In the rapidly evolving landscape of advanced manufacturing, the role of materials like PTFE (polytetrafluoroethylene) is becoming increasingly pivotal. With the global PTFE market expected to reach $3.5 billion by 2028, driven by its superior chemical resistance and low friction properties, industries are beginning to recognize the advantages of incorporating PTFE stir rods into their production processes. These innovative tools are not only essential for ensuring consistent and efficient mixing in various applications but also significantly enhance the durability and reliability of manufacturing operations. As companies strive for higher efficiency and better product quality, the demand for PTFE stir rods, which offer a unique combination of thermal stability and non-reactivity, is set to surge. This guide will explore the future potential and applications of PTFE stir rods in advanced manufacturing solutions, highlighting their significance in shaping the industry's advancements.

In advanced manufacturing solutions, the functionality of PTFE stir rods extends far beyond their basic mixing capabilities. These rods play a pivotal role in enhancing material processing efficiency, especially in environments that require precision and high-temperature resistance. Their chemical inertness and low surface energy make PTFE stir rods ideal for blending materials without contamination, ensuring that the final products maintain their desired properties.

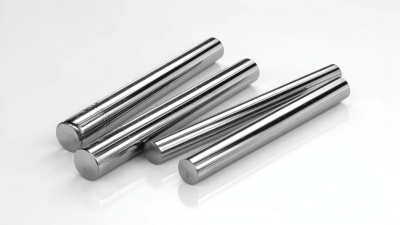

Tips: When using PTFE stir rods, it's essential to choose the right diameter and length to suit your specific mixing requirements. A longer rod can be advantageous for deep containers, while a wider diameter can improve the flow of viscous materials.

Additionally, employing PTFE stir rods can significantly reduce wear and tear on mixing equipment. Their durability means less downtime for maintenance, ultimately leading to a more streamlined manufacturing process. When implementing these rods, consider optimizing your mixing speeds for different materials to further enhance processing efficiency.

Tips: Always monitor the temperature and viscosity of the materials being mixed, as these factors can influence the effectiveness of your PTFE stir rods. Adjusting your technique based on these variables will help maximize your outcomes in material processing.

In the realm of advanced manufacturing, PTFE stir rods have emerged as a pivotal component, driving innovation across various high-tech applications. Their exceptional chemical resistance and low friction properties make them ideal for use in environments where traditional materials might falter. Industries ranging from pharmaceuticals to electronics are increasingly adopting PTFE stir rods, leveraging their durability to enhance production efficiency and product quality. These rods are not just tools; they represent a shift towards more sustainable manufacturing practices, allowing for cleaner processes that minimize contamination risks.

Moreover, the versatility of PTFE stir rods fosters innovative application development. Engineers and manufacturers are exploring their use in automated systems and robotics, where precision and reliability are paramount. In battery manufacturing, for instance, the ability to handle highly reactive materials without degradation is critical. As technology evolves, so too does the potential for these rods to enhance performance in advanced manufacturing, pushing the boundaries of what is possible and enabling breakthroughs in product development. With the continued rise of smart manufacturing solutions, PTFE stir rods are poised to play an even larger role in shaping the future of industry.

In the realm of advanced manufacturing, the choice of mixing solutions significantly impacts productivity and product quality. PTFE stir rods stand out for their chemical resistance and low friction properties, making them ideal for mixing aggressive substances. According to a report by MarketsandMarkets, the global demand for PTFE products is projected to grow at a CAGR of 6.1% from 2022 to 2027, indicating a robust shift towards materials that enhance efficiency in manufacturing processes.

Comparatively, alternative mixing solutions, such as stainless steel stir rods or glass stirrers, offer their own advantages, yet they fall short in specific applications. Stainless steel rods, while durable, can react with certain chemicals, potentially contaminating the mixture. Glass stirrers, while chemically inert, are prone to breakage, leading to operational downtime. A study published in the Journal of Materials Science has reported that the lifespan of PTFE stir rods can exceed five years under consistent use, whereas alternatives may require more frequent replacements. This longevity not only reduces operational costs but also ensures continuous production, making PTFE stir rods a more sustainable option in advanced manufacturing solutions.

The demand for PTFE stir rods in advanced manufacturing solutions is on the rise, driven by several market trends that reflect a broader shift in industrial practices. As industries increasingly prioritize efficiency and sustainability, PTFE’s unique properties—such as its chemical resistance, low friction, and high thermal stability—make it an ideal choice for various applications. These characteristics not only facilitate smoother operations but also extend the lifespan of equipment, ultimately leading to lower maintenance costs.

Additionally, the strengthening push towards automation and enhanced production processes across numerous sectors further amplifies the need for high-performance materials like PTFE. The increasing adoption of innovative manufacturing techniques, alongside the growth of industries such as pharmaceuticals and food processing, contributes to the growing market for PTFE stir rods. As companies strive to meet higher standards and improve product quality, the focus on reliable and durable materials is set to reshape the future landscape of manufacturing, ensuring that PTFE remains at the forefront of these advancements.

In recent years, PTFE (Polytetrafluoroethylene) technology has emerged as a game-changer in advanced manufacturing practices. According to a recent market report by Grand View Research, the global PTFE market is expected to reach USD 4.21 billion by 2025, growing at a CAGR of 5.5%. This significant growth underscores the increasing demand for PTFE stir rods, which are critical in various manufacturing processes due to their chemical resistance and non-stick properties. Industries ranging from pharmaceuticals to aerospace benefit from these attributes, enabling more efficient production cycles and enhanced product quality.

The incorporation of PTFE stir rods in manufacturing not only improves process efficiency but also minimizes the risk of contamination, a critical factor in sectors like food and healthcare. For example, a study by ResearchAndMarkets indicates that nearly 30% of businesses in the chemical sector have reported enhanced compliance with safety regulations by utilizing PTFE materials. As manufacturers continue to prioritize sustainability and efficiency, the adoption of innovative materials such as PTFE will play a vital role in shaping the future landscape of advanced manufacturing solutions.