Ptfe Coated Magnetic has gained significant traction in various industries due to its unique properties. According to a recent market report, the demand for PTFE-coated materials is expected to rise by 7% annually. This growth is driven by the industry's need for durable and resistant solutions. PTFE, or polytetrafluoroethylene, offers excellent chemical resistance and low friction, making it ideal for coatings.

In manufacturing, Ptfe Coated Magnetic is utilized to enhance the performance of magnets. The coating adds protection and ensures longevity. As industries focus on sustainability, this material serves as an environmentally friendly option. However, challenges remain. Not all applications can leverage the benefits of PTFE coatings. The effectiveness of the coating can vary, leading to inconsistent results.

Research indicates that a significant percentage of companies still underestimate the advantages of Ptfe Coated Magnetic. This gap can hinder innovation and growth within sectors that rely on magnetic applications. Awareness and education on this material are crucial for maximizing its potential. As the industry evolves, the integration of Ptfe Coated Magnetic may redefine performance standards.

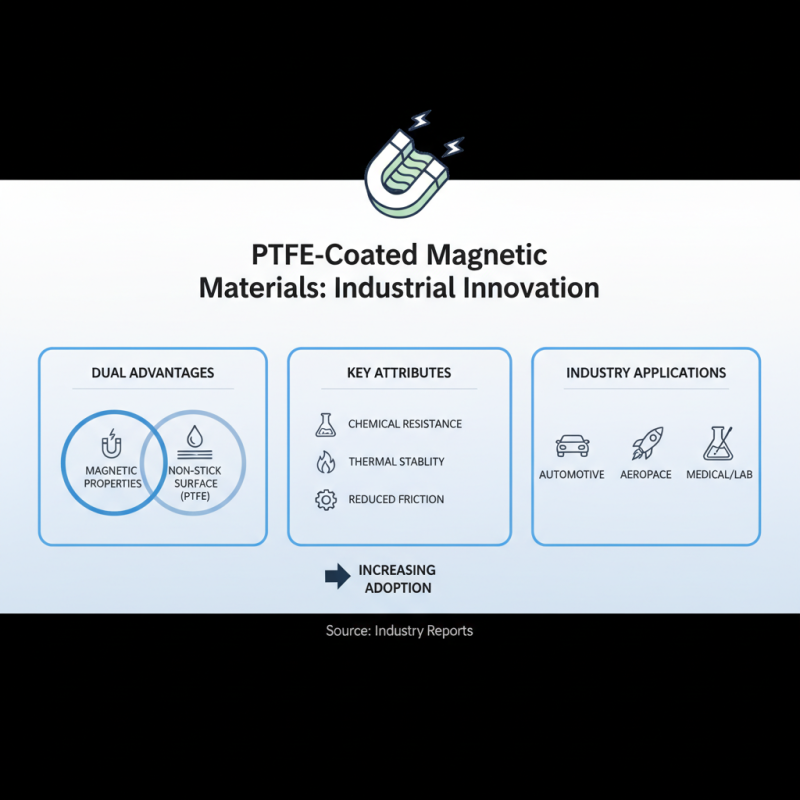

PTFE coated magnetic material is gaining attention in various industries. This unique combination offers both magnetic properties and a non-stick surface. The coating, made from polytetrafluoroethylene (PTFE), provides excellent chemical resistance and thermal stability. Industries like automotive and aerospace are increasingly utilizing these materials.

One significant advantage of PTFE coated magnetic materials is their durability. According to a recent industry report, these materials can withstand extreme temperatures, ranging from -70°C to 260°C. The non-stick surface makes them easier to clean and maintain. However, challenges exist. The adhesion between PTFE and magnetic substrates can sometimes be less reliable. This requires careful formulation and processing to ensure optimal performance.

Applications vary widely. PTFE coated magnets are used in sensors, robotics, and medical devices. They aid in reducing friction and wear, enhancing overall efficiency. Yet, the market is still maturing. Companies must invest in research and development to overcome current limitations. As demand grows for high-performance materials, the potential of PTFE coated magnetic materials remains significant.

PTFE, or polytetrafluoroethylene, is known for its unique properties. It is a non-stick material often found in various applications. This coating has excellent chemical resistance. It stands up well against corrosive substances. PTFE coatings are also non-reactive, ensuring safe use in various environments.

This coating offers a low friction surface, promoting smooth operation. It protects the underlying materials from wear and tear. When used in magnetic applications, PTFE can prevent magnet degradation. This is essential for maintaining efficiency and durability. The coating can withstand a wide range of temperatures, enhancing its versatility.

Tips: Ensure proper surface preparation before applying PTFE. A clean surface leads to better adhesion and performance. Always consider the operational environment when selecting coatings. High temperatures can impact the effectiveness of PTFE. Regularly inspect coated items for signs of wear. This can help catch potential issues before they escalate.

PTFE coated magnetic materials are gaining traction across various industries. Their non-stick properties make them ideal for equipment requiring smooth operation. In the food sector, these materials are often used in conveyor systems. This ensures easier cleaning and reduces contamination risks.

In the chemical industry, PTFE’s resistance to harsh substances is invaluable. Tanks and pipelines benefit from the coating, as it prevents corrosion and extends service life. Many companies report fewer maintenance issues when using coated components. However, the initial investment can be higher, leading to hesitation in adoption.

The electronics sector also utilizes PTFE coated magnetic components. They are used in manufacturing circuit boards and other electronics. The coating reduces friction and minimizes wear. Yet, the performance can vary by environmental conditions. Companies must assess their specific needs carefully.

PTFE coated magnetic materials are gaining significant attention in various industries. Their unique properties provide notable advantages over traditional magnetic materials. One major benefit is their chemical resistance. According to a recent industry report, PTFE can withstand a wide range of chemicals, making it ideal for applications in corrosive environments. This durability leads to longer maintenance cycles and reduced costs over time.

Another advantage is the non-stick nature of PTFE coatings. This characteristic minimizes the friction between components, leading to less wear. A study indicated that using PTFE can reduce friction by up to 75%. This reduction can improve the efficiency of machinery, leading to better performance and energy savings.

Tip: Always assess the environment in which the magnetic material will be used. The operational temperature and chemical exposure can dramatically affect performance and longevity.

Moreover, PTFE coated magnetic materials are lightweight, which can simplify installation and reduce structural support needs. They may still face challenges in extreme temperatures and high-frequency applications. Careful consideration is crucial when choosing materials for specific conditions.

Tip: Experiment with small batches to observe performance before full-scale implementation. Such trials provide valuable insights and can highlight potential issues.

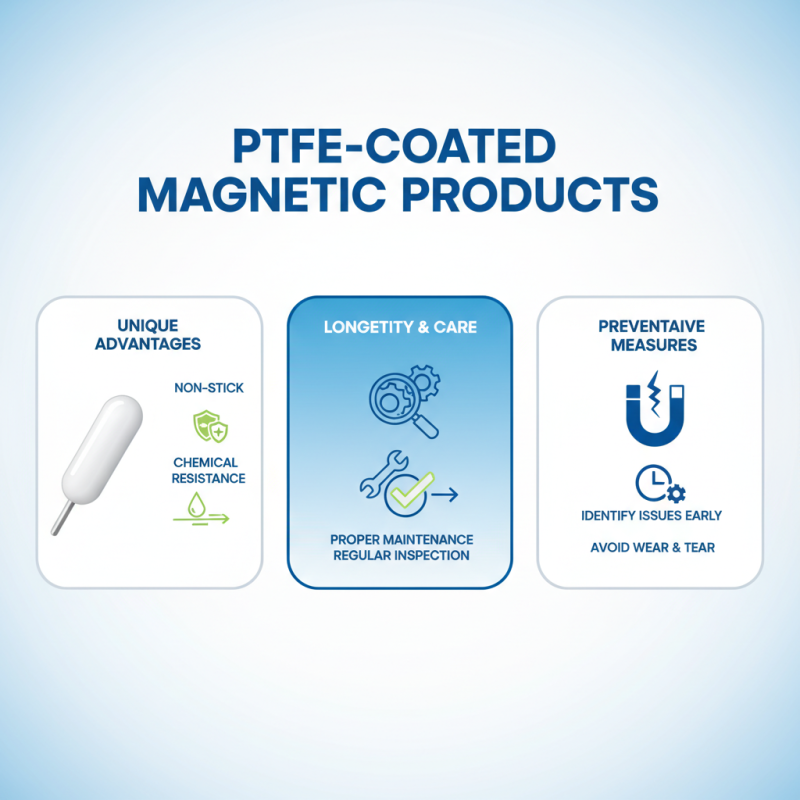

PTFE coated magnetic products offer unique advantages in various applications. They are known for their non-stick properties and resistance to chemicals. However, proper maintenance is essential to ensure longevity. Regularly inspect these products for wear and tear. It helps to identify issues before they worsen.

Cleaning PTFE coated items requires gentle methods. Harsh abrasives can damage the coating. A soft cloth with warm soapy water works well. Rinse thoroughly to avoid residue build-up. Sometimes stubborn stains may linger. In those cases, a mixture of vinegar and water can be effective.

Storage also plays a crucial role. Avoid stacking heavy items on top of PTFE coated products. This can compromise their integrity. Keep them in a cool, dry place. It minimizes exposure to moisture, which can weaken the coating over time. In essence, consistent care can lead to better performance and durability of these magnetic tools.