In the realm of laboratory equipment, the importance of effective mixing cannot be overstated. According to a recent market research report by Grand View Research, the global laboratory stirring devices market is projected to reach USD 1.12 billion by 2025, highlighting a growing demand for high-quality mixing solutions. Central to this innovation are PTFE stir bars, which offer unparalleled resistance to chemicals and high temperatures, making them an essential tool for precise and reliable mixing.

Leveraging advanced manufacturing techniques, "中国制造,全球共享,品质值得信赖" signifies a commitment to quality, ensuring that these PTFE stir bars meet rigorous international standards. As laboratories increasingly seek innovative and dependable solutions, the use of PTFE stir bars not only enhances mixing efficiency but also supports the integrity of various scientific processes.

Leveraging advanced manufacturing techniques, "中国制造,全球共享,品质值得信赖" signifies a commitment to quality, ensuring that these PTFE stir bars meet rigorous international standards. As laboratories increasingly seek innovative and dependable solutions, the use of PTFE stir bars not only enhances mixing efficiency but also supports the integrity of various scientific processes.

As we look towards 2025, the landscape of mixing technology is set to change significantly. A recent report by MarketsandMarkets projects that the global mixing equipment market will grow from $5.89 billion in 2020 to $8.02 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.4%. This growth is fueled by the increasing demand for high-quality mixing in industries such as pharmaceuticals, food and beverages, and chemicals. With such a strong upward trajectory, innovations in mixing technology, particularly the use of advanced PTFE stir bars, are poised to play a crucial role.

One of the key innovations in this space is the development of PTFE stir bars that enhance mixing efficiency by minimizing stickiness and improving temperature resistance. According to research published in the Journal of Chemical Engineering, the use of PTFE materials can increase the mixing speed by up to 25% compared to traditional materials. Furthermore, as manufacturers continue to adopt automation and digital solutions, integrating smart sensors into mixing equipment will allow for real-time monitoring and adjustments, ensuring optimal performance. As these trends unfold, businesses that prioritize innovative mixing solutions will be better positioned to meet regulatory demands and improve product consistency.

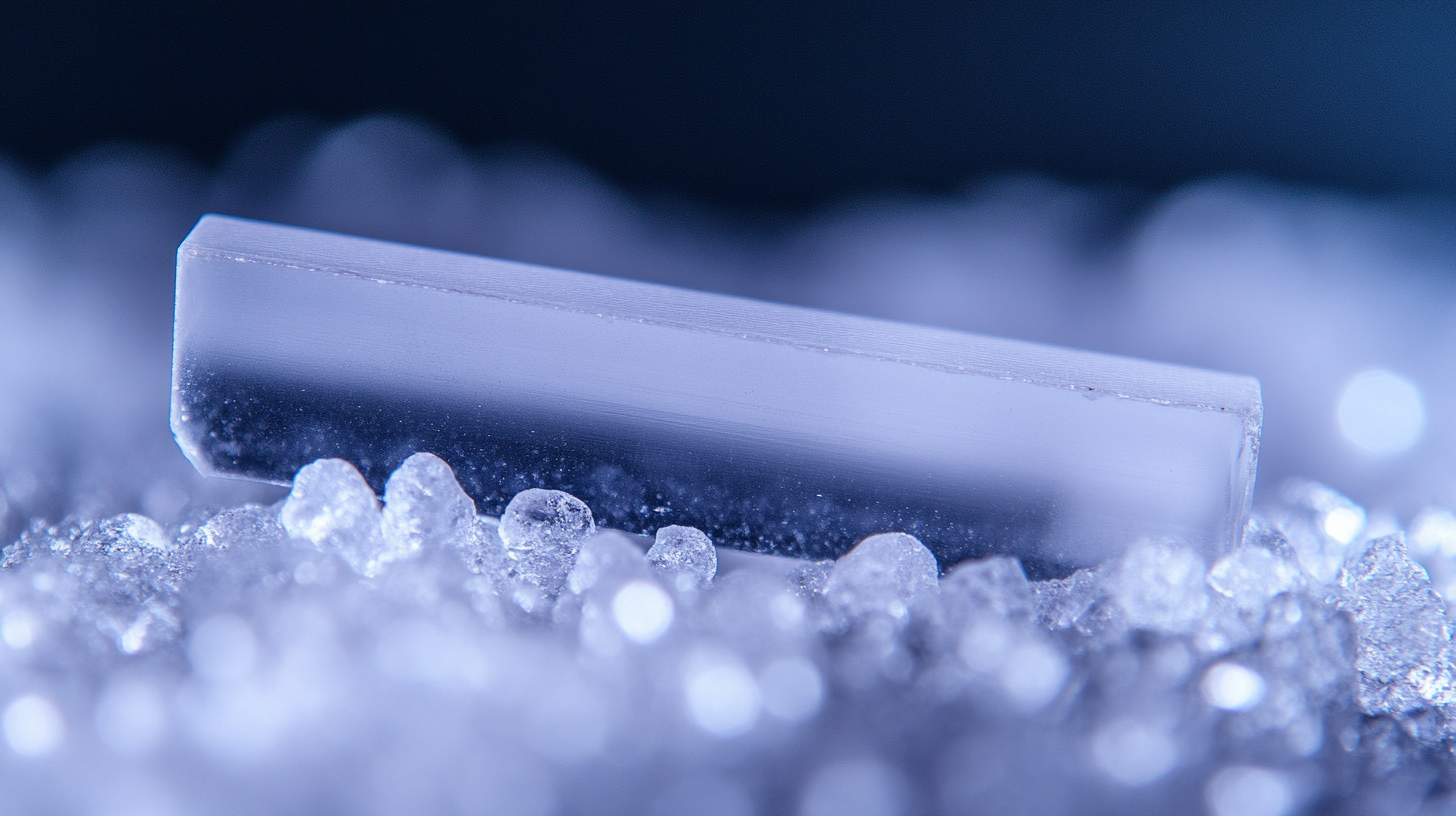

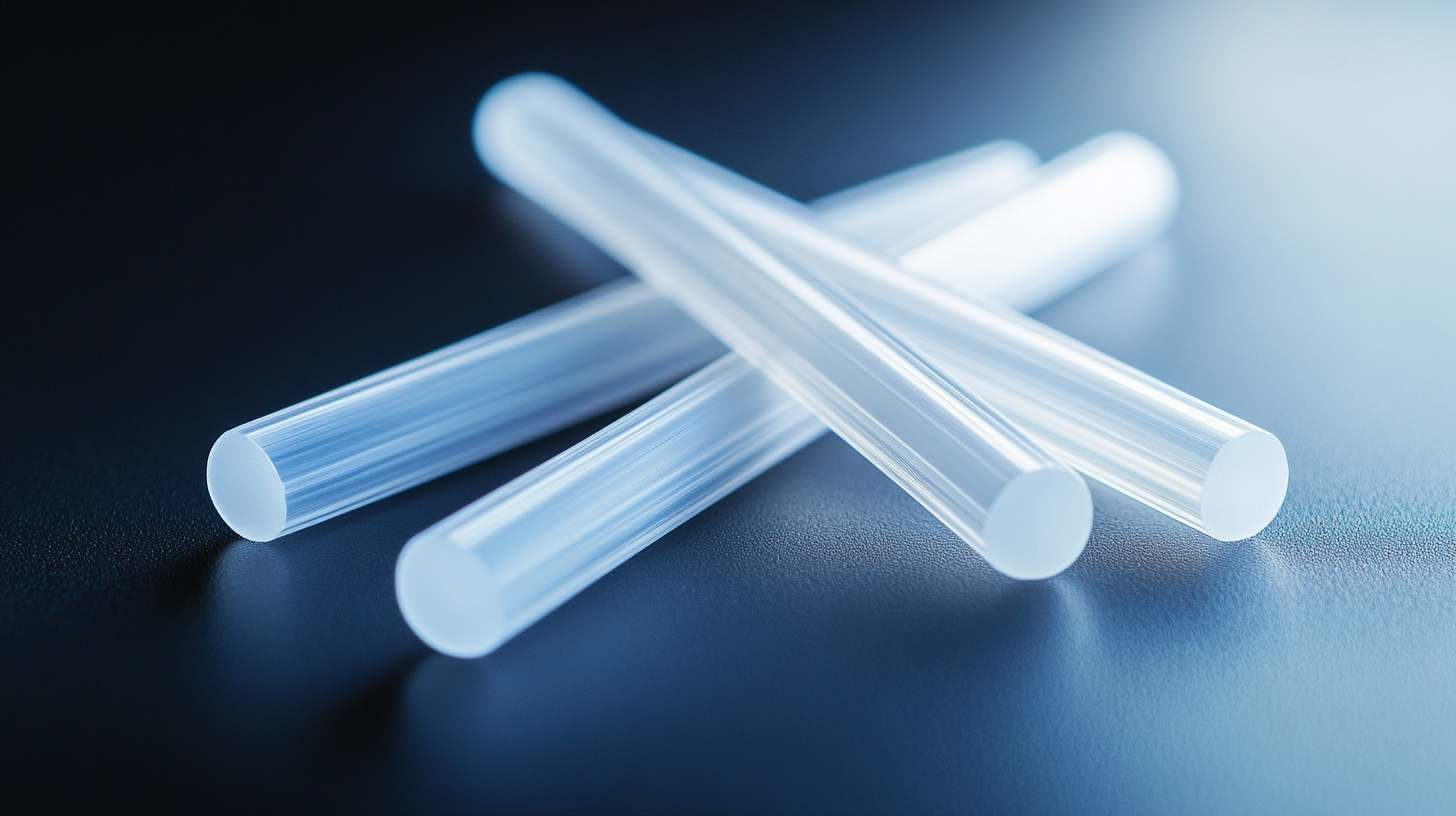

In the realm of laboratory mixing, PTFE stir bars have emerged as a revolutionary solution, significantly enhancing both performance and efficiency. These stir bars, composed of polytetrafluoroethylene (PTFE), offer remarkable chemical resistance and durability. This makes them ideal for applications involving aggressive solvents and reactive reagents. Unlike traditional stir bars, PTFE stir bars minimize contamination risks, ensuring the integrity of the mixed solution remains intact. Their non-stick properties also facilitate easy cleaning, saving valuable time in busy laboratory environments.

Advancements in PTFE stir bar technology have led to the development of specialized designs that optimize mixing efficiency. Features such as enhanced magnetic properties and unique shapes have been introduced to improve fluid dynamics and ensure uniform mixing. Furthermore, these innovations allow for the stirring of higher viscosity liquids, broadening the scope of applications in research and industrial settings. By adopting these cutting-edge PTFE stir bars, laboratories can achieve superior mixing results while fostering a safer and more productive working environment.

| Dimension | Standard Type | Material | Efficiency Rating | Applications |

|---|---|---|---|---|

| 10 mm | Standard Stir Bar | PTFE Coated | High | Laboratory Mixing |

| 20 mm | Magnetic Stir Bar | PTFE | Very High | Chemical Processes |

| 30 mm | Custom Stir Bar | Glass-Fiber Reinforced PTFE | Medium | Biochemical Applications |

| 15 mm | High-Viscosity Stir Bar | PTFE + Special Additives | High | Food Industry |

When it comes to mixing in laboratory settings or industrial applications, the choice of stir bar material can significantly affect the outcome of the process. PTFE (Polytetrafluoroethylene) stir bars have gained popularity due to their unique properties that set them apart from traditional materials. One of the primary benefits of PTFE is its exceptional chemical resistance, making it suitable for mixing corrosive or reactive substances without contaminating the samples. This robustness means that researchers and manufacturers can rely on PTFE stir bars for a wide range of applications, from organic chemistry to pharmaceuticals.

Another advantage of PTFE stir bars is their low friction surface, which allows for smooth and efficient mixing. This characteristic not only enhances the mixing performance but also reduces wear on equipment, prolonging the lifespan of both the stir bar and the stirring system. Additionally, PTFE is non-stick, which minimizes the risk of material adhering to the stir bar, ensuring a clean and efficient mixing process. In a comparative analysis with other materials like glass or metal, PTFE clearly demonstrates its superiority in terms of versatility, durability, and safety, making it the preferred choice for innovative mixing solutions in various industries.

In recent years, the push for sustainability in laboratory practices has led to significant advancements in the production of PTFE stir bars. Traditional manufacturing methods often contribute to environmental harm, but innovative techniques are emerging that prioritize eco-friendliness. According to a report from the Research Institute of Environmental Sciences, approximately 90% of laboratory consumables end up in landfills. By utilizing renewable materials and reducing plastic waste, modern stir bar production seeks to address this pressing issue while maintaining performance.

One effective way laboratories can enhance their sustainability is by opting for stir bars made from recycled PTFE. These options not only minimize the carbon footprint but also retain the durability and chemical resistance necessary for effective mixing. Additionally, the implementation of energy-efficient manufacturing processes can reduce emissions significantly; a recent study indicated that adopting such technologies could lower greenhouse gas emissions by up to 40% in the production of laboratory supplies.

Tips for Eco-Friendly Mixing Solutions:

1. Choose stir bars produced with eco-friendly methods, ensuring they meet high-performance standards.

2. Consider reusing stir bars wherever possible, cleaning them thoroughly to extend their lifespan.

3. Explore suppliers that offer recycling programs or take-back schemes for used stir bars, promoting a circular economy in laboratory settings.

When it comes to maximizing laboratory efficiency, the use of PTFE stir bars can revolutionize the mixing process. One key practice is to select the right stir bar for your specific application. PTFE stir bars offer advantages such as chemical resistance and durability, making them ideal for working with a variety of solvents and corrosive materials. Utilizing stir bars that are appropriately sized and shaped for your beaker or flask will not only enhance mixing but also reduce the time and energy spent on each experiment.

Another best practice is to optimize stirring speed and duration. Gradually increasing the stirring speed helps to prevent splashing and ensures a consistent mixing environment. It’s also essential to monitor the viscosity of the solution; a thick solution may require slower speeds to achieve proper mixing without damaging the stir bar or the container. Furthermore, ensure your stir bars are clean and free from residue to maintain their effectiveness. Adopting these strategies will lead to improved results in your experiments and a noticeable increase in your laboratory's overall productivity.