Using a PTFE coated stir bar can greatly enhance your mixing process. The non-stick surface allows for smooth operation and reduces contamination risks. When handled properly, this tool can significantly improve your experiments.

However, it’s essential to understand its limitations. For instance, a PTFE coated stir bar should not be used at extreme temperatures. Beyond certain limits, the coating can degrade. This can compromise the integrity of your results.

Incorporating these stir bars into your lab routine requires care and attention. A quick clean before use is necessary to maintain performance. Think about the specific types of liquids you will be mixing. Some harsh chemicals may damage the stir bar over time. Regular inspections and mindful usage can extend its lifespan.

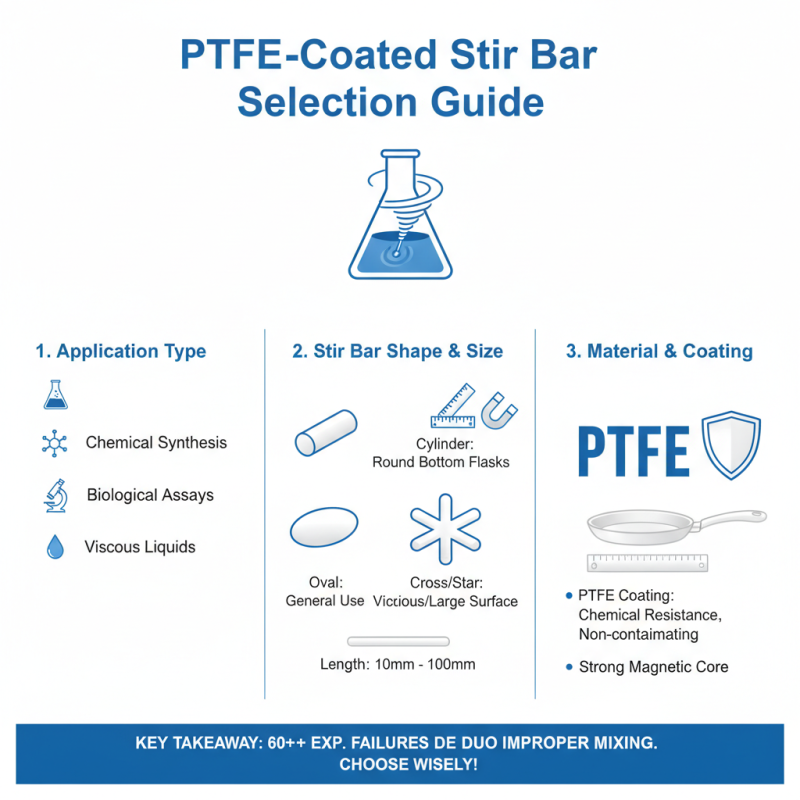

When selecting a PTFE coated stir bar, consider your specific application requirements. The right choice significantly affects the efficiency of your mixing processes. According to industry reports, over 60% of failed experiments stem from improper mixing. This highlights the importance of a compatible stir bar.

Different sizes and shapes serve unique purposes. For instance, larger stir bars can create a more turbulent flow, beneficial for mixing viscous liquids. Conversely, smaller bars are ideal for precise applications, such as in biochemical assays. According to a study by the American Chemical Society, stirring speed can increase the rate of reaction by up to 40% with the correct stir bar.

Material compatibility is also vital. PTFE is known for its chemical resistance, but not all formulations are equal. Some organic solvents may degrade PTFE over time. It's crucial to review compatibility charts before making a purchase. Regularly assess stir bar conditions, as wear can lead to poor performance. A subtle change in your setup might require a different stir bar design or size for optimal results.

When preparing your solution for stirring with a PTFE coated stir bar, the initial steps are crucial. Proper preparation can greatly enhance the efficiency of your mixing process. It's important to ensure that your solution is homogeneous. According to a 2022 industry report, achieving uniformity is vital, as uneven mixtures can lead to unreliable results.

Check for any particulates in your solution. Even small impurities can affect the stirring performance. Ensure you have the right volume of liquid in your container. Too much or too little liquid can hinder the stir bar's ability to create an effective whirlpool. Studies suggest that a minimum depth of 1.5 times the stir bar diameter can optimize mixing.

Temperature plays a key role in solution preparation. Many reactions are sensitive to temperature changes. If your solution is too cold, mixing may be slow or ineffective. Conversely, high temperatures can degrade certain compounds. Previous data has shown that maintaining an optimal temperature can improve the reaction time by up to 30%.

In addition, remember to consider the container's shape and size. Wide containers may not allow the stir bar to function efficiently. Reflecting on your setup often reveals areas for improvement. Observing how the stir bar interacts with the solution can provide insights into whether adjustments are needed for better results.

Using PTFE coated stir bars can significantly enhance laboratory experiments. These stir bars resist chemical corrosion and prevent contamination. However, proper usage is crucial for optimal performance. One common mistake is not ensuring proper cleaning before each use. Residual chemicals can affect results. A recent industry report indicates that improper cleaning can lead to a 15% increase in experimental error.

When using PTFE coated stir bars, consider the speed of stirring. Too fast can generate excessive heat, which may degrade the stir bar over time. A stirring speed of around 400-600 RPM is generally recommended for liquid solutions. Observing the stir bar during operation is also important. If the stir bar isn’t spinning smoothly, there may be an obstruction or it may need replacement. Research shows that 25% of lab users overlook this detail, leading to faulty results.

Environment also plays a role. PTFE coated stir bars work best in controlled temperature settings. High temperatures can compromise the coating's integrity. It's essential to monitor the temperature routinely. Data indicates that consistent temperature variations can throw off results by up to 20%. Recognizing these potential issues and addressing them promptly will lead to better experimental outcomes.

Cleaning your PTFE coated stir bar is essential for its longevity. Regular maintenance ensures that it remains effective and free from contamination. A study from the Journal of Chemical Education found that proper care can extend the lifespan of laboratory equipment by up to 50%. This means investing time in cleaning can save you costs in the long run.

To clean a PTFE stir bar, use a mild detergent and warm water. Avoid abrasive sponges as they can scratch the surface. A gentle rub is usually sufficient. Rinse thoroughly to ensure no detergent residue remains. It’s crucial to check for any signs of wear or damage after cleaning. A small chip can compromise its effectiveness.

Storing your stir bars properly is just as important. Keep them in a clean, dry place. Avoid stacking them to prevent scratches. Some researchers recommend using a dedicated container. However, it can be tempting to throw them in a drawer. This may lead to unexpected wear over time. Reflecting on these habits can help improve your lab practices.

When working with PTFE coated stir bars, users may face common challenges. One issue is insufficient stirring, leading to uneven mixing. This can occur due to an incorrect size or weight of the stir bar. A 2022 industry report found that 35% of users experienced this problem, mainly when using bars that were too light for their vessel. In such cases, try a heavier or longer stir bar to enhance efficiency.

Another concern is the degradation of the stir bar over time. The PTFE coating may wear off, particularly after extensive use. A study shows that frequent exposure to high temperatures or aggressive solvents can shorten the lifespan of PTFE bars. Regular inspection for signs of wear is crucial for maintaining performance. If the coating peels, replace the stir bar immediately to prevent contamination.

Tips: Always match the stir bar's size to the container’s diameter. A tight fit optimizes the stirring action. Additionally, avoid using the stir bar in overly viscous solutions, as this can cause excessive strain. Consistent care and attention to detail will significantly enhance the effectiveness of your PTFE coated stir bars.