In today's industrial landscape, the selection of the right sealing solutions is crucial for operational efficiency and equipment longevity. Among various materials, PTFE sealing gaskets have gained significant prominence due to their exceptional chemical resistance and thermal stability. According to a recent market analysis report by Research and Markets, the global PTFE gasket market is expected to grow at a CAGR of 5.4% from 2021 to 2026, driven by the increasing demand for durable sealing materials in industries such as oil and gas, chemical processing, and pharmaceuticals. This guide aims to elucidate the factors one should consider when choosing the right PTFE sealing gasket to meet specific requirements, ensuring optimal performance and reliability in demanding applications.

PTFE sealing gaskets have quickly gained popularity in various industrial applications due to their unique properties and significant benefits. Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer known for its exceptional chemical resistance, making these gaskets an ideal choice for sealing in environments where corrosive substances are present. The ability of PTFE to withstand high temperatures and pressures further enhances its performance, ensuring a reliable and durable seal in critical applications.

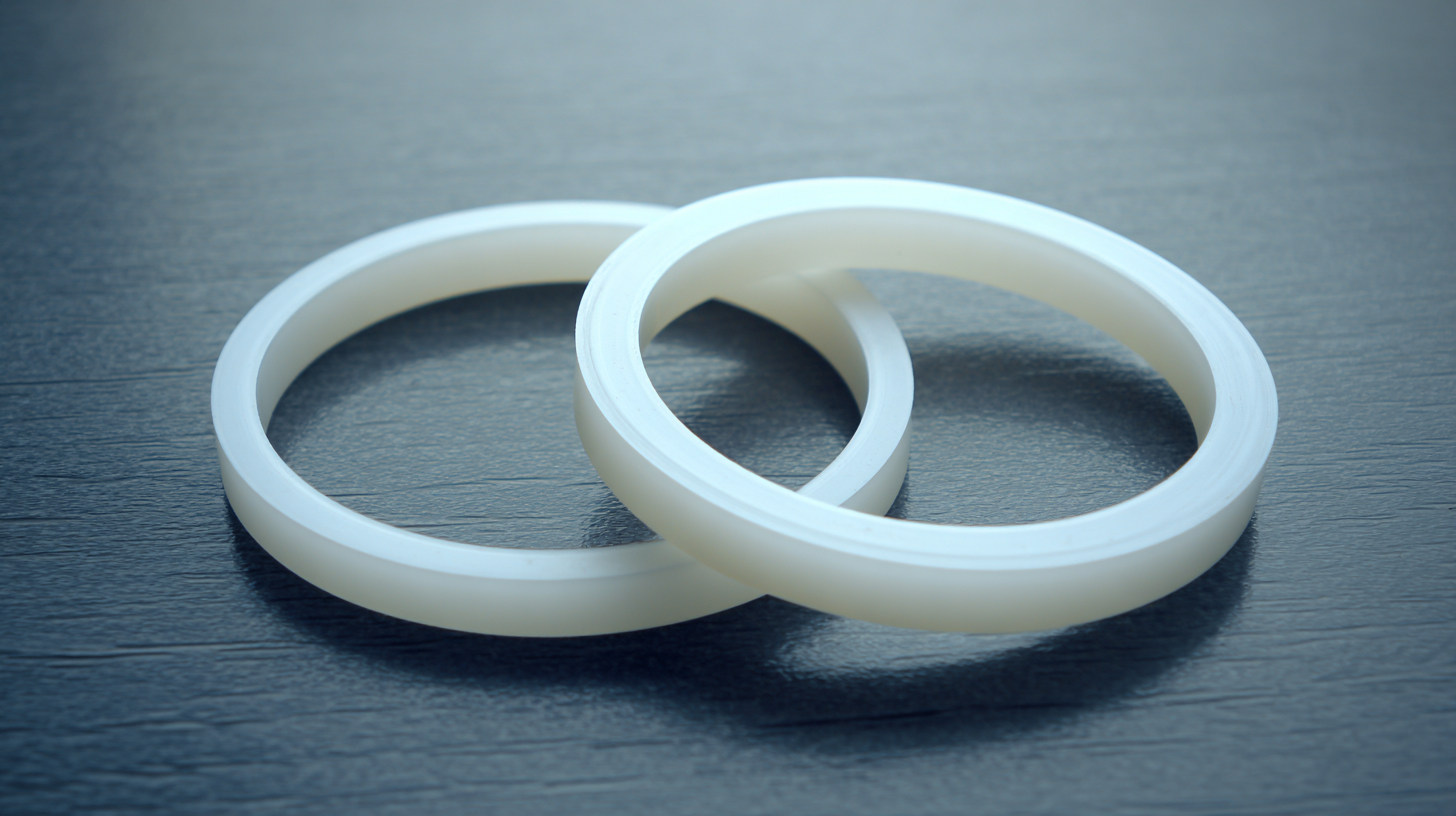

One of the standout features of PTFE gaskets is their low friction coefficient, which reduces wear and tear during operation. This property not only extends the lifespan of the gasket but also contributes to energy efficiency by minimizing leakage and the need for frequent replacements. Additionally, PTFE gaskets are non-stick and can be easily cleaned, making them suitable for sanitary applications in industries such as food processing and pharmaceuticals. The versatility of PTFE sealing gaskets, along with their ability to adapt to varying shapes and sizes, underscores their importance in providing reliable sealing solutions across different sectors.

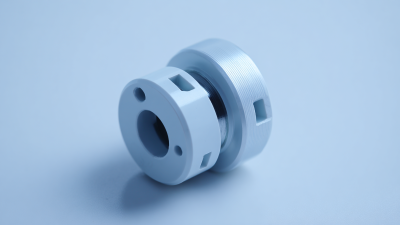

When it comes to selecting the right PTFE sealing gasket for your application, understanding the various types available is crucial. PTFE gaskets are renowned for their chemical resistance and high-temperature stability, making them ideal for numerous industrial settings. In this guide, we'll delve into the most common types of PTFE gaskets: conventional gaskets, envelope gaskets, and expanded PTFE gaskets. Each type has its unique properties tailored to specific needs—conventional gaskets offer robust sealing in static applications, while envelope gaskets provide enhanced sealing capabilities for irregular surfaces. Expanded PTFE gaskets, on the other hand, are ideal for applications requiring flexibility and conformability.

With the industrial gaskets market projected to reach USD 16.84 billion by 2030, businesses are increasingly focusing on leveraging advanced materials that ensure reliability and performance. Innovations in PTFE gasket technology are evolving, catering to specialized applications where conventional materials may fall short. For example, multi-purpose gaskets certified as fire-safe, built to withstand high pressure and temperature, are becoming a standard in critical industries. Such developments are pivotal as they not only enhance operational efficiency but also ensure safety and compliance within various industrial environments.

When selecting a PTFE sealing gasket, several key considerations must guide your decision to ensure optimal performance in your application. First and foremost, it's essential to evaluate the chemical compatibility of PTFE with the substances it will encounter. PTFE is renowned for its resistance to a wide range of chemicals, making it suitable for various industries. However, specific formulations or additives might alter its performance, so confirming compatibility with your operational environment is crucial.

Another vital consideration is the temperature and pressure ratings of the gasket. PTFE gaskets can withstand extreme temperatures and pressures, but it’s necessary to match these ratings with the operating conditions. Operating outside the recommended limits can lead to gasket failure, resulting in leaks and operational downtime. Additionally, the gasket's thickness and design should align with the flange specifications and sealing needs of your equipment. Taking the time to assess these factors will help you select the right PTFE sealing gasket to meet your specific needs, contributing to the reliability and efficiency of your sealing system.

This chart illustrates the key considerations when selecting a PTFE sealing gasket, highlighting the importance level of various factors such as temperature resistance, chemical resistance, pressure resistance, durability, and conformability. Each factor is rated on a scale from 1 to 10 based on its significance in ensuring optimal sealing performance.

When it comes to achieving optimal performance with PTFE gaskets, installation plays a crucial role. Ensuring a clean and smooth surface on both the gasket and the mating surfaces is essential. Cleaning these areas can prevent leaks and prolong the service life of the gasket. Additionally, it’s important to apply the correct torque during installation. Over-tightening can lead to compression deformation, while under-tightening may result in insufficient sealing. Utilizing a calibrated torque wrench can help achieve the right balance.

Moreover, consider the specific application requirements when selecting PTFE gaskets. Factors such as temperature, pressure, and chemical compatibility should guide the choice of gasket thickness and configuration. For instance, certain environments may require gaskets that can endure higher mechanical pressures, while others may benefit from designs that are optimized for thermal expansion. Always refer to manufacturer guidelines to ensure that the selected gasket is suitable for your particular application, thus enhancing performance and ensuring reliability.

| Gasket Type | Temperature Range (°C) | Pressure Rating (Bar) | Chemical Compatibility | Recommended Application |

|---|---|---|---|---|

| Standard PTFE Gasket | -200 to 260 | 20 | Highly resistant to acids and bases | Pipes, valves, and tanks in chemical processing |

| Reinforced PTFE Gasket | -200 to 280 | 50 | Compatible with a wide range of chemicals | High-pressure applications and thermal insulation |

| Expanded PTFE Gasket | -240 to 260 | 10 | Good resistance to aggressive media | Flanges in food and pharmaceutical industries |

| Conductive PTFE Gasket | -200 to 260 | 30 | Electrically conductive substances | Electronics and specialized industrial applications |

When it comes to ensuring the longevity of PTFE sealing solutions, proper maintenance plays a crucial role. One best practice is to regularly inspect the gaskets for signs of wear or damage. This includes checking for any cracks, discoloration, or bulging, which can indicate that the gasket is nearing the end of its lifespan. By identifying these issues early, you can prevent leaks and costly downtime in your operations.

Another important maintenance practice is to keep the sealing surfaces clean and free from debris. Dirt or contaminants can compromise the integrity of the PTFE gasket, leading to leaks or failures. Use non-abrasive cleaning solutions and soft cloths to gently remove any buildup. It’s also advisable to apply the correct lubricant to the sealing surfaces, as specified by the manufacturer, to facilitate smooth operation and reduce friction. By incorporating these maintenance practices, you can significantly extend the life of your PTFE sealing solutions and ensure optimal performance in your applications.