In modern laboratory settings, the selection of appropriate tools and materials is paramount to ensuring experimental accuracy and safety. One such critical component is the PTFE centrifuge tube, renowned for its chemical resistance and stability. According to a recent report by ResearchAndMarkets, the demand for advanced laboratory equipment, including high-performance centrifuge tubes, is projected to grow significantly, with the global laboratory plastic consumables market reaching approximately $3.5 billion by 2026. This trend underscores the importance of choosing the right PTFE centrifuge tube, as it directly impacts the reliability of test results and the longevity of laboratory processes. As laboratories are constantly evolving in their needs—from biomedical research to materials science—this ultimate guide will equip you with the essential knowledge to select the perfect PTFE centrifuge tube tailored to your specific laboratory requirements.

Polytetrafluoroethylene (PTFE) is a high-performance polymer that is widely used in laboratory settings due to its unique properties, including chemical resistance, non-stick nature, and thermal stability. According to a recent report by the MarketsandMarkets research group, the global demand for PTFE in laboratory applications is expected to grow at a CAGR of 5.2% from 2021 to 2026, highlighting the increasing reliance on this versatile material in various scientific fields. Its exceptional resistance to corrosive chemicals makes PTFE centrifuge tubes ideal for applications involving aggressive solvents and acids, commonly found in organic chemistry, biochemistry, and environmental research.

In addition to chemical inertness, PTFE also boasts a high-temperature tolerance that extends its usability in diverse laboratory environments. A study published in the Journal of Applied Polymer Science noted that PTFE maintains its mechanical integrity up to temperatures of around 260°C, thus enabling researchers to perform high-temperature centrifugation without risk of tube degradation. This feature is particularly beneficial when isolating sensitive compounds or conducting reactions that require elevated temperatures. As laboratories continuously seek materials that can withstand harsh conditions while ensuring accurate and reliable results, the role of PTFE continues to solidify in the realm of analytical and preparative techniques.

When selecting PTFE centrifuge tubes for laboratory applications, several key factors must be prioritized to ensure optimal results. Firstly, it's essential to consider the chemical compatibility of the PTFE material with the samples being processed. According to a report by the American Chemical Society, PTFE exhibits exceptional resistance to a wide range of acids and bases, making it suitable for applications involving corrosive substances. Choosing tubes that can withstand these environmental conditions prevents contamination and ensures the integrity of your research.

Another crucial aspect is the temperature tolerance of the centrifuge tubes. Data from the International Journal of Engineering and Technology indicates that high-quality PTFE tubes can typically endure temperatures ranging from -200°C to 260°C. This wide temperature range allows for diverse applications, from cryogenic processes to high-temperature experiments, significantly increasing the versatility of your laboratory equipment. Lastly, consider the specific volume and dimensions required for your experiments, as PTFE centrifuge tubes come in various sizes to cater to different sample volumes, enhancing efficiency and precision in laboratory workflows.

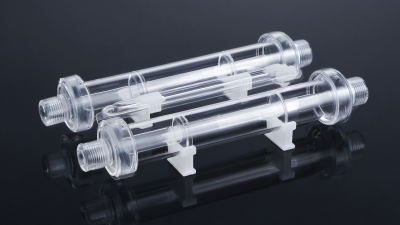

When selecting the right PTFE centrifuge tube for your laboratory, size, shape, and volume options are critical factors that can significantly impact your experiments' efficacy and accuracy. PTFE centrifuge tubes come in various sizes, typically ranging from small 1.5 mL volumes to larger 50 mL formats. Small tubes are excellent for isolating DNA, RNA, and proteins, while larger volumes are ideal for high-throughput applications, where multiple samples are processed simultaneously.

In addition to size, the shape of the tubes plays a vital role in their compatibility with different centrifuge models. Some tubes are designed with conical bottoms to optimize sedimentation and facilitate easier sample retrieval. Additionally, the volume options can affect the concentration and handling of samples, so researchers must consider the specific requirements of their assays. Choosing the appropriate PTFE centrifuge tube ensures better sample integrity and enhances the reproducibility of experimental outcomes, making it a fundamental step in laboratory preparation.

When utilizing PTFE centrifuge tubes in laboratory settings, proper maintenance is crucial to ensure longevity and optimal performance. According to a 2022 industry report from the American Laboratory Association, regular cleaning and inspection of PTFE tubes can extend their life by up to 30%. It is recommended to rinse these tubes with a compatible solvent immediately after use to prevent residue build-up. Gentle scrubbing with a soft brush can help remove stubborn debris while preserving the integrity of the PTFE material.

Best practices also include proper storage conditions to avoid any degradation. The same report emphasizes that PTFE is resistant to a wide range of chemicals but should be stored away from extreme temperatures and direct sunlight. Maintaining a stable environment not only conserves the physical properties of the tubes but also ensures consistent results in experiments. Implementing these maintenance strategies will significantly reduce the risk of sample contamination and equipment failure, thus enhancing laboratory efficiency and reliability.

When selecting PTFE centrifuge tubes for your laboratory, it's crucial to avoid common pitfalls that could compromise your experiments. One common mistake is overlooking the specifications of the tube. Different experiments may require varying tube thicknesses or dimensions, and using the wrong size can lead to sedimentation issues or inefficient centrifugation. Always ensure that the tubes are compatible with your centrifuge model and capable of withstanding the required rotational speeds.

Another frequent error is neglecting to consider the chemical compatibility of the tubes. PTFE is known for its excellent resistance to chemicals, but not all PTFE tubes are created equal. Some may have specific limitations against certain solvents or compounds. Failing to account for this can result in tube degradation and contamination of your samples. Therefore, it's essential to verify that the selected PTFE tubes meet the chemical requirements of your intended applications, ensuring reliable and accurate results every time.

| Feature | Importance | Common Mistakes |

|---|---|---|

| Size and Capacity | Ensures proper fit for samples | Choosing a size too large or too small |

| Material Quality | Resistant to chemicals and temperature | Overlooking material specifications |

| Sterility | Reduces contamination risk | Not considering sterility requirements |

| Closure Type | Provides secure sealing | Ignoring the sealing mechanism |

| Temperature Resistance | Critical for heat-sensitive samples | Selecting tubes with inadequate temperature ratings |

| Volume Graduation | Allows accurate measurements | Neglecting the graduated markings |

| Compatibility with Centrifuge | Prevent equipment damage | Using tubes not rated for specific models |