In modern laboratories, the efficiency of stirring processes is paramount to achieving precise and reproducible results. The Magnetic PTFE Stir Bar has emerged as an indispensable tool, particularly in fields such as chemistry and biochemistry, where optimal mixing of solutions is crucial. According to a recent report by Research and Markets, the global laboratory stirrers market is expected to grow by 5.4% annually, indicating an increasing reliance on effective mixing solutions. However, many laboratories may overlook the critical factors influencing the performance of their Magnetic PTFE Stir Bars, leading to suboptimal mixing and prolonged experiment durations. By understanding the key optimization techniques for these stir bars, laboratories can significantly enhance their operational efficiency and improve the consistency of their experimental outcomes. In this guide, we will explore actionable strategies to maximize the effectiveness of Magnetic PTFE Stir Bars, ensuring that your laboratory operations meet the highest standards of performance.

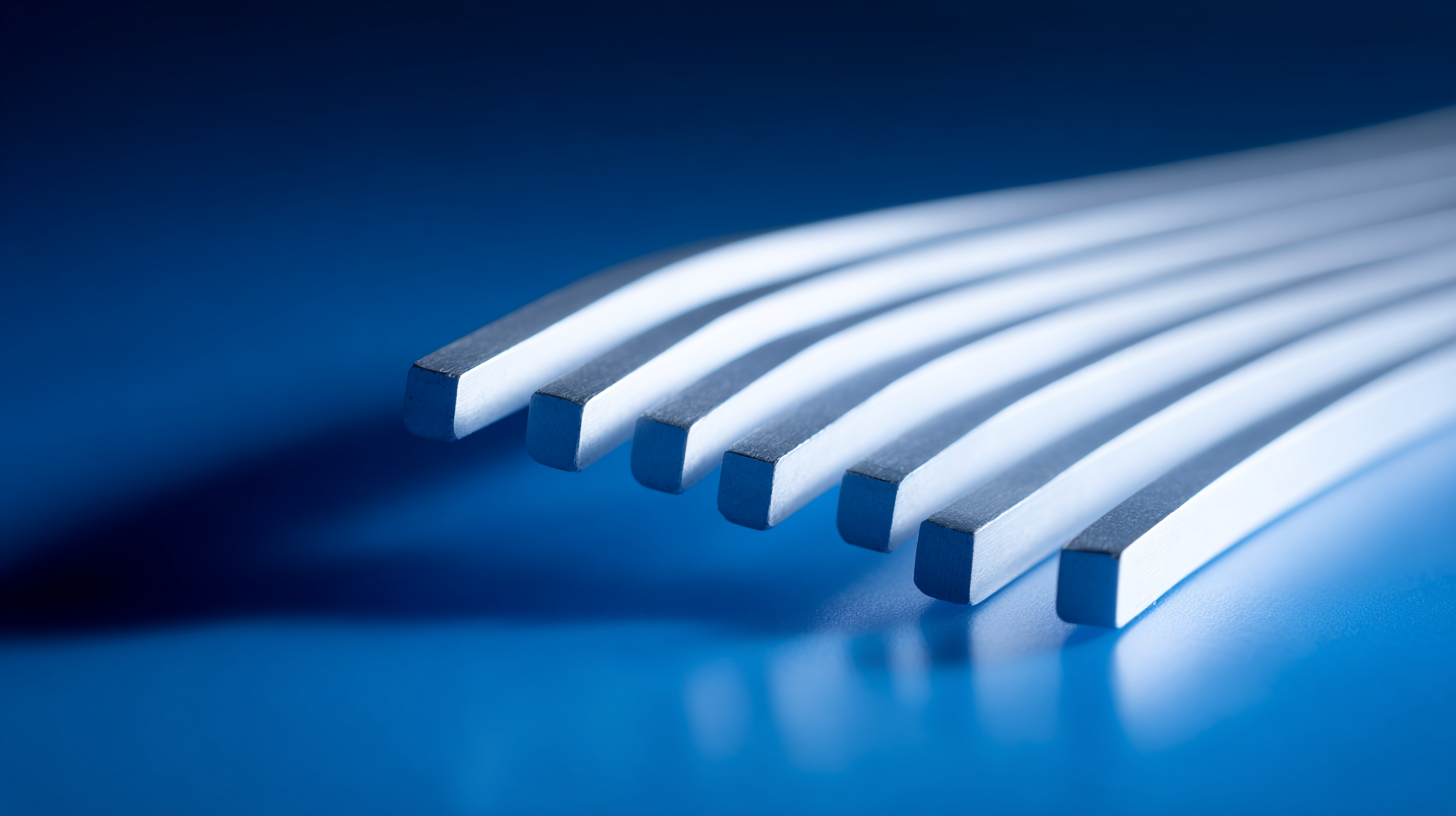

Magnetic PTFE stir bars play a crucial role in laboratory work, particularly in ensuring homogenous mixing of solutions. Their non-stick and chemical-resistant properties make them ideal for various applications, including pharmaceuticals, chemistry, and biological research. Understanding the importance of these stir bars allows researchers to select the right equipment and optimize their experiments for enhanced results.

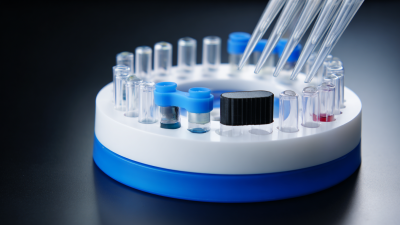

When using magnetic PTFE stir bars, several tips can enhance efficiency. First, choose the appropriate size and shape of the stir bar based on the volume and viscosity of the solution being mixed. A larger stir bar may be required for viscous liquids to achieve effective mixing. Additionally, ensure that the stir bar is positioned correctly within the container; it should not touch the sides to prevent uneven stirring.

Another important aspect is the speed of stirring. Start at a lower speed and gradually increase to avoid splashing and promote uniform mixing. Also, regularly check the stir bar for wear and tear, as damaged stir bars can lead to contamination and inconsistent results. By implementing these practices, laboratories can maximize the functionality of their magnetic PTFE stir bars, leading to more reliable and accurate outcomes in their research.

The performance of magnetic PTFE stir bars is influenced by several key factors that can significantly enhance laboratory efficiency. One primary aspect is the material composition of the stir bar itself. High-quality PTFE, known for its chemical resistance and low friction properties, ensures a smoother stirring process, reducing wear and tear while increasing longevity. Additionally, the magnet’s strength is crucial; a stronger magnet ensures reliable mixing at various viscosities and prevents the stir bar from disengaging during operation, thus maintaining consistent results in experiments.

The performance of magnetic PTFE stir bars is influenced by several key factors that can significantly enhance laboratory efficiency. One primary aspect is the material composition of the stir bar itself. High-quality PTFE, known for its chemical resistance and low friction properties, ensures a smoother stirring process, reducing wear and tear while increasing longevity. Additionally, the magnet’s strength is crucial; a stronger magnet ensures reliable mixing at various viscosities and prevents the stir bar from disengaging during operation, thus maintaining consistent results in experiments.

Another vital factor is the design of the stir bar. Shapes and sizes tailored to specific applications can optimize mixing efficiency. For instance, a longer stir bar may be more effective in larger volumes, while a stir bar with unique geometries can enhance turbulence, resulting in improved homogeneity of the solution. Lastly, selecting the right RPM settings for the stir bar maximizes performance. Understanding the dynamics of fluid motion can help researchers fine-tune their stirring practices, ultimately leading to more effective laboratory procedures and reliable data.

Selecting the right magnetic PTFE stir bar is crucial for achieving optimal laboratory efficiency. The first step in this process is to consider the size and shape of the stir bar. Commonly, stir bars come in various lengths and designs, such as oval or cylindrical shapes. Choosing a stir bar that fits the dimensions of your container will ensure effective mixing. Additionally, the stir bar should have a suitable weight to generate sufficient agitation without risking damage to fragile glassware.

Another important factor is the chemical compatibility of the PTFE material with the substances being mixed. PTFE is known for its excellent resistance to chemicals, but it's essential to verify that the specific PTFE stir bar can withstand the reagents used in your experiments. Moreover, pay attention to the stir bar's magnetic strength, as a robust magnet will enhance the mixing performance and reliability during operation. By carefully considering these factors, you can select a magnetic PTFE stir bar that maximizes laboratory efficiency and supports reproducible results in your experiments.

This chart illustrates key performance metrics associated with optimizing Magnetic PTFE stir bars, including size, stirring speed, chemical compatibility, cost, and durability. Each factor plays a vital role in achieving maximum laboratory efficiency.

Maintaining and cleaning your magnetic PTFE stir bar is crucial for ensuring optimal performance in laboratory settings. Regular maintenance prevents contaminants from affecting your experiments, thus enhancing the accuracy of your results. To begin, after each use, rinse the stir bar under running water to remove any residual substances. This step is essential, especially when working with viscous or sticky materials. For thorough cleaning, a gentle soap solution can be employed, followed by rinsing with deionized water to eliminate any soap residues that might interfere with future reactions.

In addition to routine cleaning, it's important to inspect the stir bar for wear and tear. Signs of damage, such as chips or scratches, can compromise its effectiveness and lead to contamination. If any defects are observed, replace the stir bar to maintain high standards in your work. Storing the stir bars properly is also vital; they should be kept in a designated space away from harsh chemicals and physical impacts to prolong their lifespan. By incorporating these cleaning and maintenance techniques, you can maximize the efficiency of your experiments and ensure consistent results in your laboratory.

| Parameter | Optimal Value | Cleaning Frequency | Maintenance Tips |

|---|---|---|---|

| Length (cm) | 5-10 | After every use | Rinse with distilled water |

| Magnet Strength | Strong (≥ 2000 Gauss) | Weekly | Inspect for wear and demagnetization |

| PTFE Thickness (mm) | 2-3 | Monthly | Avoid extreme temperatures |

| Stirring Speed (rpm) | 100-200 | As needed | Adjust based on viscosity |

| Chemical Compatibility | Acids, Bases, Solvents | After each experiment | Use appropriate solvents for cleaning |

To optimize stirring conditions for enhanced reaction efficiency, it is essential to focus on the characteristics of the PTFE stir bar used in laboratory settings. The design of the stir bar, including its shape, size, and magnetic properties, directly influences the mixing dynamics within the reaction vessel. Adjusting these factors to match the viscosity and requirements of the solution can lead to improved mass transfer rates, reducing reaction times and increasing the overall yield.

Recent advancements in biotechnological processes, such as enzymatic degradation and high-value biological transformations, underscore the importance of optimized stirring conditions in facilitating complex reactions. For instance, the innovative approaches to PET recycling through enzymatic methods demonstrate how precise control over stirring can enhance the efficiency of substrate interactions, ultimately leading to more effective product recovery. Therefore, by refining the stirring parameters and ensuring a well-tuned PTFE stir bar, researchers can significantly boost laboratory efficiency and achieve superior outcomes in their experiments.