In the rapidly advancing field of material science, the application of PTFE coated magnetic materials has emerged as a significant innovation, offering enhanced performance and durability. According to a recent report published by the International Magnetic Materials Association, the demand for PTFE coated magnets has surged by over 30% in the last five years, driven primarily by their superior resistance to corrosion and heat. This makes them invaluable in a variety of industries, including automotive, aerospace, and medical devices.

Expert in the field, Dr. Emily Carter, a leading researcher on PTFE coated magnetic technologies, emphasizes the transformative impact of this innovation, stating, “The integration of PTFE coating in magnetic components not only extends their lifespan but also improves their operational efficiency in harsh environments.” This statement underlines the crucial role that PTFE coated magnetic materials play in enhancing product reliability and performance.

As industries increasingly seek solutions that can withstand extreme conditions, the adoption of PTFE coated magnetic applications continues to grow. This article will explore the reasons why PTFE coated magnets are becoming the preferred choice for engineers and manufacturers aiming for superior quality and longevity in their products.

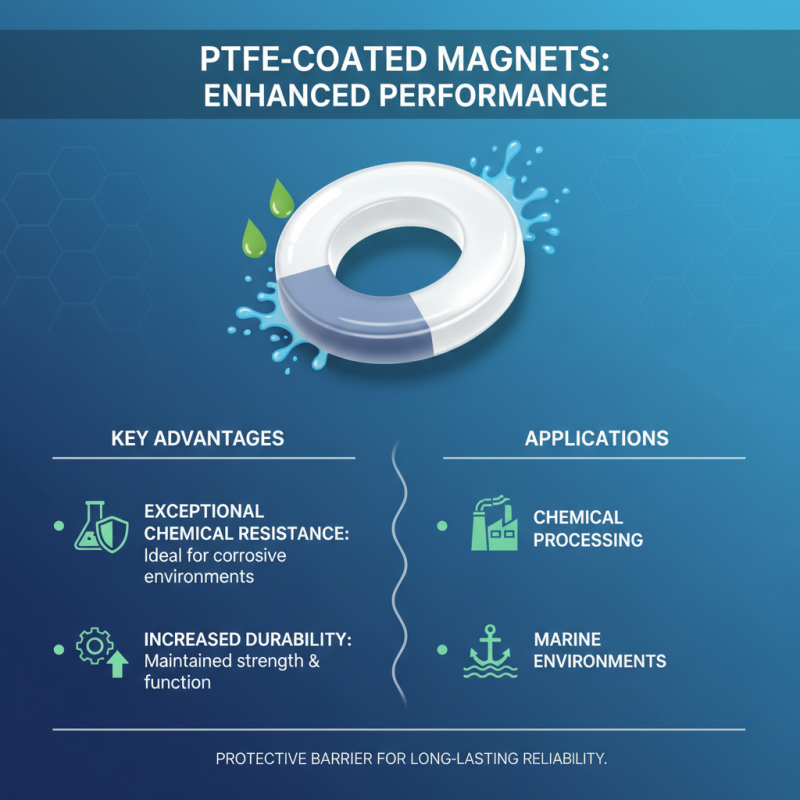

PTFE (Polytetrafluoroethylene) coated magnets offer several advantages that significantly enhance their performance and durability. One of the primary benefits of PTFE coating is its exceptional chemical resistance. This makes PTFE-coated magnets ideal for use in challenging environments, such as those encountered in chemical processing or marine applications, where exposure to corrosive substances can compromise the integrity of standard magnets. The coating acts as a protective barrier, ensuring that the magnet maintains its strength and functionality over time, regardless of the operating conditions.

Additionally, PTFE is well-known for its low-friction properties, which enhances the performance of magnets in applications requiring smooth operation. This is particularly beneficial in automated systems where magnetic components are involved in moving parts. The reduced friction minimizes wear and tear, leading to a longer lifespan of the magnet. Furthermore, PTFE-coated magnets are easier to clean, which is an important aspect in industries where hygiene is a priority. The non-stick characteristic of PTFE allows for quick and thorough cleaning, ensuring that the magnetic surfaces remain efficient and free from contamination. These benefits collectively contribute to the superior performance and reliability of PTFE-coated magnets in various industrial applications.

PTFE (Polytetrafluoroethylene) is a synthetic polymer that has gained recognition for its unique properties, particularly in enhancing the durability and longevity of magnets used in various applications. One of the most significant advantages of PTFE is its excellent resistance to high temperatures and corrosive environments. This intrinsic quality allows magnets coated with PTFE to maintain their magnetic strength and functionality over extended periods, even when exposed to harsh conditions that would typically degrade other materials.

In addition to thermal and chemical resistance, PTFE's low friction coefficient reduces wear and tear on magnets during operation. This characteristic minimizes the risk of physical degradation, further extending the lifespan of the magnetic components. By employing PTFE coatings, manufacturers can effectively improve the performance of magnets, ensuring they remain reliable and efficient in their applications. The enhanced durability provided by PTFE not only leads to reduced maintenance costs but also promotes sustainability by decreasing the frequency of replacements, thereby supporting more environmentally friendly practices within various industries.

| Property | PTFE Coated Magnets | Standard Magnets |

|---|---|---|

| Corrosion Resistance | Excellent | Poor |

| Operating Temperature Range | -200°C to 260°C | -50°C to 120°C |

| Surface Friction | Low | Moderate |

| Durability | High | Moderate |

| Chemical Resistance | Exceptional | Limited |

| Weight | Lightweight | Heavier |

| Longevity | Extended | Shorter |

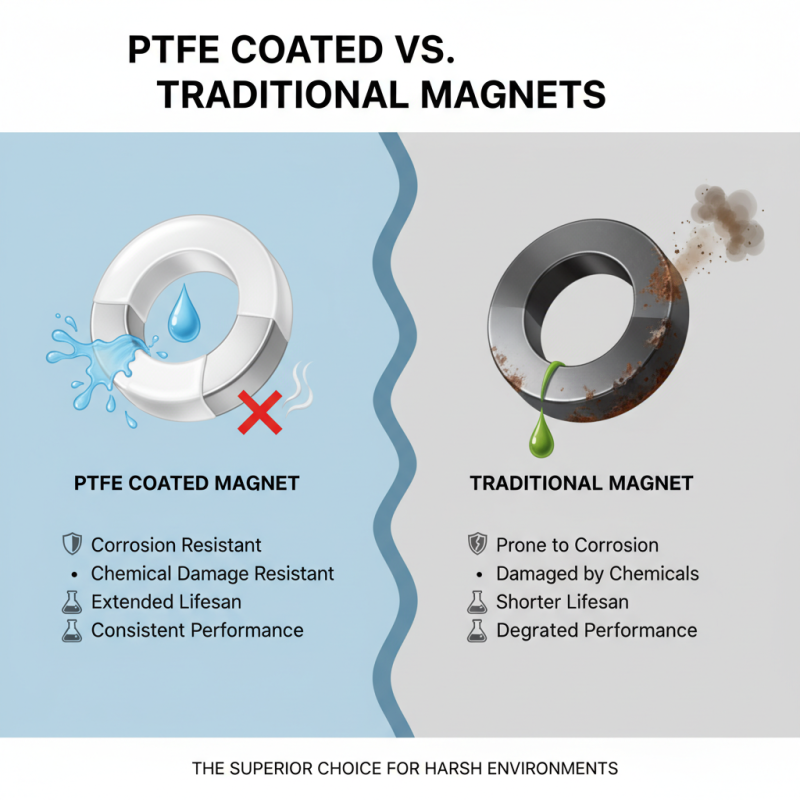

When comparing PTFE coated magnets to traditional magnets, several key differences highlight why PTFE coated options may be the superior choice for many applications. One prominent feature of PTFE coated magnets is their enhanced resistance to corrosion and chemical damage. Traditional magnets often suffer deterioration when exposed to harsh environments, such as moisture or caustic substances. In contrast, the PTFE coating creates a protective barrier that not only prolongs the life of the magnet but also maintains its performance under challenging conditions.

Another significant advantage of PTFE coated magnets is their non-stick properties. This characteristic reduces friction and allows for smoother operation in machinery where magnet interaction occurs. Traditional magnets can become stuck due to dust, debris, or contamination, leading to inefficient performance and increased maintenance needs. The smooth, non-adhesive surface of PTFE coated magnets minimizes these issues, resulting in more reliable functionality and less downtime in industrial settings.

Additionally, the versatility of PTFE coated magnets can be a game-changer for various applications, from automotive to medical devices. Their ability to withstand extreme temperatures and their ease of cleaning further differentiate them from traditional options, making them ideal for environments that demand strict hygiene and reliability. Ultimately, the performance benefits and durability of PTFE coated magnets position them as a preferred choice in many fields.

PTFE coated magnets have gained significant traction across various industries due to their unique properties that enhance performance and durability. In the food processing sector, for example, these magnets play a crucial role in ensuring product safety and quality. The non-stick surface of PTFE helps to prevent contamination, while its resistance to harsh cleaning chemicals ensures that the magnets remain effective and safe for use in environments where hygiene is paramount. Additionally, the high-temperature resistance of PTFE makes these magnets suitable for applications involving heat-intensive processes, further extending their usability.

In the industrial sector, PTFE coated magnets are utilized in conveyor systems to facilitate the movement of materials while maintaining magnetic strength. Their chemical resistance enables them to be employed in environments where exposure to solvents and corrosive substances is a concern. Furthermore, in the manufacturing of electronic devices, these magnets are favored for their ability to withstand external factors while delivering reliable performance, contributing to the longevity of the final product. Overall, the versatility of PTFE coated magnets allows for their application in diverse fields, revolutionizing operational efficiency and providing a robust solution to magnetic needs.

Proper maintenance of PTFE coated magnets is essential for ensuring their extended lifespan and optimal performance. One key practice is to regularly clean the magnets to remove any accumulated dust, dirt, or debris that can interfere with their functionality. A soft, damp cloth or a non-abrasive cleaning solution should be used to gently wipe the surface, maintaining the integrity of the PTFE coating. Avoiding harsh chemicals while cleaning is crucial, as they can damage the coating and compromise the magnet's effectiveness.

Another important aspect of maintenance is to store PTFE coated magnets in a cool, dry environment away from extreme temperatures and humidity. This helps prevent the degradation of the coating over time. Additionally, care should be taken to avoid mechanical shocks or impacts when handling these magnets, as such actions can chip or scratch the PTFE layer. By following these maintenance tips, users can maximize the durability and performance of PTFE coated magnets, ensuring they serve effectively in various applications.