of wear and tear.

Tips: When purchasing, consider the supplier’s return policy. If the product doesn’t meet your expectations, you should have options. Also, think about the environment where you’ll use the stir bar. This includes the temperature and the types of chemicals involved. It's an often-overlooked aspect that can lead to unexpected failures.

When selecting a PTFE coated magnetic stir bar, it’s essential to weigh cost against quality. PTFE stir bars can range from a few dollars to over fifty. A recent industry report indicated that high-quality stir bars improve efficiency and reduce downtime. This is crucial for labs aiming for consistent results. Investing in a reliable stir bar may seem costly upfront, but often leads to better outcomes and long-term savings.

Tip: Look for stir bars that have been tested for durability. Some cheaper options may wear out quickly, leading to frequent replacements. User reviews can provide insights on product longevity.

Many institutions rely on PTFE stir bars for their chemical stability and non-reactivity. However, not all products are created equal. Some low-cost options might use inferior materials, resulting in contamination. This internal conflict between cost and reliability can create challenges for labs. Identifying value involves considering compatibility with substances and overall performance over time.

Tip: Conduct small-scale tests when evaluating new stir bars. This approach allows you to observe performance without committing to larger quantities. Keep an eye on stir speed and consistency—it can reveal much about quality.