The PTFE Magnetic Stir Bar is a critical tool in laboratories, providing efficient mixing for various applications. According to a report from the Global Laboratory Equipment Market, the demand for magnetic stirrers and accessories, including stir bars, has grown significantly, with an annual growth rate of 5.6%. This increase highlights the essential role of the PTFE Magnetic Stir Bar in scientific research and pharmaceutical development.

Dr. Emily Carter, a leading expert in laboratory equipment, stated, "The efficiency of a PTFE Magnetic Stir Bar can dramatically impact the outcomes of experiments." This statement underscores the importance of selecting the right stirring tools. The PTFE coating ensures chemical resistance and durability, making it suitable for diverse solutions.

However, users often overlook the necessity of maintaining these stir bars. Wear and tear can lead to ineffective mixing, causing experimental inconsistencies. It's vital for researchers to regularly evaluate their equipment. A well-maintained PTFE Magnetic Stir Bar can significantly enhance the productivity of laboratory work, yet many do not prioritize this aspect.

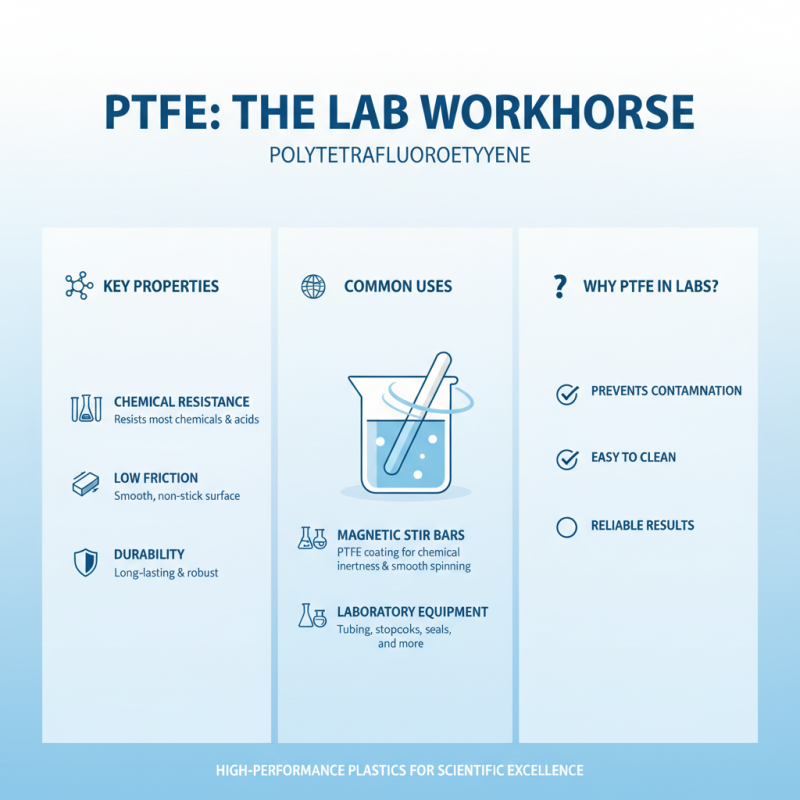

PTFE, or polytetrafluoroethylene, is a high-performance plastic known for its chemical resistance and low friction properties. It is commonly used in various laboratory applications. One notable use is in magnetic stir bars. These stir bars are coated with PTFE, which allows them to be chemically resistant and durable.

The role of PTFE in magnetic stir bars is significant. The coating provides a smooth surface that reduces friction during stirring. This ensures even mixing while preventing any unwanted reactions between the stir bar and the fluid. The non-stick nature of PTFE means that contaminants are less likely to adhere. However, not all PTFE is created equal. Some lower-quality PTFE coatings can wear off quickly, compromising the stir bar's effectiveness.

Magnetic stir bars function through a combination of magnetism and rotation. When placed in a magnetic stirrer, an internal magnet spins. This movement creates a vortex, effectively stirring the liquid. While this technology is reliable, the performance can vary based on factors like bar size and viscosity of the liquid. Understanding the limitations and benefits is key to optimizing their use in any laboratory setting.

PTFE magnetic stir bars are commonly used in laboratories for mixing solutions. Their structure is quite distinctive. Typically, they are made from polytetrafluoroethylene (PTFE), a highly resistant material. This material makes the stir bars not only chemically inert but also easy to clean. The design usually features a cylindrical shape, which allows for efficient stirring in various container sizes.

Inside these stir bars, a magnetic ferrite core is embedded. This core interacts with an external magnetic field generated by a stirrer. When the stirrer is activated, the core spins rapidly, causing the stir bar to whirl around. This motion creates turbulence in the liquid, promoting thorough mixing. However, sometimes, the spinning can be uneven. Factors like shape or placement can influence performance.

As with any tool, PTFE magnetic stir bars have limitations. The surface finish of the stir bar can wear over time. If the stir bar gets scratched, it may not perform as well, leading to poor mixing. Users should regularly inspect their stir bars for signs of wear. Monitoring is essential to ensure consistent mixing results.

Magnetic stirring is a widely used method in laboratories. It employs a magnetic stir bar, usually made of PTFE, which rotates in a liquid. The device consists of a stirring motor and a bar that contains magnets. When the motor spins, it creates a rotating magnetic field. This field causes the stir bar to spin as well, mixing the liquid evenly.

The principles behind magnetic stirring are simple yet effective. The liquids need to be placed in a flask with a stir bar inside. As the motor turns the magnets, the stir bar mimics this movement. This process improves mixing efficiency and can be used in various applications. Common usages include chemical reactions, biological experiments, and even cooking.

**Tips:** Ensure the stir bar is compatible with your liquid type. Some substances can cause wear on the bar. Monitor stirring speeds. Adjusting them can prevent splashing or uncontrolled mixing. If you notice uneven mixing, consider the size of your stir bar. It might be too small for the volume of liquid being stirred.

| Property | Description |

|---|---|

| Material | Polytetrafluoroethylene (PTFE) |

| Magnet Type | Permanent magnets embedded inside the stir bar |

| Function | To agitate liquids by magnetic field application |

| Working Principle | Magnetic stirring involves rotating the stir bar using a magnetic field generated by a stirrer |

| Applications | Used in laboratories for mixing solutions, culture media, and chemical reactions |

| Advantages | Non-contaminating, easy to clean, and efficient for homogenous mixing |

| Size Range | Available in various lengths typically from 1 inch to 5 inches |

PTFE magnetic stir bars are essential tools in laboratories. They are made from polytetrafluoroethylene, a non-reactive material. This allows them to handle various chemicals without contamination. Unlike traditional glass or metal stir bars, PTFE stir bars resist corrosion, making them ideal for harsh environments. Their smooth surface reduces friction, ensuring efficient mixing. Additionally, they operate silently. This makes them a preferred choice for sensitive experiments.

Using PTFE magnetic stir bars comes with notable benefits. Their durability and chemical resistance increase lab efficiency. The non-stick properties prevent sediment buildup, which can affect results. Researchers appreciate this feature for reliability. However, maintaining proper cleanliness is essential. Sometimes, residues may still adhere to the stir bar, complicating experiments. Inconsistent stirring can lead to varying outcomes, prompting researchers to monitor their mixing processes closely. Adaptability to high temperatures is another crucial aspect. PTFE stir bars can maintain their integrity, even under extremes. This versatility can lead to improved experimental protocols in diverse fields.

Proper maintenance of PTFE magnetic stir bars is essential for their longevity and performance. These stir bars often come into contact with various chemicals. It's crucial to clean them regularly to prevent contamination. After use, rinse the stir bars with distilled water. This simple step can remove most residues. For stubborn substances, mild soap can be used. However, avoid abrasive cleaners that might scratch the surface.

Storage is another aspect to consider. Keep the stir bars in a cool, dry place. Heat can warp them, while humidity may lead to corrosion in internal components. Inspect your stir bars periodically for any signs of wear or damage. Small cracks can go unnoticed but can affect stirring efficiency. If you notice any degradation, it's best to replace them. Neglecting these details might lead to less effective stirring and could waste valuable time in experiments. Just a little care goes a long way.