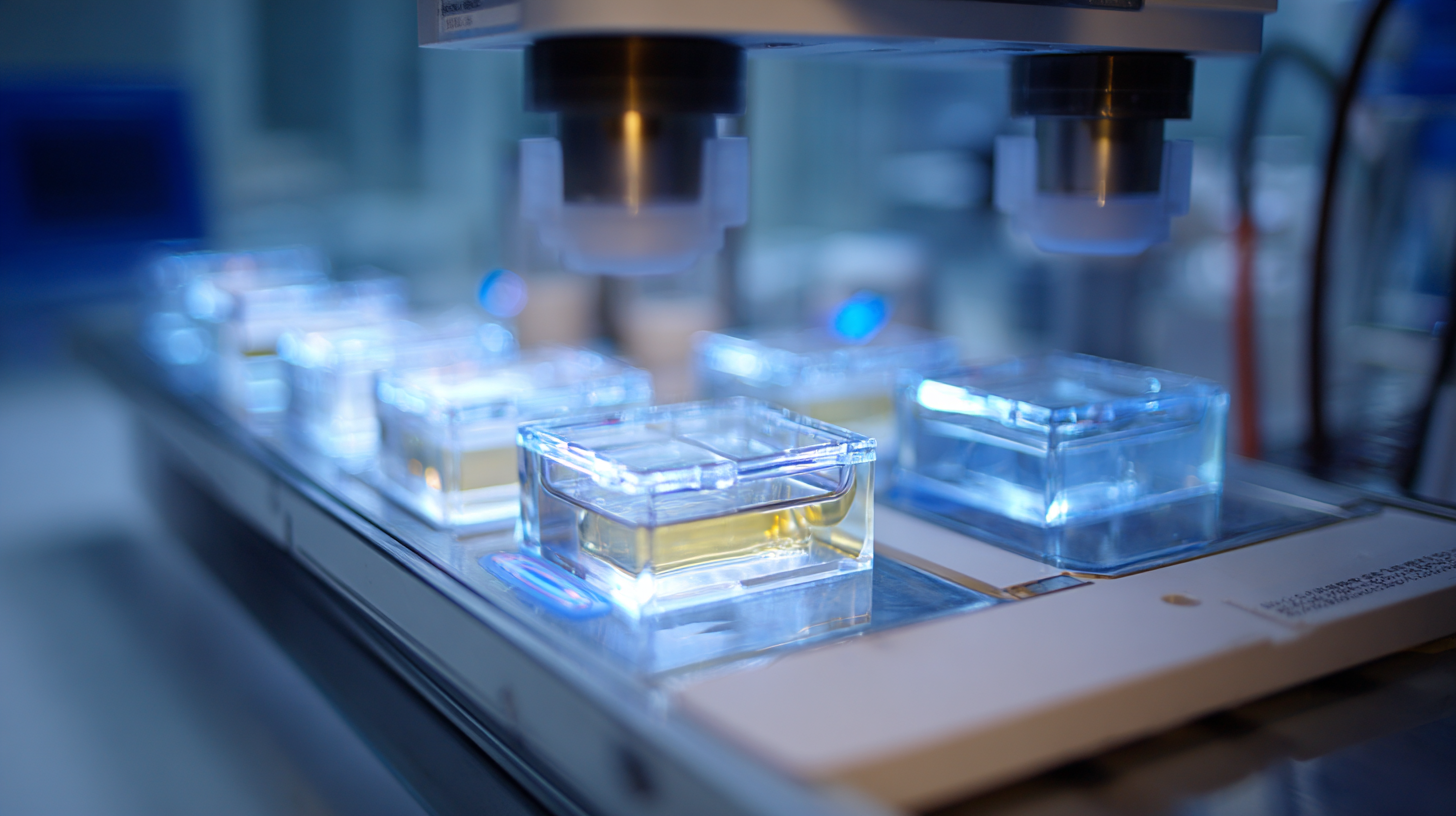

In the realm of laboratory mixing solutions, the efficacy of a Lab PTFE Magnetic Stirrer Bar is paramount for achieving optimal results in various applications. As evidenced by recent industry reports, the demand for efficient and reliable mixing solutions has surged in sectors ranging from pharmaceuticals to chemical engineering. According to a study by MarketsandMarkets, the global laboratory stirrers market is projected to reach USD 2.4 billion by 2025, with a significant driver being the advancement of laboratory equipment technology.

The Lab PTFE Magnetic Stirrer Bar, known for its robust chemical resistance and ability to uniformly mix viscous fluids at varying speeds, plays a critical role in ensuring accuracy and consistency in experimental procedures. Its unique properties not only enhance the efficiency of mixing processes, but also align with the growing emphasis on safety and automation in modern laboratory settings, making it an essential tool for researchers and scientists alike.

PTFE magnetic stirrer bars offer several advantages in various mixing applications, particularly due to their unique chemical properties and performance capabilities. Polytetrafluoroethylene (PTFE) is renowned for its excellent resistance to chemical corrosion, making it an ideal material for use in laboratories and industrial settings where harsh chemicals are common. The non-stick surface of PTFE contributes to efficient mixing processes, as it minimizes residue buildup and facilitates smooth operation over extended periods.

Recent developments in the PTFE sector highlight its growing significance in innovative fields, including robotics. The increasing demand for humanoid robots has attracted investments in PTFE materials, indicating a robust market potential. Additionally, advancements such as the electrospinning process for producing hollow fiber membranes from PTFE underscore the material's versatility beyond traditional applications. These innovations not only improve the performance characteristics of PTFE but also enhance its usability in various engineering domains, solidifying its position as a critical component in modern mixing solutions.

| Feature | Description | Advantages |

|---|---|---|

| Material | PTFE (Polytetrafluoroethylene) | Highly resistant to chemicals and heat |

| Length Options | Various lengths (1-10 cm) | Customizable for different vessel sizes |

| Magnetic Strength | High-performance magnets | Provides efficient stirring without damage |

| Temperature Range | -200°C to 260°C | Suitable for a wide variety of applications |

| Ease of Cleaning | Non-stick surface | Reduces contamination risks |

| Durability | Long-lasting performance | Cost-effective for lab environments |

| Application Areas | Laboratories, pharmaceuticals, and chemical industries | Versatile use across multiple sectors |

When it comes to selecting the right PTFE magnetic stirrer bar for efficient laboratory mixing, it's essential to consider the specific needs of your experiments. The global market for PTFE membranes is projected to grow significantly, from $220.45 million in 2025 to $3.381 billion by 2032, reflecting the increasing demand for high-performance laboratory equipment. Choosing the appropriate magnetic stirrer bar can enhance efficiency and consistency in mixing solutions, which is crucial for achieving accurate and reproducible results in lab settings.

Tips: Before making a selection, evaluate the viscosity and volume of the solutions you'll be mixing. Lighter stirrer bars are ideal for low-viscosity liquids, while heavier bars provide better stirring for thicker solutions. Additionally, consider the size and compatibility of the stirrer bar with your magnetic stirrer unit to ensure optimal performance.

Moreover, opting for PTFE-coated stirrer bars can offer superior chemical resistance and durability when working with aggressive solvents or extreme pH levels. This resilience is vital for maintaining the integrity of experiments and prolonging the lifespan of your equipment. Investing in the right stirring tools not only boosts productivity but also enhances the reliability of your laboratory results.

Operating a high-performance PTFE magnetic stirrer bar can significantly enhance your laboratory's mixing capabilities, making it an essential tool for chemists and researchers. To efficiently use this device, start by ensuring that your work surface is clean and the stirrer's alignment is correct. Next, secure the PTFE stirrer bar within the container, taking care that it is magnetically coupled to the motor beneath. This step is crucial, as the strength of the magnetic field directly impacts the stirring efficiency, which is particularly important when dealing with viscous solutions or complex chemical mixtures.

As you begin mixing, gradually increase the stirring speed to prevent splashing and ensure a homogeneous solution. According to the latest industry reports, proper use of magnetic stirrer bars can effectively reduce mixing times by up to 50% compared to manual methods, allowing for more efficient workflows in a variety of applications, from pharmaceuticals to materials science. It's also noteworthy that advancements in magnetic materials and designs have improved the performance of these stirrers, enhancing their durability and effectiveness in demanding laboratory environments. By following these steps, you can leverage the full potential of PTFE magnetic stirrer bars in your mixing solutions.

When it comes to utilizing PTFE magnetic stirrer bars for effective mixing solutions, common issues often arise that can significantly hinder laboratory performance. One critical concern is stirring bar contamination, which can compromise both the quality of the mix and the integrity of the samples being processed. Recent studies have highlighted that the contamination risk largely stems from the stir bars themselves, as they can adsorb various substances, leading to unintended reactions or the introduction of foreign materials into the solution.

Experts recommend implementing regular cleaning protocols and using high-quality PTFE stir bars specifically designed to resist contamination. Reports indicate that adhering to stringent cleaning and maintenance guidelines can reduce the risk of introducing contaminants by as much as 85%. Additionally, focusing on the choice of stir bar, such as selecting those with a smooth finish and appropriate size for the vessel, plays a significant role in minimizing wear and tear, which can also lead to particulate contamination. By addressing these common troubleshooting issues and employing best practices, laboratories can improve their mixing efficiency and ensure the reliability of their experimental results.

When using a high-performance PTFE magnetic stirrer bar, proper maintenance is crucial for ensuring longevity and optimal performance. Regular cleaning is vital; residues can accumulate and affect the stirring efficiency. According to a study by the American Chemical Society, 85% of equipment failure can be traced back to inadequate maintenance and cleaning practices. To clean your stirrer bar, use a mild detergent and avoid abrasive materials, which can damage the PTFE surface.

Another essential tip is to avoid exposing the stirrer bar to extreme temperatures. PTFE magnetic stirrer bars typically operate efficiently within a specific range, usually between -200°C and 260°C, as stated in the Journal of Materials Science. Exceeding these limits can warp or damage the bar, thus shortening its lifespan. Additionally, ensure that the bar is properly stored when not in use; keeping it in a secure, dry location can prevent contamination and physical damage. By adhering to these maintenance practices, users can maximize the performance and durability of their PTFE magnetic stirrer bars, promoting efficient mixing solutions in their laboratory workflows.