A PTFE coated magnetic stir bar is a vital tool in laboratories. These stir bars assist in mixing liquids evenly without contamination. The PTFE coating gives them unique properties. It is chemical resistant and easy to clean. These bars have a magnetic core that enables them to spin rapidly in a stirred solution.

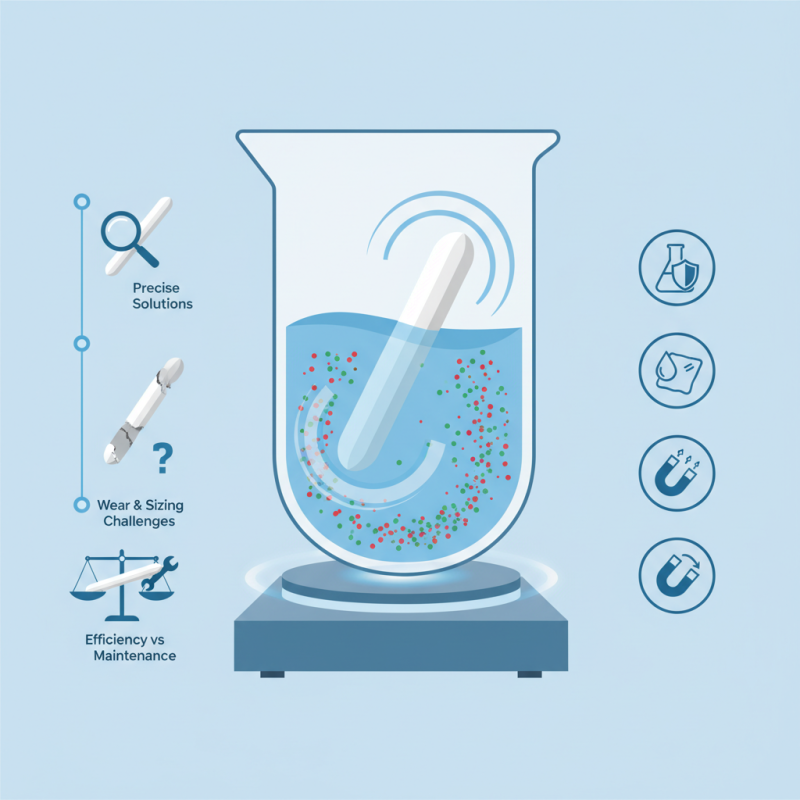

Using a PTFE coated magnetic stir bar can enhance many experiments. They help achieve precise solutions, which is crucial in various fields. However, there are challenges. Over time, the coating can wear off, affecting performance. Finding the right size and shape for specific applications can also be tricky.

Choosing to incorporate a PTFE coated magnetic stir bar should be a well-thought decision. While they offer efficiency, users must consider their specific needs. Proper maintenance is key to longevity. Balancing these factors allows for successful experimentation in different settings.

PTFE, or polytetrafluoroethylene, is a high-performance polymer known for its excellent chemical resistance. This property makes it ideal for use in lab settings, especially where corrosive substances are involved. PTFE’s non-stick surface minimizes residue buildup on stirring bars. This can lead to more accurate results in experiments. According to the Journal of Material Science, PTFE can withstand temperatures ranging from -260°C to 260°C. This wide thermal stability is crucial for various laboratory conditions.

The smooth surface of PTFE-coated magnetic stir bars reduces friction during mixing. This feature helps in minimizing wear and tear, prolonging the life of the stir bar. When looking at industry reports, it’s noted that PTFE’s unique properties can enhance the efficiency of stirring processes. However, not all PTFE-coated bars are created equal. Some may have less effective bonding, leading to chipping or peeling over time. Researchers have reported that lower-quality coatings often compromise the reliability of experiments.

It’s also important to understand that while PTFE is effective, it is not invulnerable. High-speed stirring can sometimes generate heat, risking structural integrity. Evaluating the conditions of use remains essential. Experimental setups must consider the limitations of PTFE. Having a critical eye on PTFE-coated products can save time and resources in the long run.

Magnetic stir bars are essential tools in laboratories. They enable efficient mixing of liquids without physical contact. The bars consist of a magnet encased in a protective coating. This design allows for smooth movement and thorough blending of solutions.

A PTFE-coated magnetic stir bar is particularly useful. PTFE, or polytetrafluoroethylene, is a non-stick material. It withstands harsh chemicals and high temperatures, making it ideal for laboratory settings. When placed in a container with a magnetic stirrer, the stir bar rotates and creates turbulence. This action promotes uniform mixing and helps achieve desired reactions.

Tips: Always choose a stir bar appropriate for your container size. A bar that's too large can cause splashing. A too-small bar may not mix effectively.

Handling the stir bar can be tricky. Dropping it might damage the coating. Inspect it regularly for wear and tear. A damaged bar can contaminate your solution. Remember, a clean working environment ensures better results.

PTFE (Polytetrafluoroethylene) coated magnetic stir bars are essential tools in laboratories. These stir bars are designed to facilitate stirring in a variety of solutions, including corrosive materials. The PTFE coating provides several advantages that enhance their performance.

One major benefit is chemical resistance. PTFE is known for its ability to withstand harsh chemicals. According to a report by the American Chemical Society, PTFE can resist temperatures up to 260°C and various acids. This quality makes PTFE coated stir bars ideal for applications in pharmaceuticals and chemistry research. Additionally, PTFE's non-stick surface allows for easy cleaning, reducing downtime between experiments.

**Tip:** Always inspect your stir bars before use. Look for signs of wear on the PTFE coating. A damaged coating can lead to contamination of your samples.

Another advantage is the reduced friction during stirring. The smooth surface of PTFE minimizes drag, allowing for efficient mixing. Studies suggest that stir bars coated with PTFE can improve mixing efficiency by up to 30% compared to uncoated options. However, the performance can be impacted if the stir bar is too small for the container size. In such cases, it may not generate enough turbulence.

**Tip:** Ensure the stir bar is the right size for your flask. An improperly sized stir bar can lead to ineffective mixing and wasted materials.

PTFE coated magnetic stir bars are essential in many laboratory settings. Their resistance to chemicals makes them ideal for various applications. In pharmaceutical labs, these stir bars help ensure uniform mixing of compounds, preventing contamination. According to a recent industry report, 70% of labs prefer PTFE coatings for their durability and non-reactivity with solvents.

In the educational sector, PTFE coated stir bars offer reliable performance in chemistry experiments. They can withstand high temperatures without degrading. However, improper handling can lead to wear and chip formation. Researchers often report that maintaining the integrity of stir bars is crucial for achieving accurate results.

Tips: Always inspect stir bars for any signs of damage before use. Clean them properly after each experiment to prolong their lifespan. Pay attention to the size and shape of the stir bar to match your reaction vessel; an ill-fitting stir bar can lead to inefficient mixing.

| Feature | Description | Applications |

|---|---|---|

| Material | PTFE (Polytetrafluoroethylene) Coating | Chemical resistance in various solvents |

| Stirring Mechanism | Magnetic field drives the stir bar | Used in stirring solutions uniformly |

| Temperature Range | -200°C to 260°C | Applicable in high-temperature reactions |

| Size | Variety of sizes available (e.g., 10 mm, 20 mm) | Versatile for different container sizes |

| Cleaning | Easy to clean and reusable | Suitable for multiple experiments without contamination |

PTFE coated magnetic stir bars are essential tools in laboratories. They facilitate mixing of solutions without coming into direct contact with the reagents. This coating offers chemical resistance, making them suitable for a range of applications.

To maintain the integrity of your PTFE coated stir bars, proper care is crucial. Always rinse them with distilled water after use. Avoid harsh abrasives. Using a non-scratch cloth can help prevent wear on the PTFE surface. Store them in a dry place, away from direct sunlight, to prolong their lifespan.

**Tip:** Regular inspection for scratches or chips is wise. Small imperfections can affect stirring efficiency.

Cleaning often isn’t enough. Some chemical residues can adhere tightly. Use a gentle detergent if necessary. However, ensure to rinse thoroughly to avoid contamination in future experiments. Remember, maintenance goes beyond just cleaning; it involves ensuring the stir bars are functioning optimally.

**Tip:** Consider creating a log for usage and maintenance. This simple action can provide insights into your equipment's longevity. Over time, patterns can emerge to help improve care practices.