In laboratory settings, achieving optimal mixing results is crucial. PTFE stirrers are widely recognized for their efficiency and versatility. These tools play a significant role in various applications, from chemical reactions to blending solutions.

Using the right PTFE stirrer can significantly impact the outcome of experiments. Precision mixing requires careful consideration of stirrer design and material. PTFE stands out due to its excellent chemical resistance. However, choosing a stirrer isn't always straightforward.

Some users may overlook specific requirements, leading to subpar mixing. Ignoring aspects such as stirrer size, rotation speed, and container shape can affect results. It's essential to evaluate how the PTFE stirrer interacts with the medium and the process involved. A well-chosen stirrer can enhance efficiency, while a poor choice can hinder progress. Experimentation and reflection on mixing practices are vital for better outcomes.

When it comes to optimal mixing, PTFE stirrer tips play a vital role. Their non-stick surface prevents material build-up, making cleaning easier. These tips are resistant to many chemicals, which increases their usability in various environments. Additionally, their durability ensures long-term performance, reducing the need for frequent replacements.

An essential feature of PTFE stirrer tips is their versatility. They come in different shapes and sizes, allowing for precise mixing of various substances. For instance, wider tips facilitate mixing thicker liquids effectively. Smaller tips can reach into narrower containers, ensuring no residue is left behind. This adaptability also extends to temperature tolerance, which means they can handle both hot and cold mixtures without degradation.

However, mixing results can vary based on technique and application. Users often overlook how the angle of insertion affects effectiveness. A steep angle might lead to inadequate mixing in some cases. Experimenting with different approaches is necessary to achieve the best results. Not every mix will yield perfect outcomes on the first try. Adjustments and reflections on past attempts help refine the process.

| Tip Type | Length (mm) | Diameter (mm) | Maximum Temperature (°C) | Chemical Resistance |

|---|---|---|---|---|

| Straight Tip | 100 | 10 | 260 | High |

| Angle Tip | 150 | 12 | 260 | Very High |

| Flexible Tip | 200 | 8 | 260 | Moderate |

| Low-Viscosity Tip | 120 | 9 | 260 | High |

| High-Viscosity Tip | 180 | 15 | 260 | Very High |

PTFE stirrer tips are essential for optimal mixing in various applications. They offer durability and chemical resistance that regular stirrers can't match. Depending on the application, different types of PTFE stirrer tips serve specific purposes. For example, a flat tip is suitable for mixing viscous liquids, while a pointed tip penetrates surfaces easily.

In some cases, the wrong type of stirrer tip can hinder performance. A common mistake is using a flat tip for thin liquids. This can lead to inefficient mixing and inconsistent results. It's important to choose the right shape based on the fluid's viscosity.

Considerations also extend to the size of the stirrer tip. A larger tip can cover more area but may create excess turbulence. Balance is key. Always evaluate the specific needs of your mixing task. Minor adjustments can lead to significant improvements. Choose wisely for the best outcome in your mixing endeavors.

Selecting the right PTFE stirrer tip is crucial for achieving optimal mixing results. PTFE is known for its excellent chemical resistance, which makes it ideal for various applications. However, not all stirrer tips are created equal. Their design can significantly influence the efficiency of your mixing process. According to industry reports, using the wrong stirrer tip can lead to inconsistencies in product quality and prolonged mixing times.

When choosing a PTFE stirrer tip, consider the viscosity of your mixture. For thicker substances, a wider tip may be necessary to facilitate better flow. Conversely, a narrower tip works well with low-viscosity liquids. It’s essential to match the stirrer tip to the specific characteristics of the materials being mixed. This attention to detail can reduce waste and improve outcomes.

Tip 1: Always evaluate the temperature and pressure conditions of your processes. Extreme conditions can impact the performance of your PTFE tip.

Tip 2: Regularly inspect the stirrer tips for signs of wear or damage. A worn tip can compromise your mixing efficiency and product integrity.

Selecting an appropriate PTFE stirrer tip is not just about the size. It involves understanding the specific needs of your process. This careful approach can help mitigate risks and improve overall mixing performance.

Maintaining PTFE stirrer tips is crucial for optimal performance. Regular cleaning is essential. Residue buildup can lead to ineffective mixing and potential contamination. Reports indicate that a clean stirrer can enhance mixing efficiency by up to 30%. This is significant in industries where precision is key.

Care for PTFE tips includes avoiding harsh chemicals. Use soft cloths and gentle solutions for cleaning. Implementing a weekly maintenance schedule can drag down wear and prolong lifespan. Some users neglect this step, leading to frequent replacements. Data shows that proper maintenance can extend the life of PTFE stirrers by 50% or more, depending on usage conditions.

Installation and storage matter too. Improper handling can cause micro-cracks or deformities. It is vital to store stirrers in a designated area, away from potential damage. Regular inspections help identify wear early on. Keeping a log of usage helps monitor when maintenance is due. Small cracks, if ignored, can result in bigger issues down the line.

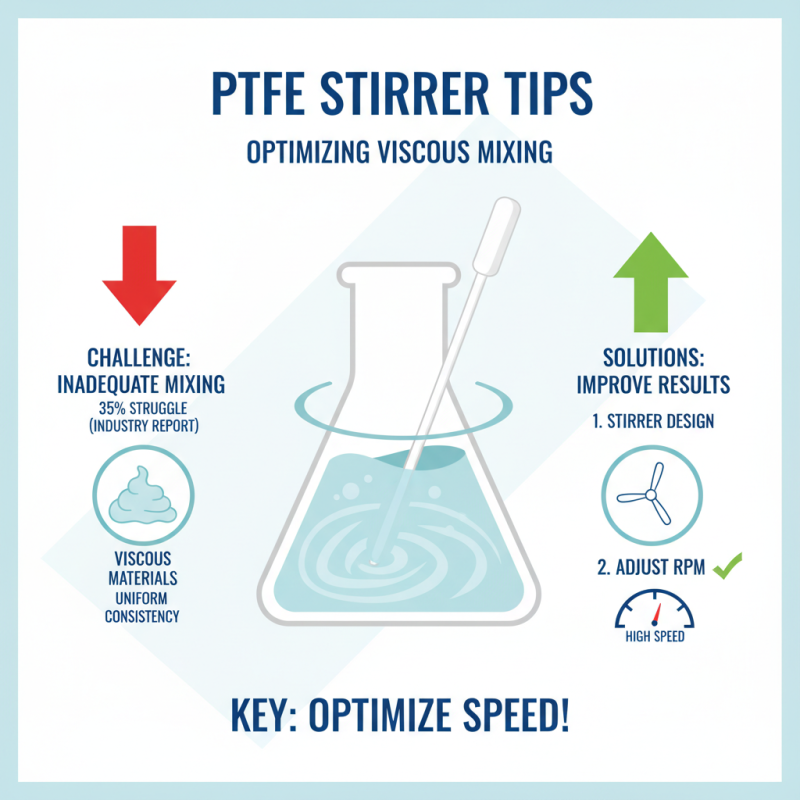

Mixing with PTFE stirrer tips often leads to excellent results, but challenges can arise. One common issue is inadequate mixing of viscous materials. According to industry reports, 35% of users struggle with achieving uniform consistency in thick substances. This often stems from the stirrer's design or insufficient speed settings. Adjusting the stirrer's RPM can significantly improve results, yet many neglect this simple step.

Another prevalent problem is contamination. PTFE is known for its chemical resistance, yet impurities can still affect the final product. A study found that 25% of mixing failures are due to improper cleaning of equipment. Effective cleaning protocols are paramount. Users should consider dedicated cleaning cycles between different batches to prevent cross-contamination. Neglecting these practices can lead to inconsistent quality.

Temperature control during mixing also plays a crucial role. A significant percentage of users reported issues with heat-sensitive materials. As temperatures rise, viscosity may decrease, leading to unexpected behaviors. Analyzing temperature ranges can provide insights into optimal mixing conditions. Ignoring this can result in subpar outcomes or even complete batch failure. Vigilance in these aspects ensures the best possible mixing results with PTFE stirrer tips.