When it comes to laboratory work, precision and reliability are paramount. One essential piece of equipment that plays a critical role in achieving accurate measurements is the Ptfe volumetric flask. Known for its exceptional chemical resistance and durability, this type of flask is ideal for a variety of laboratory applications, ranging from sample preparation to solution dilution. However, with several options available on the market, selecting the right Ptfe volumetric flask to meet your specific laboratory needs can be a daunting task.

To make an informed choice, it is crucial to understand the unique properties of Ptfe and how they cater to different laboratory requirements. Factors such as the flask's capacity, tolerances, and features like graduation marks must be considered to ensure optimal performance in your experiments. Additionally, determining the compatibility of the Ptfe volumetric flask with the substances you plan to use will help in maintaining the integrity of your samples and achieving reliable results. By taking the time to evaluate these criteria, laboratory professionals can enhance their workflow efficiency and ensure the utmost accuracy in their measurements.

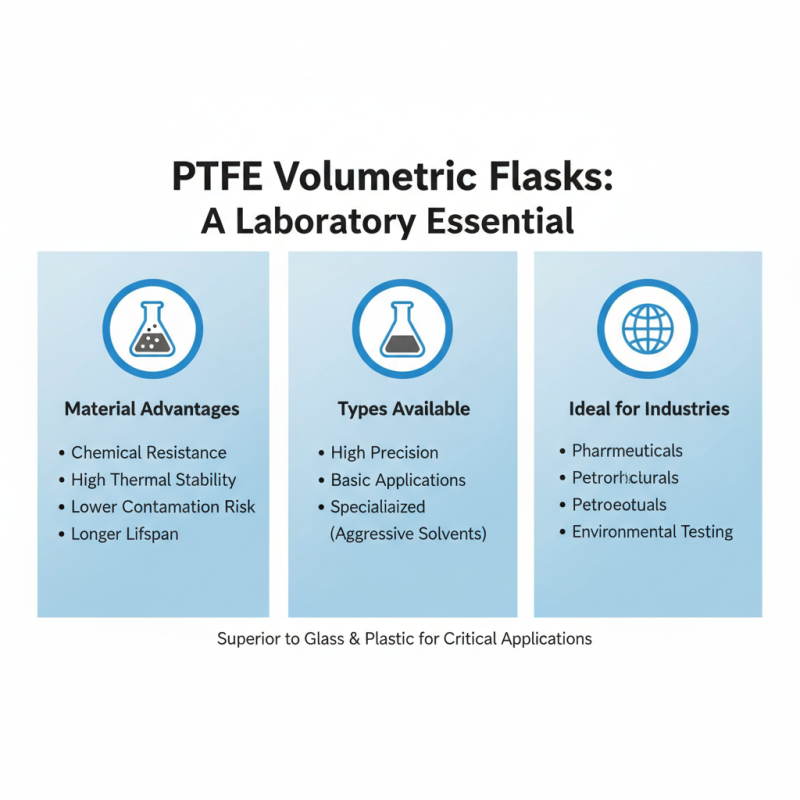

When selecting the appropriate PTFE volumetric flask for your laboratory, understanding the unique properties of PTFE (Polytetrafluoroethylene) is essential. PTFE is renowned for its exceptional chemical resistance, making it an ideal choice for laboratories that handle aggressive solvents and corrosive chemicals. Its non-reactive nature ensures that it will not leach any contaminants into samples, providing accurate and reliable measurements, which is critical in any scientific experimentation.

Additionally, PTFE has a high thermal stability, allowing it to withstand a broad temperature range without deforming or degrading. This property is particularly important in laboratories where flasks may be subjected to temperature fluctuations during various processes, such as heating or cooling. Furthermore, PTFE's low friction coefficient makes it easy to clean and maintain, reducing the risk of cross-contamination between experiments. Understanding these properties will aid in making an informed decision when choosing the right volumetric flask for specific laboratory needs.

When selecting the right PTFE volumetric flask for your laboratory, it is crucial to first identify your specific application requirements. Different experiments may necessitate varying levels of precision, volume capacity, and resistance to chemicals. For instance, if your laboratory work involves strong acids or bases, you’ll need a flask that not only provides precise volume markings but also withstands chemical degradation. The material’s compatibility with your substances will significantly determine how effectively the flask performs and maintains its integrity throughout its use.

Additionally, consider the temperature range your applications might reach. Some experiments involve heating elements or processes that can affect flask materials differently. PTFE is known for its excellent thermal stability, but variations in thickness and design can impact how well a flask handles unexpected temperature shifts. Furthermore, the size and shape of the flask can influence mixing and storage capabilities, thus affecting overall efficiency in your laboratory workflow. By assessing these specific requirements, you can make a more informed decision, ensuring that the PTFE volumetric flask you choose will adequately support your laboratory’s needs while guaranteeing the highest standards of safety and accuracy.

When selecting the right PTFE volumetric flask for your laboratory needs, considering the various types available is essential. PTFE (Polytetrafluoroethylene) is a valuable material in laboratories, known for its chemical resistance and high thermal stability. There are several types of PTFE volumetric flasks, including those designed for high precision, basic applications, and specialized uses such as those that handle aggressive solvents. According to industry reports, PTFE flasks offer a lower risk of contamination and longer lifespan compared to glass or plastic alternatives, making them suitable for a wide range of applications in pharmaceuticals, petrochemicals, and environmental testing.

When evaluating PTFE volumetric flasks, consider the capacity and the calibration accuracy. Standard capacities range from 25 mL to 2000 mL, and it’s crucial to select a flask that meets the specific measurement requirements of your experiments. Furthermore, look for flasks with ASTM E287 or ISO 1042 compliance, as these certifications ensure accuracy and reliability in measurements.

**Tips:** Prioritize purchasing from reputable suppliers that provide detailed specifications, including tolerance levels and calibration methods. Always verify if the flask’s design suits your particular application; for example, flasks used for corrosive substances should have features that minimize exposure to reactive chemicals. Additionally, consider flasks with secure sealing mechanisms to prevent spills or contamination in volatile environments.

When selecting a PTFE volumetric flask for laboratory applications, there are several critical factors to consider. First and foremost is the chemical compatibility of PTFE with the substances being measured. PTFE, known for its exceptional resistance to a wide range of chemicals, including strong acids and bases, makes it an ideal choice for laboratories dealing with aggressive reagents. According to industry reports, approximately 30% of lab accidents involving glassware are due to chemical reactions, highlighting the importance of selecting materials that can withstand potential hazards.

Another essential factor is the accuracy and precision requirements of your measurements. PTFE volumetric flasks provide high resistance to thermal expansion, ensuring that their volume remains stable across various temperatures. Studies indicate that volumetric flasks made from PTFE can achieve a volumetric accuracy of ±0.5%, which is crucial for laboratories that demand strict compliance with scientific standards. Furthermore, consider the specific volume size that meets your experimental needs, as PTFE flasks are available in various capacities, allowing for tailored solutions depending on the scale of your experiments.

Lastly, ease of cleaning and maintenance is a significant consideration. PTFE's non-stick surface minimizes residue buildup, facilitating efficient cleaning processes, which can enhance laboratory productivity. Research shows that laboratories spending less time on maintenance can increase their overall throughput by nearly 20%, making the choice of a PTFE volumetric flask not just a matter of compatibility and precision, but also of operational efficiency.

| Key Factor | Description | Recommended Specifications |

|---|---|---|

| Volume Capacity | Choose based on the volume of solutions you typically prepare. | 50 ml, 100 ml, 250 ml, 500 ml, 1000 ml |

| Material Quality | Ensure the PTFE is of high quality for durability and chemical resistance. | Virgin PTFE or similar grade |

| Neck Design | Consider the design of the neck for ease of use and sealing. | Wide neck or tapered, with appropriate stopper options |

| Calibration | Look for flasks with accurate calibration for precise measurements. | Class A calibration or better |

| Price | Evaluate your budget for laboratory equipment while considering quality. | $50 - $300 depending on capacity and features |

Maintaining the integrity and longevity of PTFE volumetric flasks is essential for any laboratory, particularly due to their unique chemical resistance properties. To ensure optimal performance, laboratories should adhere to specific maintenance and care guidelines. Regular cleaning is crucial; residues left from previous experiments can affect the accuracy of subsequent measurements. A study published in the "Journal of Laboratory Automation" highlighted that residual contaminants can lead to inaccuracies in volumetric measurements, with deviations up to 5% in sensitive applications. Therefore, it’s recommended to clean PTFE flasks with distilled water and a mild detergent, followed by thorough rinsing to remove any traces of cleaning agents.

Additionally, proper storage plays a significant role in the longevity of PTFE volumetric flasks. They should be stored upright in a stable environment, away from extreme temperatures and direct sunlight, which can alter their structural integrity. According to the International Standards Organization (ISO), improper storage conditions can reduce the lifespan of volumetric glassware, including PTFE variants, by nearly 20%. By implementing these maintenance strategies, laboratories can ensure that their PTFE volumetric flasks remain reliable tools for precise measurements, ultimately enhancing their experimental outcomes.