In the world of electronics assembly and repair, precision is paramount, and the tools you use can make all the difference. One such essential tool is PTFE tweezers, known for their high performance and unique properties that cater specifically to the needs of professionals in this field. These tweezers are not only resistant to heat and chemicals but also provide excellent grip and control, ensuring that intricate components can be handled with the utmost care.

As we delve into this guide, we will explore the various features and advantages of high-performance PTFE tweezers, and provide practical tips on how to effectively utilize them in your electronics projects. Whether you are a seasoned technician or a DIY enthusiast, mastering the use of PTFE tweezers can significantly elevate your precision in electronics assembly and repair tasks.

High-performance PTFE tweezers have become an invaluable tool in electronics assembly and repair, owing to their unique properties that enhance precision and efficiency. PTFE, or polytetrafluoroethylene, is known for its non-stick surface, which prevents unwanted residue from adhering to the tweezers. This characteristic not only allows for clean handling of delicate electronic components but also minimizes the risk of contaminating sensitive circuits, ensuring that every assembly or repair task meets stringent quality standards.

High-performance PTFE tweezers have become an invaluable tool in electronics assembly and repair, owing to their unique properties that enhance precision and efficiency. PTFE, or polytetrafluoroethylene, is known for its non-stick surface, which prevents unwanted residue from adhering to the tweezers. This characteristic not only allows for clean handling of delicate electronic components but also minimizes the risk of contaminating sensitive circuits, ensuring that every assembly or repair task meets stringent quality standards.

Furthermore, PTFE tweezers are resistant to heat and chemicals, making them ideal for use in environments where soldering or exposure to various solvents occurs. This thermal stability allows technicians to work confidently without the fear of materials degrading or melting under extreme conditions. The lightweight yet durable nature of PTFE also provides excellent grip and control, enabling operators to execute intricate maneuvers with ease and accuracy. As such, high-performance PTFE tweezers stand out as essential tools that enhance the overall efficiency and reliability of electronic repairs and assembly processes.

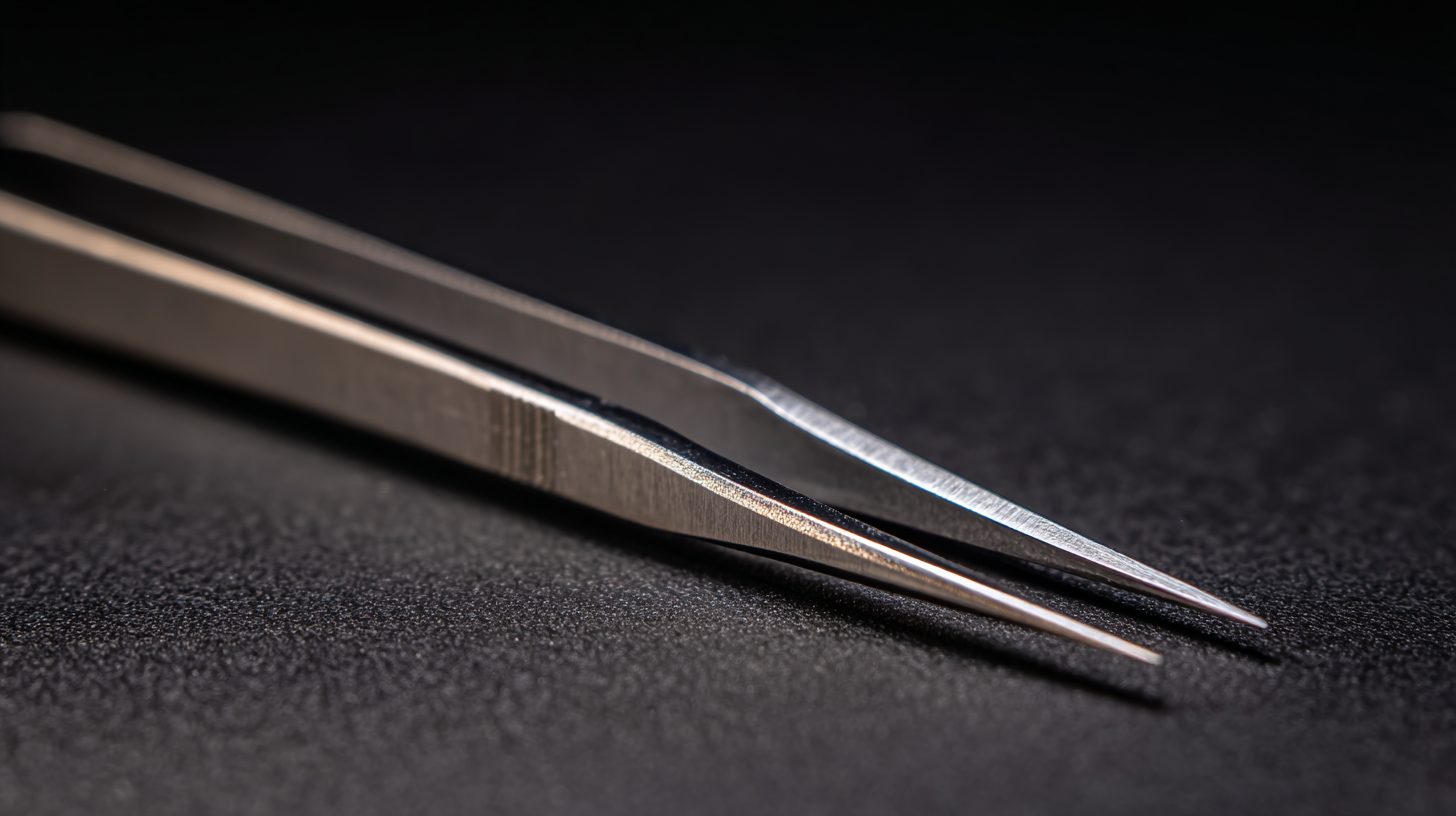

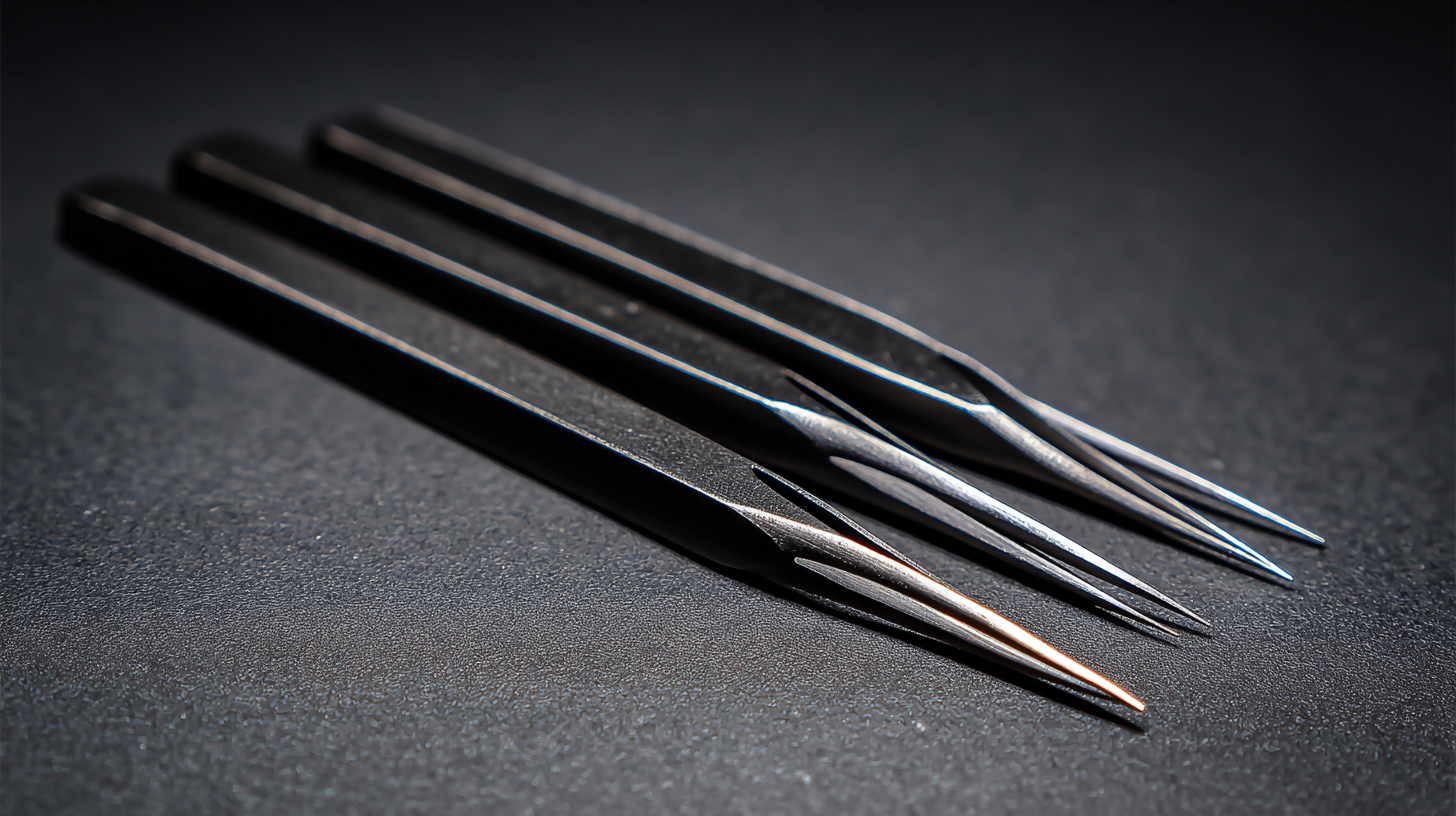

When it comes to electronics assembly and repair, selecting the appropriate PTFE tweezers for specific tasks is crucial for achieving precision and efficiency. PTFE (Polytetrafluoroethylene) tweezers are known for their non-stick properties, heat resistance, and insulating capabilities, making them ideal for handling sensitive components without causing damage. For tasks involving fine electronic components, such as SMT (Surface Mount Technology) placement, fine-tipped PTFE tweezers with a tapered design provide the dexterity needed to maneuver tightly packed parts.

In contrast, for tasks that require gripping larger components or exerting more force, wider or angled PTFE tweezers can be more effective. Additionally, some tasks may involve working in static-sensitive environments, where ESD-safe PTFE tweezers play a significant role in preventing damage to electronic circuits. By understanding the specific requirements of each task, professionals can choose the right type of PTFE tweezers, ensuring optimal performance in electronics assembly and repair while safeguarding delicate components from harm.

PTFE tweezers are indispensable tools in electronics assembly and repair, particularly due to their unique properties that enhance precision and safety. When using PTFE tweezers, one critical technique is to ensure a proper grip on the component. Adjust the pressure applied so that it firmly holds the item without damaging sensitive materials. This delicate balance allows for accurate placement and manipulation of components, reducing the risk of static discharge that can occur with metal tools.

Another effective practice is to maintain a clean working environment. Dust and debris can easily complicate the assembly process, leading to potential errors. Regularly cleaning the PTFE tips with a soft cloth will also enhance their performance and longevity.

Moreover, employing the tweezers at the appropriate angles can provide better access to confined spaces on a circuit board, facilitating easier handling of small components and preventing unintentional shorts. By mastering these techniques, users can significantly improve the efficiency and accuracy of their electronic assembly and repair tasks.

PTFE (Polytetrafluoroethylene) tweezers are indispensable tools in electronics assembly and repair, known for their non-stick properties and chemical resistance. To ensure the longevity of these precision tools, proper maintenance is crucial. Regular cleaning is essential; use isopropyl alcohol or a mild detergent to remove any contaminants after use. Avoid using abrasive cleaners or scrubbers that could scratch the surface of the tweezers. Additionally, it is important to store PTFE tweezers in a protective case or designated area to prevent physical damage and contamination.

According to industry reports, the lifespan of PTFE tweezers can be significantly increased with routine care—often exceeding five years when properly maintained. Beyond cleaning, it is advisable to inspect tweezers regularly for signs of wear or damage, as this can affect their precision and performance. Using these tools in the appropriate environments—avoiding high-temperature settings where PTFE's integrity might be compromised—can further enhance their durability. By following these maintenance tips, electronics professionals can maximize the performance and lifespan of their PTFE tweezers, ensuring they remain an effective tool in any assembly or repair task.

When using tweezers in electronics assembly and repair, avoiding common mistakes is essential to enhance precision and efficiency. One prevalent error is choosing the wrong type of tweezers for the task at hand. According to a recent industry report by IPC, using anti-static PTFE tweezers can reduce the risk of electrostatic discharge (ESD) damage by up to 90%. Selecting tweezers with a suitable tip shape—notably fine or angled tips—can significantly improve grip and accuracy when handling small components.

Another frequent mistake is applying excessive force when picking up delicate parts. This can lead to damaged components or misalignment, which can be costly in electronics manufacturing. A study from Electronics Weekly highlights that improper handling can increase failure rates by 30%. To mitigate this, it's crucial to adopt a gentle touch and consider utilizing tools that provide better control.

**Tips:** Always inspect tweezers for cleanliness and damage before usage, as contaminants can affect the handling of sensitive components. Additionally, investing in a quality set of high-performance PTFE tweezers designed specifically for electronics can greatly enhance your work’s precision and reliability. Always ensure your workspace is static-free to protect sensitive devices during assembly and repair.