In the realm of chemical processing, the integration of advanced materials plays a critical role in ensuring both safety and efficiency. Among these innovations, the PTFE mixing plug has emerged as a pivotal component, facilitating the seamless blending of various chemical formulations while mitigating hazards associated with corrosive substances. According to a recent industry report by MarketsandMarkets, the global market for PTFE products is projected to reach $1.17 billion by 2025, reflecting a compound annual growth rate (CAGR) of 4.6% from 2020. This growth is driven by the increasing demand for high-performance materials in laboratories and industrial settings where chemical integrity is paramount. By unlocking the secrets of PTFE mixing plugs, professionals can enhance operational efficiency, minimize contamination risks, and adhere to stringent safety standards that are vital for the protection of personnel and the environment.

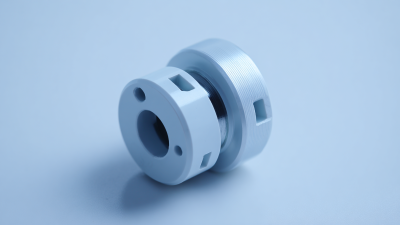

Polytetrafluoroethylene (PTFE) has become an essential material in chemical mixing processes, primarily due to its outstanding chemical resistance and thermal stability. This high-performance fluoropolymer exhibits remarkable inertness, enabling it to withstand aggressive chemicals without degrading. As a result, PTFE mixing plugs are increasingly favored in laboratories and industrial settings where hazardous substances are involved, ensuring both the integrity of the mixing apparatus and the safety of the operators.

In addition to its chemical durability, PTFE’s low-friction surface significantly enhances the efficiency of mixing operations. By minimizing friction between the mixing plugs and the materials being processed, PTFE facilitates smoother movement and uniform mixing, leading to improved operational performance. Moreover, the non-stick properties of PTFE reduce the likelihood of contamination and residue buildup, which are vital for maintaining purity in sensitive chemical applications. As industries continue to prioritize safety and efficiency, the role of PTFE in chemical mixing processes cannot be overstated, making it a crucial component in advancing modern chemical handling practices.

PTFE (polytetrafluoroethylene) mixing plugs play a crucial role in enhancing chemical safety across various industries. The unique chemical resistance properties of PTFE make it ideal for handling aggressive solvents and acids, effectively preventing contamination and unwanted reactions. According to a report by the International Chemical Safety and Security Network, utilizing high-quality PTFE mixing plugs can reduce the risk of chemical spills by up to 50%, demonstrating significant potential for safety improvements.

In addition to safety, PTFE mixing plugs also contribute to operational efficiency. Their design minimizes mixing time while maintaining homogeneity in chemical processes, thus increasing productivity. A study from the Journal of Chemical Engineering indicates that the use of PTFE plugs can enhance mixing efficiency by 30%, allowing for cost savings in both time and materials.

Tips: When selecting PTFE mixing plugs, always consider the chemical compatibility with specific substances being used. Ensure that the plugs are properly installed to prevent leaks, and regularly inspect them for wear and tear. This proactive approach will help maintain optimal safety and efficiency in your chemical operations.

PTFE mixing plugs are essential tools in various chemical processes, enhancing both efficiency and safety. Made from polytetrafluoroethylene, these plugs offer exceptional chemical resistance, allowing them to withstand harsh environments without degrading. By providing a secure seal, PTFE mixing plugs minimize the risk of spills and chemical exposure, making laboratories and production facilities safer for workers.

To maximize the efficiency of PTFE mixing plugs, it’s crucial to ensure proper installation. Tips for effective usage include regularly checking the integrity of the seals, as worn or damaged plugs can compromise safety. Additionally, consider using plugs that fit your equipment perfectly, as a good fit prevents leaks and ensures optimal mixing. Compatibility between PTFE and the chemicals being used is also key—always verify that the materials are suitable for the specific applications to maintain safety and efficiency.

Incorporating PTFE mixing plugs into your chemical processes not only improves operational efficiency but also fosters a safer working environment. Regular maintenance checks and choosing the right plug for your specific needs will significantly enhance the effectiveness of your chemical handling operations. Always remember to stay informed about the best practices for using these invaluable tools.

| Dimension | Description | Benefits | Applications |

|---|---|---|---|

| Material Composition | Polytetrafluoroethylene (PTFE) | Chemical resistance, low friction | Chemical processing, pharmaceuticals |

| Temperature Range | -200°C to 260°C | Versatile in extreme conditions | Research labs, industrial processes |

| Mixing Efficiency | Uniform distribution of materials | Improves reaction rates, consistency | Paints, coatings, food processing |

| Safety Features | Non-reactive and non-toxic | Reduces risk of contamination | Laboratories, food production |

| Durability | Resistance to wear and tear | Longer operational lifespan | Manufacturing, recycling |

PTFE mixing plugs are a crucial component in various chemical processes, particularly due to their outstanding chemical resistance and low friction properties. One key feature of high-quality PTFE mixing plugs is their ability to withstand a wide range of temperatures, typically ranging from -200°C to 260°C. According to a report by the American Chemical Society, materials like PTFE exhibit exceptional stability under extreme thermal conditions, making them ideal for industries dealing with aggressive substances.

Another vital aspect is the design and precision of the mixing plugs. High-quality PTFE plugs often incorporate a great fit with minimal leakage, enhancing both safety and efficiency during chemical reactions. A study published in the Journal of Chemical Engineering highlights that well-designed PTFE plugs reduce the risk of contamination and chemical exposure, which can lead to safer working environments and improved operational efficiency.

Tips: When choosing PTFE mixing plugs, always verify their compatibility with the chemicals used in your process. Additionally, consider the torque specifications provided by manufacturers to ensure a secure fit that minimizes leakage. Regularly inspect these components for wear and damage to maintain optimal performance and safety in your operations.

In the complex world of industrial processes, ensuring chemical safety and efficiency is paramount. Implementing PTFE (Polytetrafluoroethylene) mixing solutions can significantly enhance these aspects by providing superior chemical resistance and longevity. When industries adopt PTFE mixing plugs, they not only achieve safer handling of aggressive chemicals but also streamline their operations by reducing maintenance needs.

Tips for Implementing PTFE Mixing Solutions:

Moreover, companies should proactively assess their mixing processes. Integration of advanced technologies can assist in optimizing the use of PTFE. For instance, leveraging innovative monitoring tools can provide valuable data on mixing efficiency, allowing for adjustments that enhance both productivity and safety in chemical environments.