In the competitive landscape of global manufacturing, the demand for high-quality components has never been more critical, especially when it comes to crucial products like the PTFE Mixing Plug. As industries worldwide focus on enhancing efficiency and performance, the after-sales support and repair cost strategies for these components are pivotal in ensuring customer satisfaction and loyalty. This blog delves into the innovative approaches that leading manufacturing factories are adopting to improve after-sales services and streamline repair expenses associated with PTFE Mixing Plugs. By examining advancements in technology and best practices in customer engagement, we aim to highlight how these innovations can not only elevate the product's market standing but also reinforce the manufacturers' commitment to excellence in servicing their global clientele.

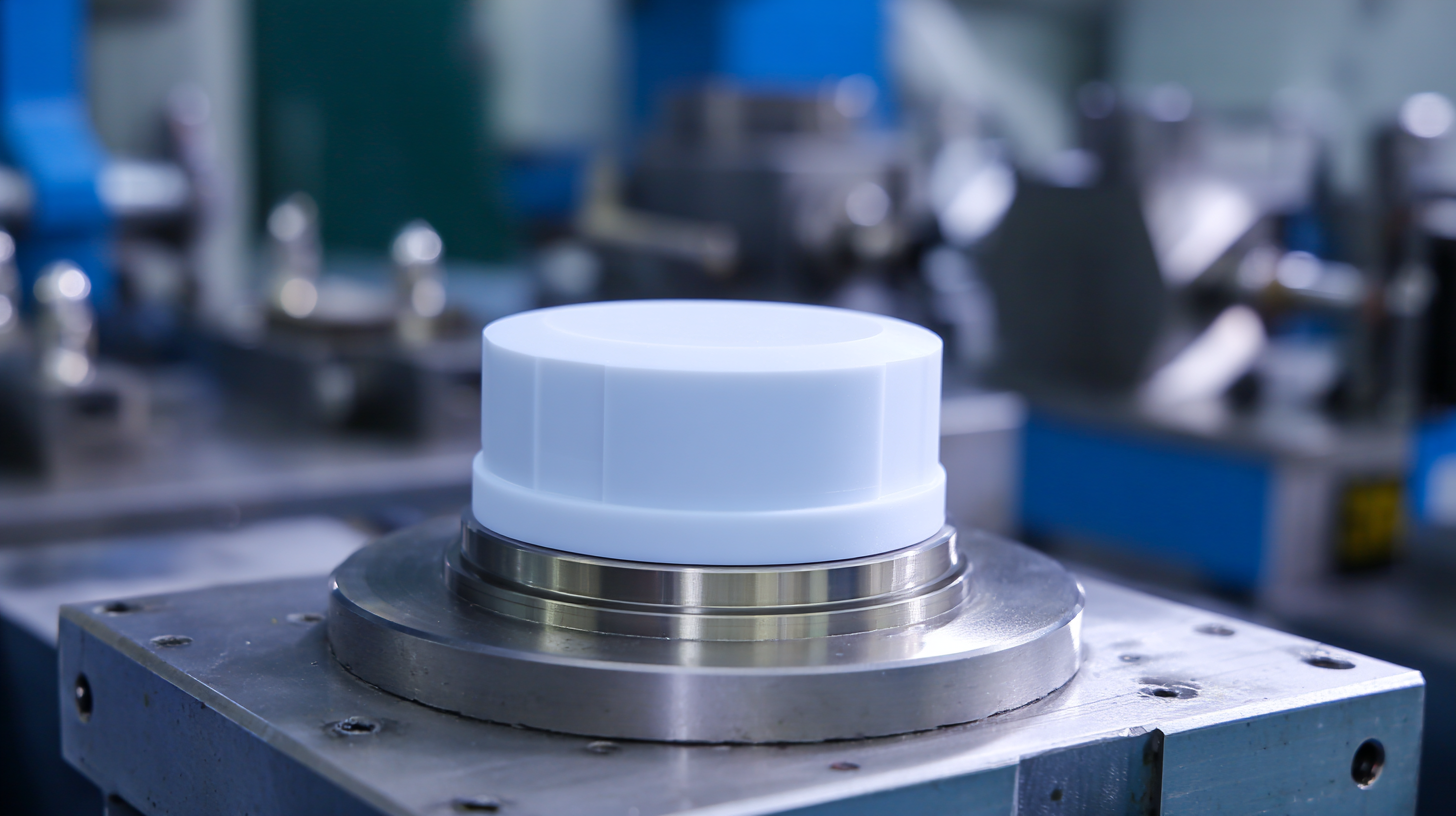

The global manufacturing landscape is witnessing a significant transformation, particularly with the rise of Chinese innovations in the production of PTFE mixing plugs. According to a recent report by Smithers Pira, the advanced materials sector is projected to grow at a compound annual growth rate (CAGR) of 6.2% over the next five years, with PTFE products leading the charge due to their superior chemical resistance and durability. Chinese manufacturers are leveraging cutting-edge technology and efficient production processes, enabling them to lower costs while enhancing product quality. This advantage is reinforcing China's position as a global leader in this niche market.

One key aspect to consider in the evolution of PTFE mixing plugs is the focus on after-sales support and repair cost efficiency. As competition intensifies, manufacturers are adopting comprehensive after-sales strategies that significantly reduce downtime for customers. Implementing robust support systems not only improves customer satisfaction but also contributes to long-term brand loyalty.

**Tip:** For manufacturers seeking to optimize repair cost efficiency, consider investing in digital tracking tools that monitor product performance and predict maintenance needs. Additionally, engaging in feedback loops with customers can provide valuable insights into common issues and enhance product development.

**Tip:** Continuous training for after-sales teams can enhance their proficiency, ensuring they are well-equipped to handle customer queries and repair requirements effectively. This proactive approach can markedly improve operational efficiency and customer trust.

In today's rapidly evolving marketplace, optimizing after-sales support is essential for enhancing customer satisfaction and loyalty. Companies are increasingly recognizing the importance of effective service strategies that not only address customer concerns but also anticipate their needs. By implementing streamlined communication channels and employing data analytics, businesses can gain insights into customer behaviors and preferences, allowing for more personalized and timely support.

Moreover, integrating innovative technologies into after-sales processes can significantly improve service efficiency. Automation and AI tools can assist customer service representatives in managing inquiries seamlessly, reducing response times and increasing overall satisfaction. As organizations adapt to the digital transformation, establishing robust after-sales support frameworks will be pivotal in retaining customers and fostering long-term relationships. By focusing on these strategies, businesses can ensure they remain competitive and responsive to changing customer expectations.

Effective maintenance of PTFE mixing plugs is crucial for minimizing repair costs and enhancing overall efficiency. In industries where these components are integral, leveraging next-generation maintenance strategies can significantly reduce expenses. Recent insights from various sectors indicate that organizations implementing proactive maintenance strategies can lower costs by up to 30% by preventing issues before they escalate. This is particularly relevant given the insights from the life sciences sector, where optimized facility management strategies have proven beneficial in improving reliability and cutting capital expenses.

**Tips for Minimizing PTFE Plug Maintenance Costs:**

1. **Implement Predictive Maintenance:** Utilize IoT sensors to gather real-time data on the condition of PTFE plugs. Predictive maintenance not only helps in anticipating failures but also reduces downtime, leading to long-term cost savings.

2. **Adopt Total Cost of Ownership (TCO) Approach:** Consider the comprehensive costs associated with PTFE plugs, including installation, maintenance, and eventual replacement. By analyzing these factors, organizations can identify opportunities to optimize spending and enhance sustainability.

3. **Regular Training and Skill Development:** Investing in the training of maintenance personnel ensures they are equipped with the latest best practices. A well-informed team can handle repairs efficiently, thus reducing both direct and indirect repair costs.

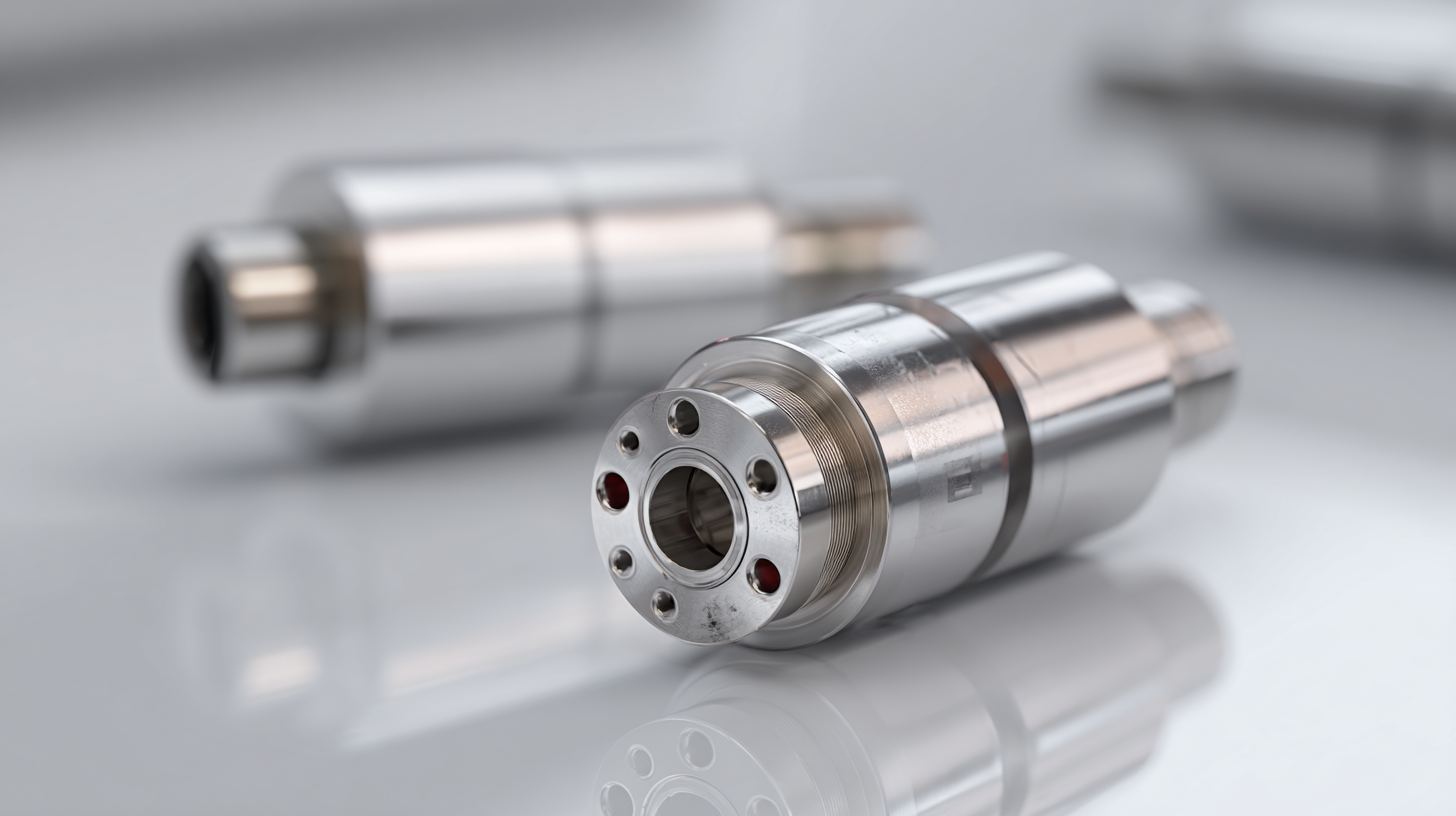

The future of PTFE mixing plug technology is set to be shaped significantly by advancements in various digital and manufacturing technologies. According to a recent report by MarketsandMarkets, the global market for advanced polymers, including PTFE, is expected to reach $30.9 billion by 2026, growing at a CAGR of 6.5%. This growth highlights the increasing demand for high-performance materials that offer superior chemical resistance and thermal stability. Companies are now exploring smart manufacturing processes, leveraging IoT devices and AI-driven analytics, to enhance the efficiency of production and improve product quality.

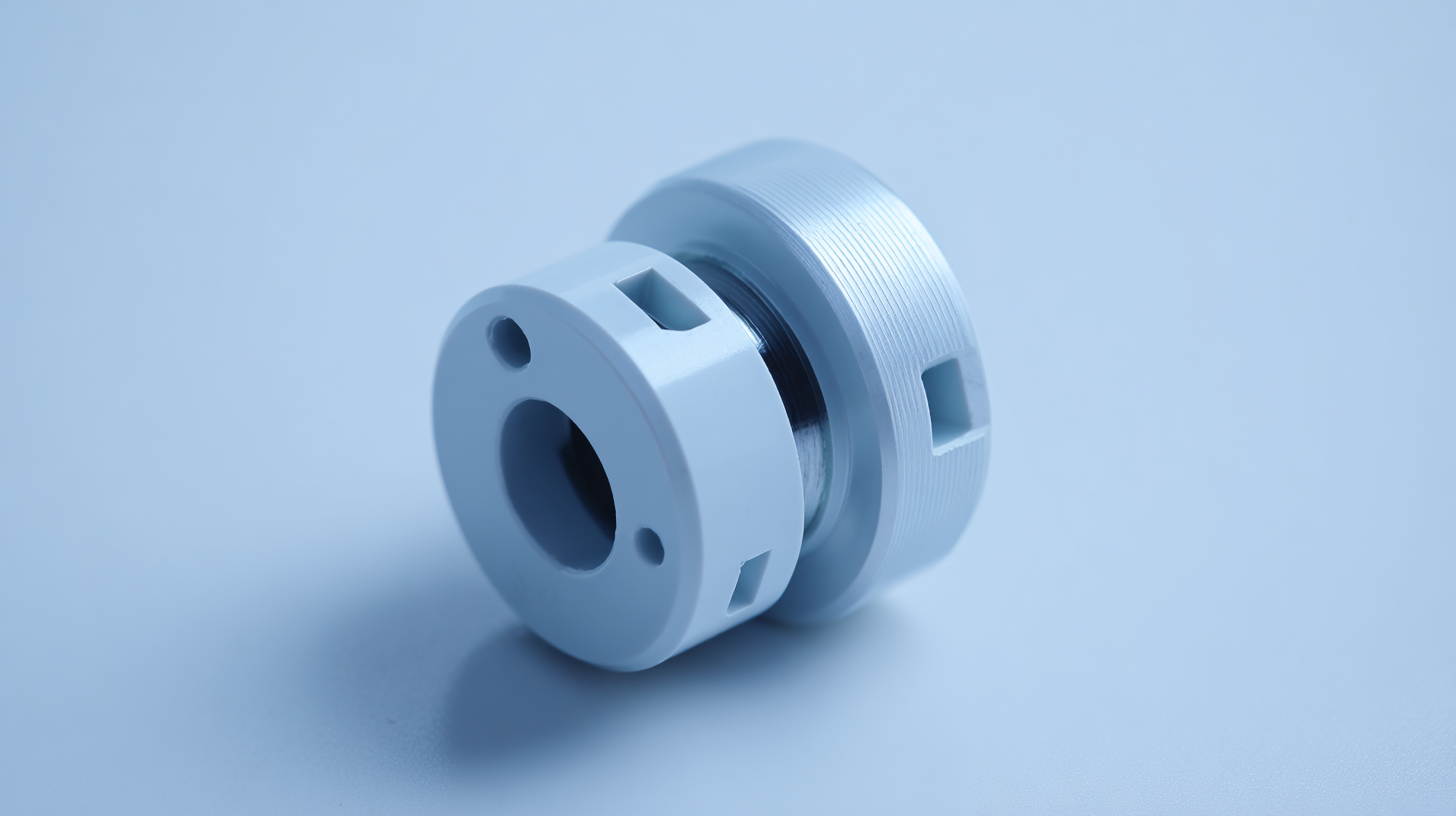

Additionally, emerging technologies such as 3D printing are poised to revolutionize the way PTFE mixing plugs are designed and manufactured. A study from Wohlers Associates estimates that the 3D printing industry is projected to exceed $35 billion by 2024. This capability allows for more complex geometries and customized solutions, reducing lead times and production costs. By embracing these innovations, manufacturers can not only streamline operations but also provide tailor-made products that meet specific customer needs, thereby enhancing after-sales support and ensuring cost efficiency in repairs and replacements.

In today's highly competitive marketplace, understanding global trends and adapting to customer needs are crucial for PTFE product development. By studying successful strategies from various international markets, businesses can uncover innovative approaches that drive efficiency and enhance product quality. For instance, integrating advanced technology in manufacturing processes can significantly reduce defects and improve the overall performance of PTFE mixing plugs, leading to increased customer satisfaction and loyalty.

Moreover, lessons learned from global competitors can help inform after-sales support strategies. Companies that invest in robust support systems not only improve customer experiences but also gather valuable feedback that can inform future innovations. Emphasizing transparency regarding repair costs and operational efficiency in after-sales can set a brand apart in a crowded field. This competitive edge can ultimately translate into sustained growth and a more resilient business model, as stakeholders become more confident in the reliability and durability of PTFE products.

| Aspect | Value | Comments |

|---|---|---|

| After Sales Support Rating | 85% | High customer satisfaction |

| Average Repair Cost | $150 | Cost-effective solutions implemented |

| Innovation Investment | $500,000 | Focus on new material advancements |

| Customer Feedback Frequency | Monthly | Regularly collected for improvements |

| Market Growth Rate | 10% per year | Positive trend in PTFE product demand |