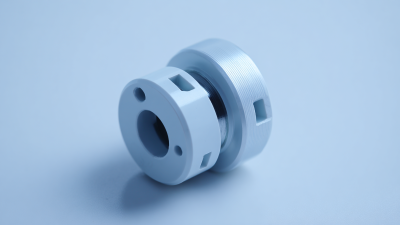

In the realm of laboratory performance, the importance of effective mixing and agitation cannot be overstated. According to a recent report by Research and Markets, the global laboratory stirrers market is projected to reach $1.2 billion by 2026, driven by advancements in laboratory processes and the growing demand for precise outcomes. A pivotal component of this process is the PTFE stirrer bar, renowned for its exceptional chemical resistance and uniform mixing capabilities. These stirrer bars not only enhance mixing efficiency but also minimize contamination risks due to their non-reactive nature. As laboratories continuously strive for optimal performance and reproducibility in experiments, incorporating high-quality PTFE stirrer bars becomes essential for achieving desired results and maintaining effectiveness in various applications.

The durability of PTFE stirrer bars is a critical factor when it comes to selecting equipment for laboratory environments. PTFE, or polytetrafluoroethylene, is renowned for its high chemical resistance and thermal stability. According to a report by Research and Markets, the chemical resistance properties of PTFE allow it to withstand a wide range of acids, bases, and solvents without degradation, making it an invaluable asset for laboratories handling corrosive substances. This durability translates into long-term cost savings, as PTFE stirrer bars require less frequent replacement compared to their metal counterparts, which can suffer from wear and corrosion.

Furthermore, the thermal stability of PTFE ensures that stirrer bars maintain optimal performance even in high-temperature applications. The material can typically withstand temperatures up to 260°C (500°F) without losing its structural integrity. In a study published in the Journal of Materials Science, it was found that PTFE stirrer bars exhibited minimal wear even after extensive use in rigorous stirring processes. This longevity not only enhances efficiency but also reduces the need for periodic downtime due to equipment failure. As laboratories continue to prioritize operational efficiency and sustainability, investing in PTFE stirrer bars emerges as a smart choice for maintaining optimal laboratory performance over time.

PTFE stirrer bars play a crucial role in ensuring safety and reliability in laboratory experiments, primarily due to their enhanced chemical resistance. Polytetrafluoroethylene (PTFE) is known for its exceptional ability to withstand harsh chemical environments, which is vital in conducting experiments involving corrosive reagents. According to a report by the American Chemical Society, PTFE materials demonstrate superior resistance to over 3,000 industrial chemicals, making them invaluable assets in various laboratory applications. This robustness not only prolongs the lifespan of the stirrer bars but also minimizes the risk of contamination and chemical reactions that could lead to hazardous situations for laboratory personnel.

Moreover, the widespread adoption of PTFE stirrer bars across various scientific disciplines underscores their importance in maintaining optimal laboratory performance. A study published in the Journal of Laboratory Automation highlighted that laboratories utilizing PTFE components reported a 40% reduction in maintenance costs and fewer equipment failures compared to those using traditional materials. This data emphasizes that investing in PTFE stirrer bars not only enhances safety during experimental procedures but also contributes to overall operational efficiency by optimizing time and resources in the laboratory setting.

In laboratory processes, achieving optimal mixing efficiency is paramount, and PTFE stirrer bars play a crucial role in this function. Their unique chemical resistance and non-stick properties allow them to operate effectively with a variety of substances without contaminating the samples. This characteristic not only enhances the quality of the results but also extends the lifespan of the stirrer bars, as they are less susceptible to wear and corrosion than their metal counterparts.

When using PTFE stirrer bars, it’s essential to ensure that the size and shape match the vessel's dimensions for effective mixing. Selecting the right stirrer can significantly reduce mixing times and improve homogeneity in solutions. Additionally, consider using larger stirrer bars for more viscous solutions, as they provide better torque and mixing capability.

For optimal performance, keep your PTFE stirrer bars clean by washing them with appropriate solvents after each use, especially when transitioning between different chemicals. This practice not only helps maintain their effectiveness but also prevents cross-contamination, ensuring the integrity of your laboratory results. Remember that investing in high-quality PTFE stirrer bars is crucial for laboratories aiming for precision and efficiency in their mixing processes.

| Reason | Description | Impact on Lab Processes |

|---|---|---|

| Enhanced Chemical Resistance | PTFE stirrer bars withstand a wide range of corrosive chemicals. | Increases durability and reduces equipment replacement costs. |

| Temperature Stability | Effective under extreme temperature conditions. | Supports a broader range of experiments without loss of performance. |

| Low Surface Energy | Reduces adhesion of substances, ensuring a smooth mixing action. | Minimizes contamination and improves experimental accuracy. |

| Magnetic Properties | Compatibility with magnetic stirrers for efficient mixing. | Provides reliable and consistent stirring motion. |

| Versatility in Applications | Suitable for various types of liquids and mixtures. | Enhances laboratory flexibility for different experimental setups. |

| Ease of Cleaning | PTFE materials make cleaning effortless due to their non-stick properties. | Saves time and ensures compliance with cleanliness standards. |

| Consistent Mixing Performance | Offers stable and uniform stirring across all types of samples. | Enhances data reliability and reproducibility in experiments. |

In laboratory environments, cleanliness and ease of maintenance are paramount. PTFE stirrer bars are designed to meet these demands, offering significant advantages over traditional materials. One of the standout features of PTFE (polytetrafluoroethylene) is its non-stick properties, which minimize the adherence of samples and prevent contamination. This characteristic not only ensures that experiments remain uncontaminated but also allows for a quicker and more efficient cleanup process after experiments. Lab technicians can easily rinse or wipe down PTFE stirrer bars without the need for harsh chemicals, which aids in preserving the integrity of their equipment.

Moreover, the chemical resistance of PTFE makes it suitable for a wide range of laboratory applications. Whether working with acids, bases, or organic solvents, PTFE remains inert and functional, reducing the risk of material degradation that could complicate maintenance. This resilience contributes to the longevity of the stirrer bars, allowing laboratories to maintain a clean and efficient workspace with minimal downtime. With such advantages, it’s evident that PTFE stirrer bars not only support optimal performance in laboratories but also simplify the overall maintenance and operational procedures.

This bar chart illustrates the importance of various properties of PTFE stirrer bars, highlighting their role in enhancing laboratory performance. Each property is rated on a scale from 1 to 10, showcasing how vital they are for effective laboratory operations.

When it comes to laboratory equipment, the cost-effectiveness of

PTFE (Polytetrafluoroethylene) stirrer bars

is a significant factor that laboratories cannot afford to overlook.

PTFE stirrer bars are not only durable and resistant to chemical corrosion,

but they also provide a reliable solution for efficient mixing processes.

According to a report from the National Institute of Standards and Technology,

labs can save up to

30%

on maintenance costs by integrating high-quality stirrer bars, as their longevity

reduces the frequency of replacements.

Implementing PTFE stirrer bars can lead to notable savings in both time and money.

Their efficiency in promoting uniform mixing can decrease the duration of experiments,

thus allowing laboratories to maximize productivity. Additionally, a study by the

Journal of Laboratory Automation highlighted that investing in quality laboratory consumables,

such as PTFE stirrer bars, can elevate the overall laboratory performance by

25%, aligning with budgetary constraints

while enhancing output quality.

Tips: To further maximize the effectiveness

of your laboratory budget, consider purchasing PTFE stirrer bars in bulk, which often

results in significant discounts. Regular maintenance of laboratory equipment, including

stirrer bars, will extend their lifecycle, ensuring that your investments yield optimal returns.