In the world of laboratory procedures, precision and efficiency are paramount, especially when it comes to mixing and stirring solutions. One tool that has revolutionized the way experiments are conducted is the PTFE stir bars retriever. This simple yet effective device allows researchers to easily retrieve magnetic stir bars from various types of containers, minimizing the risk of contamination and ensuring that samples are handled safely. However, to make the most out of this innovative tool, certain best practices should be followed.

Understanding how to use the PTFE stir bars retriever efficiently can enhance lab workflows and save valuable time. From selecting the right size retriever to mastering the technique of extraction, there are several key tips that can significantly improve your laboratory experience. Whether you are an experienced scientist or a newcomer to the lab environment, these essential strategies will help you harness the full potential of the PTFE stir bars retriever, ensuring optimal performance and reliable results in your experimental endeavors.

PTFE stir bars, commonly used in laboratory settings, offer several advantages over traditional glass or metal stirrers. Made from polytetrafluoroethylene, PTFE is a non-reactive, chemically resistant material that is ideal for mixing a wide range of substances without contamination. According to the latest market reports, the demand for PTFE products in the laboratory equipment sector has increased by approximately 15% in the past five years, attributed to their versatility and enhanced performance in challenging environments.

When using PTFE stir bars, it is essential to understand their specific properties to utilize them effectively. They have a low coefficient of friction, which allows them to stir more smoothly and efficiently. Laboratory studies indicate that mixing efficiency can improve by up to 20% when PTFE stir bars are utilized properly, particularly in viscous solutions. Additionally, their inert nature ensures that they do not interact with the chemicals being mixed, making them a favorite for reactions that require precise control over conditions.

Moreover, proper handling and maintenance of PTFE stir bars can prolong their lifespan and ensure consistent performance. Avoiding exposure to extreme temperatures or harsh mechanical stress can prevent damage and wear. An estimated 30% of stir bar failures can be traced back to improper usage, highlighting the importance of adherence to recommended practices. Understanding these critical aspects helps researchers maintain the integrity of their experiments while achieving optimal mixing results.

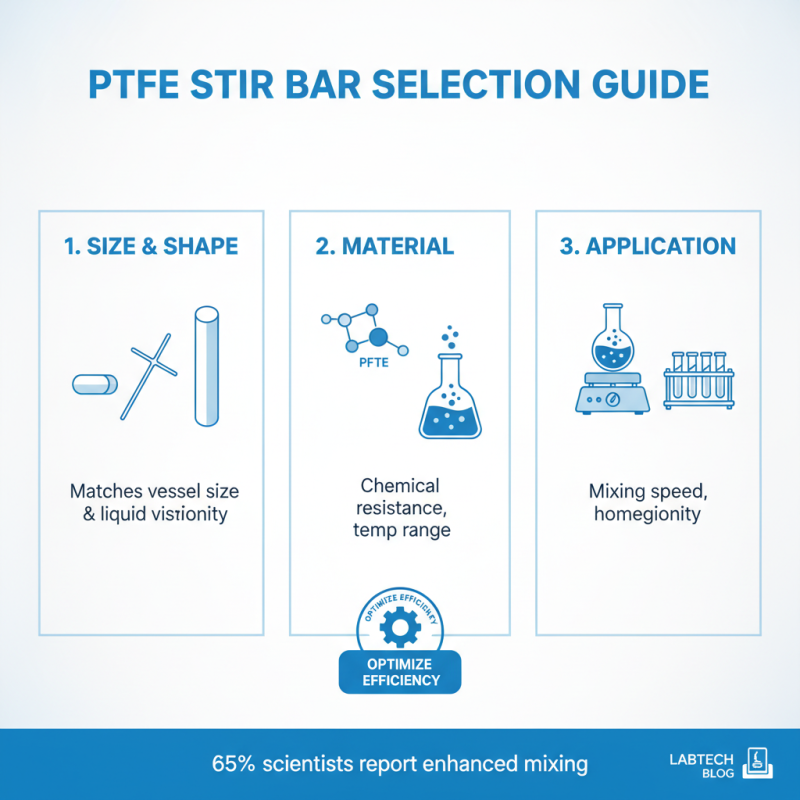

When selecting the right PTFE stir bar for your application, it's crucial to consider several key factors that can significantly affect your process efficiency and results. PTFE, known for its excellent chemical resistance and low friction properties, is favored in a variety of laboratory applications. According to a report by the Journal of Laboratory Technology, more than 65% of scientists indicate that the choice of stir bar directly enhances their mixing effectiveness.

One essential tip is to match the stir bar size with the volume of the liquid being mixed. Using a stir bar that is too small can lead to ineffective mixing, while a size that's too large may create unnecessary friction, resulting in wear and tear on equipment. Additionally, selecting a stir bar with the right shape is vital. For viscous liquids, a larger, more robust stir bar shape can significantly improve rotational movement and achieve a homogeneous mixture faster.

Another aspect to consider is the temperature stability of the PTFE stir bars. Data from a recent industry survey highlights that around 40% of laboratory errors stem from improper temperature management. Ensuring the chosen stir bar can withstand the required temperature range is critical for maintaining consistency in your experiments. Additionally, always ensure the stir bar is compatible with the solvents and chemicals being used, as this can prevent contamination and ensure accurate results in sensitive applications.

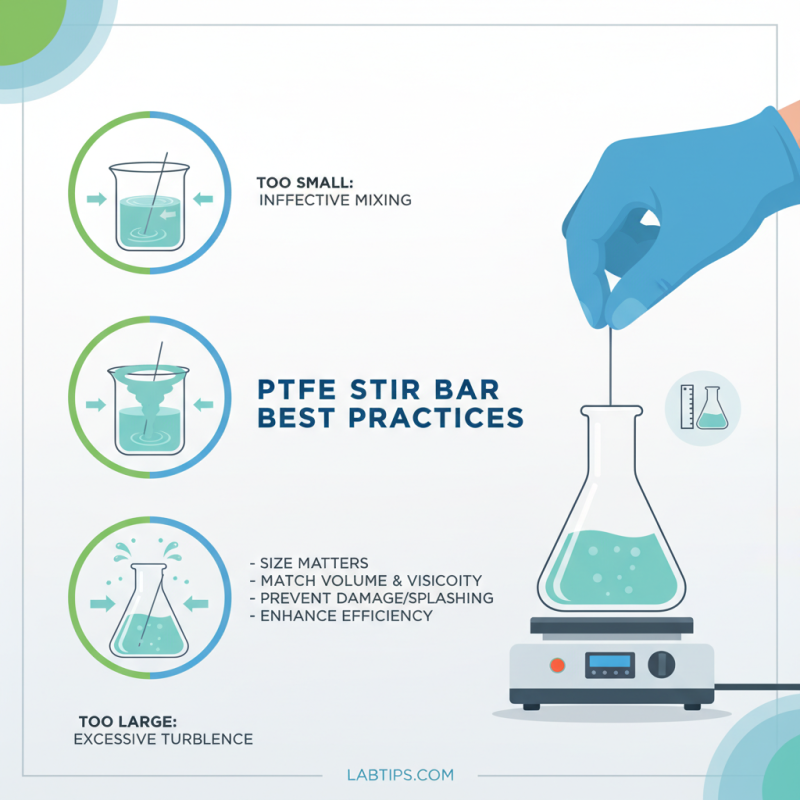

When working with PTFE stir bars in the laboratory, effective usage is paramount for achieving optimal results in stirring and mixing reactions. One best practice is to ensure that the stir bar is appropriately sized for the volume and type of solution being mixed. Using a stir bar that is too small can lead to ineffective mixing, while an oversized bar may cause excessive turbulence, potentially damaging sensitive samples. It’s essential to select a stir bar that can comfortably fit within the vessel while also allowing for adequate movement to enhance stirring efficiency.

Another important consideration is the proper placement of the stir bar within the container. To prevent the stir bar from sticking to the bottom or sides of the vessel, ensure that it starts in a central position. This will facilitate smoother rotation and allow for even mixing across the entire volume of the solution. Additionally, maintaining the correct speed of rotation is crucial; setting the stirring speed too high can cause splashing, whereas too low a speed will result in incomplete mixing. Monitoring the viscosity of the solution and adjusting the stirring speed accordingly can significantly improve performance and outcomes in various laboratory applications.

When it comes to cleaning and maintaining PTFE stir bars, ensuring their longevity is essential for optimal performance in any laboratory setting. One of the first steps in proper maintenance is to avoid exposing the stir bars to harsh chemicals. Instead, use mild detergents and warm water to clean them after each use. This not only protects the integrity of the PTFE coating but also prevents cross-contamination in future experiments.

Another important tip is to regularly inspect your stir bars for signs of wear and tear. If you notice any scratches or damage, it may be time to replace the stir bar to maintain the quality of your results. Additionally, storing the stir bars in a dedicated, cushioned container can prevent accidental damage and keep them clean. By taking these simple precautions, you can ensure that your PTFE stir bars remain in excellent condition and serve you well over time.

Lastly, always allow your stir bars to air dry completely before storing them. Moisture can lead to mold growth or other contaminants that may impact your work. By following these cleaning and maintenance practices, you can extend the lifespan of your PTFE stir bars and enhance your laboratory efficiency.

When working with PTFE stir bars, troubleshooting common issues can significantly enhance your experience and efficiency in the lab. One frequent problem encountered is the stir bar being stuck to the bottom of the vessel. This can occur due to insufficient lubrication or inadequate stirring speeds. According to a recent industry report, optimal stir speeds generally range from 300 to 800 RPM, depending on the viscosity of the solution. Ensuring that you adjust your stirrer to the correct speed can help prevent the stir bar from adhering too strongly to the vessel's surface.

Another issue often faced is the deterioration of the stir bar due to chemical exposure. PTFE is renowned for its chemical resistance, but not all conditions are suitable. Regular inspections are crucial; if you notice significant wear or deformation, it may be time to replace the stir bar. A tip to prolong the life of your stir bars is to always use them within the recommended temperature range indicated by the manufacturer, as extreme temperatures can compromise the integrity of the material.

To enhance the efficiency of your stirring process, consider using a guide to quickly match PTFE stir bar sizes with your flask or vessel. The most effective stir bars usually have a length that is about one-third the diameter of the flask. This relationship allows for optimal movement and fluid dynamics, reducing the chances of clumping and ensuring thorough mixing in various solutions. By keeping these troubleshooting tips and best practices in mind, you can effectively use PTFE stir bars and ensure smooth operation in your experimental setups.