In the world of precision tasks, selecting the right tools is essential for achieving high-quality results. One tool that stands out for its exceptional properties is PTFE tweezers. Made from polytetrafluoroethylene, these tweezers offer unique advantages that make them ideal for various applications, from electronics assembly to laboratory work. Their non-stick surface and excellent chemical resistance ensure that they can handle delicate components without causing damage or contamination, making them an invaluable tool for professionals in numerous fields.

The versatility of PTFE tweezers goes beyond their physical characteristics. They are lightweight and ergonomic, allowing for comfortable and precise handling, which is crucial when working on intricate tasks where every movement counts. Furthermore, their ability to withstand high temperatures without degrading enhances their usability in scenarios that involve heat, making them a preferred choice for those who require assurance in their tools' capabilities.

Using PTFE tweezers can significantly improve both the efficiency and effectiveness of precision tasks. Whether you're assembling electronic devices, conducting scientific experiments, or working with sensitive materials, incorporating these tweezers into your toolkit is a smart move. With their reliable performance, PTFE tweezers not only simplify the process but also elevate the standard of work, ensuring that every detail is attended to with care.

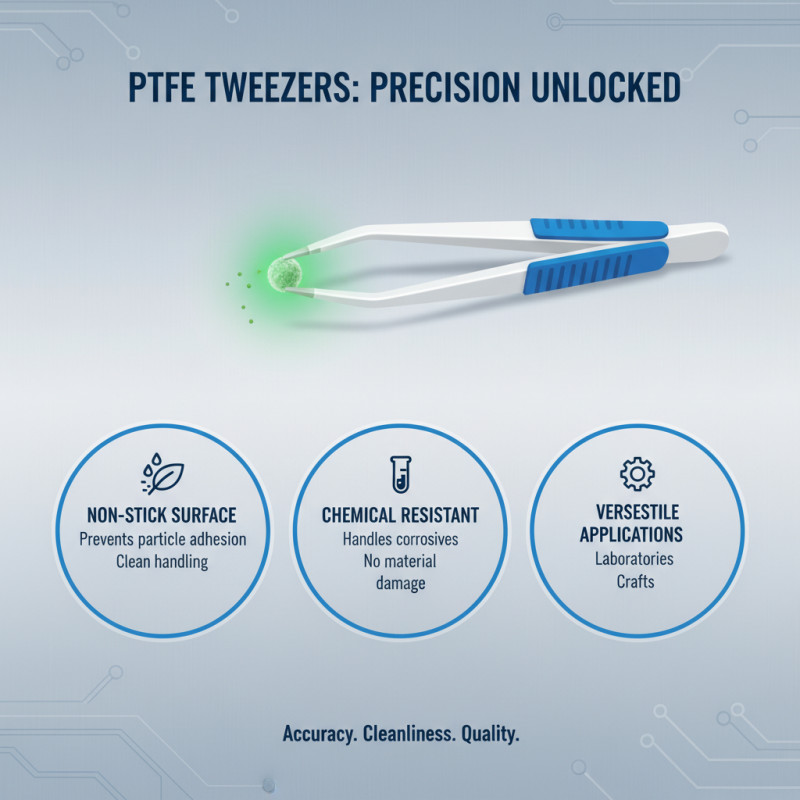

PTFE, or polytetrafluoroethylene, is a highly versatile synthetic polymer renowned for its remarkable properties that make it ideal for precision tasks in various industries. One of the most significant characteristics of PTFE is its exceptional non-stick surface, which allows for easy release of materials without adhesion. This property is particularly advantageous in delicate operations, such as electronics assembly or laboratory work, where the risk of contamination or damage to small components is high.

Moreover, PTFE exhibits outstanding chemical resistance, which is crucial in applications where exposure to aggressive substances may occur. According to a report by the American Society for Testing and Materials, PTFE retains its integrity and functionality even when exposed to a wide range of acids, bases, and solvents. This durability ensures that PTFE tweezers can be safely used in diverse environments, from manufacturing to research laboratories. Additionally, PTFE's high-temperature resistance enables its use in scenarios involving heat-sensitive materials, further enhancing its reputation as an essential tool for precision tasks.

In light of these unique properties, PTFE tweezers become indispensable for professionals seeking accuracy and efficiency. Their non-conductive nature also makes them suitable for handling electronic components, minimizing the risk of static discharge. With their unique combination of features, PTFE tweezers represent a significant advancement in precision tool manufacturing, meeting the growing demands of various technical fields.

PTFE tweezers, made from polytetrafluoroethylene, are essential tools in fields where precision is paramount. Their non-stick properties and chemical resistance make them ideal for working with delicate components, especially in the electronics industry. When handling sensitive parts like circuit boards or microchips, the risk of electrostatic discharge (ESD) and contamination is significant. PTFE tweezers mitigate these risks effectively, allowing technicians to grasp and manipulate components without affecting their integrity.

In the realm of laboratory applications, PTFE tweezers excel in tasks such as sample handling and manipulation of reactive materials. Their ability to withstand harsh chemicals ensures that they remain functional even in corrosive environments, making them invaluable in chemical and biological laboratories. Additionally, these tweezers are used in jewelry making, where precision is essential for assembling intricate designs without damaging fragile materials. The non-adhesive nature of PTFE ensures that even the tiniest parts can be handled with care and without the concern of residue being left behind.

PTFE (Polytetrafluoroethylene) tweezers have become increasingly popular in various precision tasks due to their unique properties that set them apart from traditional materials. One significant advantage of PTFE tweezers is their non-stick surface, which prevents fine particles, adhesives, and chemicals from adhering to the tweezers. This feature is particularly beneficial in electronics, laboratory settings, and crafts, where maintaining cleanliness is crucial for accuracy and quality. Additionally, PTFE is chemically resistant, making these tweezers suitable for handling substances that could corrode or damage other materials.

Another notable benefit of PTFE tweezers is their excellent thermal resistance. Unlike metal tweezers, PTFE tweezers won't conduct heat, allowing you to work safely with hot components without the risk of burns. This makes them ideal for soldering or working with heated materials in various applications. Moreover, their lightweight design enhances maneuverability, enabling you to perform intricate tasks with ease.

Tip: When using PTFE tweezers, always ensure your workspace is organized to avoid loss of small components. Additionally, regularly clean your tweezers with appropriate solvents to maintain their effectiveness. Lastly, when handling sensitive electronic components, practice a gentle grip to prevent damage while still providing sufficient support.

Proper use and maintenance of PTFE tweezers are essential for achieving optimal performance during precision tasks. When utilizing PTFE tweezers, it is crucial to handle them with care to avoid any accidental damage. Always grip the tweezers by the insulated handles, avoiding excessive pressure on the tips to preserve their integrity. For tasks that require delicate handling, such as electronics assembly or jewelry making, ensure that the tweezers are clean and free from contaminants to prevent any transfer of dirt or oils onto the items being manipulated.

Regular maintenance of PTFE tweezers involves cleaning and inspecting them after each use. To clean, use a soft cloth or a gentle cleaning solution that won't damage the PTFE surface. Avoid abrasive materials that can scratch or degrade the tips. Additionally, check for any signs of wear or deformation periodically. If you find any irregularities, it may be time to replace the tweezers to maintain precision and functionality. By following these guidelines, you can ensure that your PTFE tweezers remain in optimal condition, ready to assist in various precision tasks with effectiveness and reliability.

PTFE tweezers, made from polytetrafluoroethylene, are essential tools in various industries where precision and non-reactivity are paramount. One of the primary sectors utilizing PTFE tweezers is the electronics industry. In this field, professionals often handle sensitive components that can easily be damaged by static electricity or contamination. The non-stick surface of PTFE reduces the risk of residue transfer and static buildup, making these tweezers ideal for assembling and repairing electronic devices.

Another significant industry that benefits from PTFE tweezers is the laboratory sector, where precision in handling samples and reagents is crucial. Researchers and technicians often use PTFE tweezers to manipulate delicate materials without introducing contaminants that could compromise experiments.

In addition to laboratories, PTFE tweezers are also valuable in the medical field, especially in surgical settings where the need for sterile, non-reactive tools is critical. Their thermal resistance allows for usage in high-temperature conditions, ensuring that they perform reliably in intricate procedures.