In the realm of industrial applications, the selection of sealing materials plays a crucial role in ensuring optimal performance and reliability. One of the standout materials in this context is the Ptfe sealing gasket, renowned for its exceptional resistance to chemicals, high temperatures, and pressures. As industries increasingly face challenging environments that demand dependable sealing solutions, understanding the significance of Ptfe sealing gaskets becomes paramount.

These gaskets not only contribute to the integrity of fluid systems but also enhance the longevity of equipment by preventing leaks and reducing downtime. This article delves into the reasons behind the growing reliance on Ptfe sealing gaskets in various industrial sectors and highlights their unmatched advantages over traditional sealing materials. By exploring the vital role these gaskets play, we aim to underscore their importance in maintaining efficiency and safety in industrial operations.

PTFE sealing gaskets have emerged as a game-changer in various industrial applications, thanks to their remarkable resistance to chemicals, temperature fluctuations, and moisture. According to a recent report by Smithers Pira, the global market for industrial sealing solutions is projected to reach $11.9 billion by 2027, driven primarily by the adoption of high-performance materials like PTFE. The benefits of using PTFE gaskets are multifaceted; they not only enhance sealing performance but also significantly reduce the risk of leaks, which can lead to environmental hazards and costly downtime.

One of the key advantages of PTFE gaskets is their ability to withstand extreme temperatures ranging from -200°C to 260°C without compromising integrity. This makes them ideal for industries such as chemical processing and oil and gas, where temperature and pressure conditions can fluctuate dramatically. Furthermore, PTFE gaskets are non-stick and hydrophobic, which means they can help maintain optimal system performance, reducing the frequency of maintenance and replacements, thereby saving costs in the long run.

Tip: When selecting PTFE gaskets for your application, consider the specific chemical exposure and temperature range. Always ensure that the gasket material is compatible with your operational environment.

Tip: Regular inspections and timely replacements of PTFE gaskets can enhance system efficiency and prevent unexpected leaks, ensuring compliance with environmental regulations and protecting against costly operational disruptions.

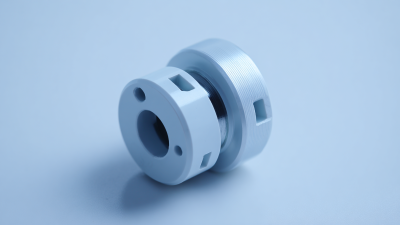

When selecting the right PTFE gasket for your industrial application, one must consider both material properties and operational environment. PTFE gaskets are renowned for their chemical resistance and ability to withstand extreme temperatures, making them ideal for a variety of industries, including hydrogen production, sealing technologies, and electric vehicles. However, the selection process should take into account not just the physical characteristics of the gasket, but also the specific application requirements.

**Tips:** Always ensure that the PTFE gasket you choose is suitable for the fluids and conditions it will encounter. Proper gasket storage is vital; keep gaskets in a clean, dry environment to prevent contamination. Additionally, avoid mishandling, as physical damage can compromise the sealing efficiency and lead to leaks.

With the growing focus on sustainability, it’s essential to assess emerging alternatives to traditional PTFE materials that may pose environmental challenges, including regulations concerning PFAS substances. Understanding these factors will help in making informed decisions that not only meet performance benchmarks but also adhere to regulatory requirements.

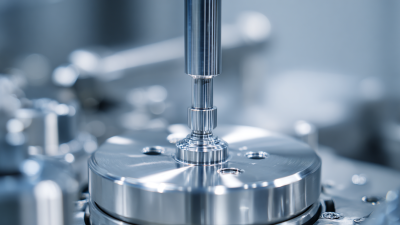

When it comes to ensuring leak-proof seals in various industrial applications, the proper installation of PTFE sealing gaskets is crucial. To begin with, it is essential to choose the right gasket thickness and size to match the flange specifications precisely. A misfit can lead to insufficient sealing and eventually cause operational inefficiencies. Before installation, both the gasket and flange surfaces should be thoroughly cleaned to remove any contaminants or old sealing materials that might compromise the seal's integrity.

During installation, it’s important to apply uniform pressure when tightening the bolts. This can be achieved by following a crisscross pattern, which helps to evenly distribute the load across the gasket surface. Avoid overtightening as it may distort the PTFE material, leading to reduced sealing performance. Furthermore, allowing the gasket to settle after initial installation by revisiting the bolt tension is a best practice that often yields better results and longer-lasting seals.

| Application | Temperature Resistance (°C) | Pressure Resistance (bar) | Chemical Compatibility | Installation Best Practices |

|---|---|---|---|---|

| Oil & Gas | -200 to 260 | 100 | Excellent resistance to hydrocarbons | Ensure a clean surface before installation |

| Food Processing | -50 to 220 | 60 | Compatible with various food acids | Use FDA-approved PTFE for safety |

| Chemical Processing | -200 to 260 | 50 | Resistant to strong acids and bases | Ensure proper alignment during installation |

| Pharmaceuticals | -50 to 200 | 40 | High compatibility with various compounds | Follow sterilization procedures post-installation |

PTFE gaskets are crucial components in various industrial applications given their excellent chemical resistance and ability to withstand high temperatures. To maximize their longevity and ensure optimal performance, proper maintenance is essential. Regular inspections are key; check for signs of wear and tear, such as cracks or deformation, which can compromise the sealing capability.

Another vital tip is to apply the correct torque during installation. Over-tightening can lead to deformation, while under-tightening may not provide a proper seal. It's advisable to follow manufacturer guidelines for torque specifications. Additionally, keeping a clean working environment helps prevent contaminants from damaging the gasket during the sealing process.

The growing importance of sealing solutions is reflected in the increasing demand across various sectors. For instance, the Radial Oil Seals market is projected to reach USD 4,500 million by 2035, with a CAGR of 3.2%. This indicates a robust need for reliable sealing materials such as PTFE gaskets, underscoring their significance in maintaining equipment efficiency and preventing costly leaks. Investing time in gasket maintenance not only extends their lifespan but also enhances overall machinery performance.

PTFE sealing gaskets are crucial in various industrial applications due to their excellent chemical resistance and thermal stability. However, challenges such as improper installation, compatibility with aggressive media, and wear over time can significantly impact their performance. According to a recent industry report by the Institute of Sealing Technology, approximately 30% of gasket failures can be attributed to installation errors, underscoring the importance of proper training for technicians.

To mitigate these challenges, it is essential to select the right type of PTFE gasket for specific applications. For instance, using graphite-filled PTFE gaskets can enhance the sealing capability under extreme pressure and temperature conditions. Additionally, regular maintenance checks can help identify wear patterns early, allowing for timely replacements.

**Tips:** Always ensure that the gasket is properly aligned and torque settings are followed as per equipment specifications. Utilizing a gasket with a low compression set can also significantly reduce the likelihood of leakage over time. Lastly, keep an eye on temperature fluctuations and the chemical nature of the substances being sealed, as these can lead to premature gasket failure if not appropriately managed.