Selecting the right Ptfe crucible is crucial for maximizing efficiency and accuracy in laboratory applications, particularly in chemical analysis and material synthesis. According to a recent report by MarketsandMarkets, the global laboratory crucible market is projected to reach USD 1.2 billion by 2025, driven by the rising demand for durable and chemically resistant materials in research and development. Ptfe, or polytetrafluoroethylene, stands out due to its exceptional thermal stability and resistance to a wide range of chemicals, making it an ideal choice for high-performance laboratory environments. As researchers and scientists seek optimal solutions for their specific requirements, understanding the key factors involved in choosing the best Ptfe crucible will be pivotal in enhancing laboratory workflows and achieving reliable results.

When selecting the best PTFE crucible for your laboratory needs, it's essential to understand the key characteristics and benefits that make PTFE (Polytetrafluoroethylene) an outstanding material choice. PTFE crucibles are renowned for their exceptional chemical resistance, making them ideal for handling a wide range of solvents and reactive substances without risk of contamination. This property is particularly valuable in experimental settings where purity and accuracy are paramount.

Moreover, PTFE's high thermal stability allows it to retain its structural integrity even under extreme temperatures, thus ensuring reliable performance. These crucibles also boast excellent non-stick properties, facilitating easy removal of samples and minimal residue left behind. Innovative applications of PTFE, seen in recent advancements such as the development of ultra-filtration membranes for rural water supply systems, highlight its versatility and adaptability across various fields. As laboratories continue to pursue high-performance materials, PTFE crucibles emerge as a critical tool for enhancing efficiency and ensuring quality in research and experimentation.

When selecting a PTFE crucible for laboratory applications, several critical factors must be considered to ensure optimal performance. Firstly, temperature resistance is paramount, as PTFE crucibles can typically withstand temperatures up to 260°C. According to a study by the American Chemical Society, selecting materials that maintain structural integrity under high temperatures can significantly enhance accuracy in analytical processes, particularly in applications involving corrosive substances.

Another essential factor is the size and shape of the crucible, which should align with the specific needs of your experiments. A report by LabCompare indicates that the demand for various crucible sizes has risen by 25% over the past three years, highlighting how tailored solutions can improve sample handling and minimize contamination risks. Additionally, the chemical compatibility of the crucible with various substances is crucial, as PTFE is known for its excellent resistance to acids and bases, making it suitable for a diverse range of applications in chemical analysis and material synthesis. By carefully evaluating these factors, laboratories can choose the best PTFE crucible, ensuring reliability and precision in their work.

| Factor | Description | Consideration |

|---|---|---|

| Material Quality | Ensure the PTFE is virgin and free from fillers. | Higher purity generally equates to better performance. |

| Size and Capacity | Choose based on the volume of samples you are handling. | Consider both the dimensions and overall capacity. |

| Temperature Resistance | Check the temperature limits for the material used. | Ensure it meets the needs of your experimental procedures. |

| Chemical Resistance | Evaluate how the material reacts with various chemicals. | Choose a crucible that withstands the chemicals used in your tests. |

| Cost | Assess the price in relation to the crucible's features and quality. | Balance your budget with necessary specifications. |

| Ease of Cleaning | Choose a design that is easy to clean and maintain. | Minimize downtime between experiments with easier-to-clean options. |

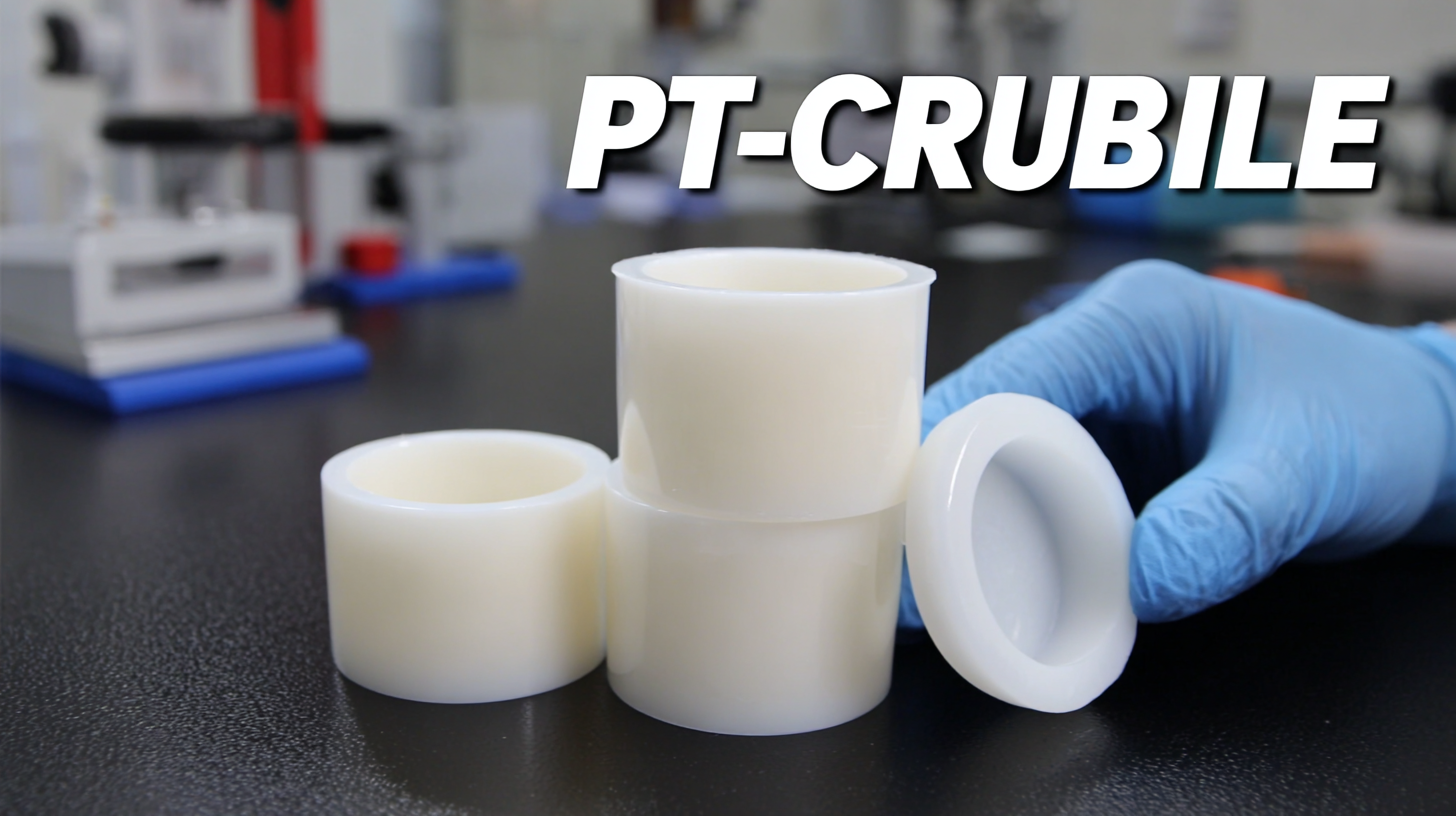

When selecting the best PTFE crucible for your laboratory needs, it's essential to consider the various types available and their specific applications. PTFE, known for its non-stick properties and high thermal resistance, comes in different forms, each suitable for distinct experiments. For instance, some crucibles are designed for high-temperature applications, while others may be more appropriate for chemical resistance when working with reactive substances. Understanding the materials you plan to work with will significantly influence your choice.

Additionally, it's important to compare the features of each PTFE crucible to ensure you select one that aligns with your laboratory processes. Some crucibles may have a thicker wall for enhanced durability, while others might be lighter and easier to handle. Consider how these factors will impact your workflow and experiment results. Just as selecting the right steel for a knife blade requires knowledge of different metal properties, choosing the ideal PTFE crucible necessitates an understanding of the unique characteristics offered by various models in order to optimize your lab's efficiency and effectiveness.

Maintaining PTFE crucibles is essential for ensuring longevity and optimal performance in the laboratory. The unique properties of PTFE, including its high resistance to chemicals and thermal stability, make it a popular choice for various applications. To prolong the life of your PTFE crucibles, it is crucial to handle them with care. Avoid exposing these crucibles to sudden temperature changes to prevent thermal shock, which could damage their structure. Additionally, use appropriate utensils, like non-metallic spatulas, to avoid scratching the surface.

Cleaning your PTFE crucibles regularly is another key aspect of maintenance. After each use, rinse them with warm water and mild, non-abrasive detergents. For stubborn residues, a soft cloth or sponge can help without damaging the crucible's integrity. Avoid using harsh chemicals or abrasive tools to prevent degradation of the PTFE material. Proper storage is equally important; store crucibles in a clean, dry environment, away from direct sunlight and extreme temperatures, to maintain their quality and performance over time.

When selecting a PTFE crucible for your laboratory needs, it's essential to stay informed about the latest technological trends and innovations in PTFE materials. The global market for PTFE coatings is expected to reach USD 20.62 billion by 2033, with a compound annual growth rate (CAGR) of 5.15%. This growth reflects not only the rising demand for high-performance materials but also advancements in manufacturing techniques that enhance the durability and functionality of PTFE products.

As you evaluate your options, consider the emerging trends in PTFE crucible technology. Innovations in surface treatments and composite materials are increasingly allowing for improved thermal stability and resistance to various chemicals. This can significantly elevate the performance of your laboratory experiments.

**Tips**: When choosing a PTFE crucible, ensure to check the temperature and chemical resistance specifications to fit your experimental needs. Additionally, look for trusted suppliers who offer detailed product insights and certifications that assure quality and performance. Opting for crucibles with enhanced features such as non-stick surfaces can also simplify clean-up and maintenance, making your lab work more efficient.