In the realm of laboratory equipment, the Ptfe Magnetic Stirrer stands out for its efficiency and versatility. Dr. Emily Chen, a renowned expert in chemical engineering, once mentioned, "The Ptfe Magnetic Stirrer revolutionizes mixing by offering seamless control and durability." This statement underscores the significance of using polytetrafluoroethylene (PTFE) in stirrer design.

The Ptfe Magnetic Stirrer is essential for precise mixing in various applications. Its robust PTFE coating provides chemical resistance and longevity. This gear not only helps in creating uniform solutions but also minimizes contamination risks. However, some users may overlook the importance of maintenance. Neglecting to clean the stirring bar can lead to inaccuracies.

Moreover, the initial setup might seem simple, yet it requires careful calibration. Too high or too low of a speed can affect the results. Users must be mindful of their specific mixing needs. The Ptfe Magnetic Stirrer, while effective, certainly has its learning curves. Understanding its capabilities will ensure optimal performance in any laboratory setting.

PTFE, or polytetrafluoroethylene, is a key material in magnetic stirrers. It is well-known for its non-stick properties and chemical resistance. This makes it ideal for laboratory settings where harsh chemicals are common. In a magnetic stirrer, PTFE is often used to coat the stirring bars. This helps in preventing contamination of samples during the stirring process.

When you use a magnetic stirrer, the PTFE-coated bar rotates in a liquid. The rotation creates a uniform mixture. This uniformity is crucial in many scientific experiments. According to industry reports, the efficiency of mixing can be improved by up to 25% when using a PTFE-coated stirring bar. This efficiency can save time and resources in lab work. However, improper use of these devices can lead to wear on the PTFE coating. Regular checks are necessary.

Tip: Ensure that the stirring speed is appropriate for the viscosity of the liquid. Too high a speed can cause excessive wear on the PTFE material.

PTFE also has good temperature stability. However, it can degrade under extreme conditions. Avoid exposing PTFE to temperatures above 260°C. Maintain the right environment for optimal performance.

Tip: Periodically inspect the condition of your PTFE stirring bars. Remove any scratches or contaminants promptly. This prolongs their lifespan and improves mixing effectiveness.

A PTFE magnetic stirrer is a powerful tool commonly used in laboratories. The key components of this device include a motor, a magnetic stir bar, and a PTFE-coated surface. The motor generates a rotating magnetic field. This field interacts with the stir bar, causing it to spin. The stirring action is efficient and produces a uniform mixture.

The PTFE coating on the stirrer adds an important layer. PTFE is known for its chemical resistance. This means it can handle various substances without corroding. Users must ensure the stir bar is compatible with the PTFE surface. Sometimes, mismatched materials can lead to issues in stirring effectiveness.

Regular cleaning of the stirrer is necessary, yet often overlooked. Residual samples can interfere with accuracy. Not everyone understands the need for regular inspection. Diligence here is key to maintaining optimal performance. An occasional check can save time and resources in the long run.

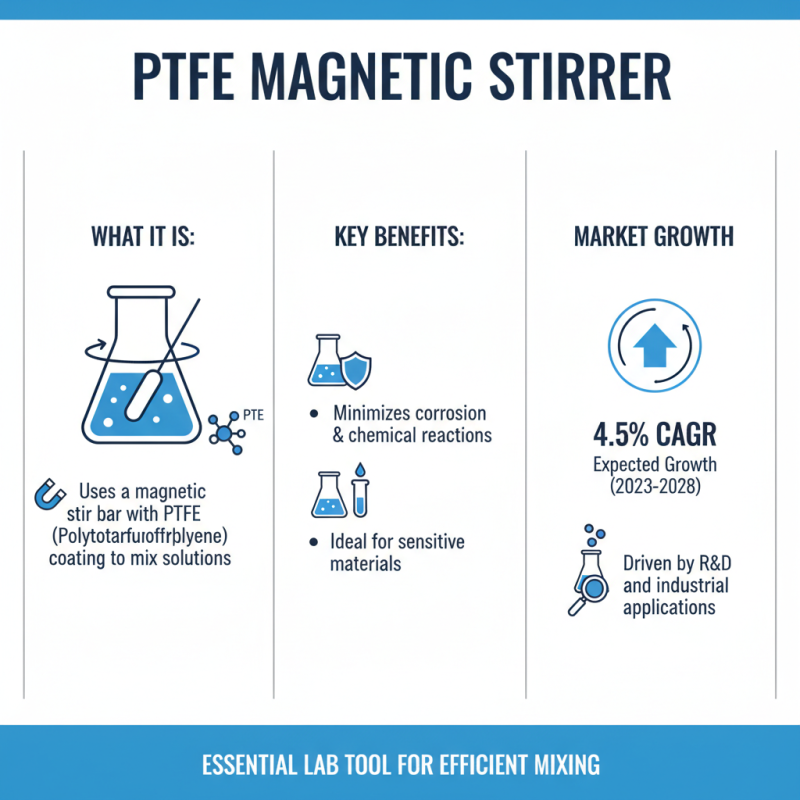

A PTFE magnetic stirrer is a valuable tool in laboratories and industrial settings. It uses a magnetic stir bar and a PTFE (polytetrafluoroethylene) coating to effectively mix solutions. The stirrer's design minimizes corrosion and chemical reactions, essential for sensitive materials. According to a recent market analysis, the magnetic stirrer market is expected to grow at a CAGR of 4.5% over the next five years, highlighting its importance in research and development.

To operate a PTFE magnetic stirrer, you begin by placing the desired liquid in a container. Ensure that the container is compatible with PTFE materials. Next, insert the magnetic stir bar into the liquid. The stir bar, coated in PTFE, is resistant to solvents. After positioning the container on the stir plate, turn on the unit. The magnet rotates beneath the plate, which causes the stir bar to spin and mix the liquid. The device’s speed can be adjusted, allowing for specific mixing requirements. However, achieving optimal stirring might require some trial and error, as the viscosity of the liquid can affect performance.

Keep an eye on the temperature and viscosity of your solutions while stirring. Some chemical reactions can generate heat, influencing the stirring process. It's worth noting that extreme speeds may lead to turbulence and inconsistent mixing. Lab technicians often find themselves reassessing their stirring strategies after observing undesired outcomes. Understanding the limits of a PTFE magnetic stirrer can lead to better results in your experiments.

PTFE magnetic stirrers are essential tools in laboratories. They utilize a magnetic field to stir solutions efficiently. These stirrers excel in applications where chemical resistance is vital. The PTFE coating protects the stirrer from harsh chemicals. It ensures minimal contamination of samples during experiments.

In biological and chemical research, PTFE magnetic stirrers find frequent use. They help in preparing solutions, mixing reagents, and maintaining homogeneity. Scientists appreciate their ability to handle acidic and alkaline substances without degradation. However, users should be cautious. Some solutions can still react with the stirrer’s components. Regular checks are advisable to ensure optimal performance.

Additionally, PTFE magnetic stirrers can save time. The consistent stirring quality improves experimental reproducibility. Yet, the initial setup may require some tweaking. Users often need to adjust speed settings based on the viscosity of the solution. Balancing speed and sample volume is crucial for effective mixing. This balance can sometimes be elusive. Ultimately, understanding these factors enhances laboratory outcomes.

PTFE coating is essential in magnetic stirring devices. It provides a unique advantage by enhancing resistance to chemicals and high temperatures. This shielding is crucial in laboratories where reactive substances are common. A magnetic stirrer with PTFE can facilitate smoother and more efficient mixing.

Using PTFE also simplifies maintenance. Spills and residues are easier to clean. This can be a significant benefit, especially in a busy lab environment. While effective, the cost of PTFE-coated devices can be higher. That factor sometimes leads to hesitations in purchasing decisions. Would the investment pay off in the long run?

Moreover, PTFE surfaces may not always maintain perfect integrity. Over time, scratches can occur. This may reduce the effectiveness of the coating. Users should regularly inspect their equipment. Small imperfections can compromise the performance of the stirrer. Balancing cost and quality remains a challenge for many users. The conversation around PTFE-coated magnetic stirrers continues to evolve.