In today's fast-paced laboratory environments, efficiency is paramount to successful outcomes and resource optimization. Recent industry reports indicate that laboratories that implement advanced mixing technologies can increase productivity by up to 30%, leading to significant cost savings and improved workflow. One essential tool contributing to this enhancement is the Lab PTFE Magnetic Stirrer Bar. These stirrer bars, known for their durability and chemical resistance, allow for precise and uniform mixing of solutions, which is crucial in various applications from pharmaceuticals to academic research.

By reducing mixing times and ensuring consistent results, Lab PTFE Magnetic Stirrer Bars play a vital role in streamlining laboratory processes and improving overall lab efficiency.

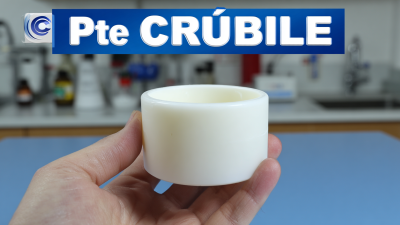

PTFE magnetic stirrer bars have become essential tools in modern laboratory settings, primarily due to their unique properties and benefits. One of the key advantages of PTFE, or polytetrafluoroethylene, is its excellent chemical resistance, making it ideal for use in experiments involving harsh solvents and aggressive reagents. According to a report from the American Chemical Society, utilizing PTFE magnetic stirrer bars can significantly reduce contamination risk, resulting in more accurate and reproducible results. This is crucial in sensitive environments where even minimal impurities can alter experimental outcomes.

Moreover, PTFE magnetic stirrer bars contribute to enhanced lab efficiency by facilitating efficient mixing without the risk of sticking or jamming. Their smooth surface significantly minimizes the wear and tear compared to traditional stirring devices, leading to longer service life and reduced maintenance costs. The Laboratory Equipment Manufacturers Association has noted that the adoption of high-quality stirring tools, including PTFE stirrer bars, can improve workflow efficiency by up to 25%. This increase in productivity allows researchers to allocate more time and resources to critical experiments rather than equipment issues, ultimately accelerating the pace of scientific discovery.

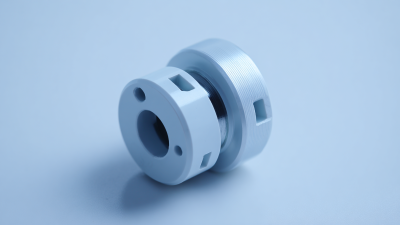

When it comes to enhancing lab efficiency, selecting the right type of PTFE magnetic stirrer bars can make a significant difference. There are various styles and sizes available, each designed for specific applications and substances. Generally, PTFE stirrer bars are known for their chemical resistance and durability, but focusing on their shapes can also optimize their performance. For example, cylindrical stirrer bars provide even mixing in viscous liquids, while star-shaped bars can create stronger turbulence in more fluid solutions.

**Tip:** When choosing a stirrer bar, consider not only the material but also the geometry. The right shape will cater to the viscosity and the mixing requirements of your specific application. If you need to mix larger volumes, opting for longer stirrer bars can yield better results in terms of efficiency and homogeneity.

Additionally, the strength of the magnetic field produced by your stirrer is crucial. A stronger magnet will keep the stirrer bar spinning consistently, ensuring effective mixing. Therefore, always verify that your stirrer is compatible with the bar type you select. This compatibility will help eliminate issues like slippage, which can hamper your lab's productivity.

**Tip:** Regularly inspect your stirrer bars for wear and tear. A damaged stirrer can disrupt your experiments and lead to inaccurate results, so investing in high-quality PTFE bars and replacing them as needed will help maintain optimal laboratory performance.

| Type of PTFE Stirrer Bar | Length (cm) | Magnet Strength (N) | Stirring Speed (RPM) | Application Suitability |

|---|---|---|---|---|

| Standard PTFE Stirrer Bar | 5 | 2.5 | 200-800 | General Mixing |

| Twist-Style PTFE Stirrer Bar | 7 | 3.0 | 300-1000 | High Viscosity Liquids |

| Coated PTFE Stirrer Bar | 10 | 3.5 | 200-900 | Corrosive Samples |

| Oval PTFE Stirrer Bar | 5 | 2.0 | 150-750 | Low Volume Solutions |

| Rectangular PTFE Stirrer Bar | 8 | 4.0 | 250-850 | Suspended Solids |

In modern laboratories, efficiency and cost-effectiveness are essential for optimal performance.

PTFE (Polytetrafluoroethylene) magnetic stirrer bars have emerged as a favored tool among researchers seeking both accuracy and durability in their experiments. Evaluating the cost-effectiveness of these stirrer bars reveals numerous benefits that can significantly enhance lab processes.

PTFE (Polytetrafluoroethylene) magnetic stirrer bars have emerged as a favored tool among researchers seeking both accuracy and durability in their experiments. Evaluating the cost-effectiveness of these stirrer bars reveals numerous benefits that can significantly enhance lab processes.

By utilizing PTFE magnetic stirrer bars, labs can achieve superior chemical resistance and reduced contamination risks. Unlike traditional materials, PTFE is non-reactive and can withstand a broader range of temperatures and pH levels. This reliability not only saves time during experiments by reducing the need for frequent replacements but also minimizes potential downtime associated with equipment failures. Investing in high-quality PTFE magnetic stirrer bars may initially seem costlier, but the long-term savings from fewer replacements and increased efficiency justify the expense.

Furthermore, the streamlined operation of PTFE magnetic stirrer bars directly correlates with improved workflows. These stirrer bars are designed for optimal magnetic coupling, offering superior stirring performance without the risk of jamming or damage. This enhances lab productivity, allowing researchers to focus on critical tasks while ensuring consistent and even distribution of chemicals. Overall, the adoption of PTFE magnetic stirrer bars demonstrates a smart investment in both enhanced lab efficiency and cost-effectiveness.

The efficiency of stirring in a laboratory setting can significantly impact the outcomes of experiments. A comparative analysis reveals that using high-quality PTFE magnetic stirrer bars can elevate the consistency and quality of experimental results. PTFE, known for its excellent chemical resistance and low friction properties, allows for smoother interactions between stirrer bars and samples, minimizing contamination and ensuring a more homogenous mixture. This homogeneity is critical, especially in reactions where precise concentrations of reagents are required.

Moreover, the effectiveness of stirring is not only about speed but also about the design of the stirrer bars themselves. The shape and size of the PTFE stirrer bars contribute to how well they create vortexes, thus enhancing the mixing of solutions. Experiments that involve heat transfer, reactions with gases, or the dissolution of solids often yield more accurate results with optimized stirring techniques. By investing in appropriate stirrer bars and understanding their impact on experimental parameters, researchers can ensure that their findings are both reliable and reproducible.

When selecting PTFE magnetic stirrer bars, adhering to industry standards and best practices is crucial for maximizing lab efficiency. According to a report by the American Chemical Society, the improper selection of stirring equipment can lead to inefficiencies that increase operational costs by up to 30%. To mitigate this, labs should consider the size and shape of the stirrer bar in alignment with the volume of the liquid being stirred. For example, longer bars provide a better magnetic field interaction, while wider bars can prevent the formation of dead zones.

Tip: Always choose stirrer bars that match the viscosity of your liquids. High-viscosity samples often require specialized stirrer designs to ensure effective mixing. Additionally, select PTFE-coated bars as they offer chemical resistance, eliminating the risk of contamination during experiments.

It's also vital to consider the power of the magnetic stirrer itself. A stirrer with insufficient magnetic power may not effectively engage larger or heavier stirrer bars. An optimal stirrer should generate a magnetic field capable of handling a range of stirrer bar sizes, ideally supported by performance data from the manufacturer.

Tip: Regularly check and maintain your equipment to ensure optimal performance. Small adjustments in stirrer settings can significantly enhance mixing efficiency and improve overall laboratory productivity.