As laboratories continue to evolve with advancements in technology and materials, the significance of choosing the right equipment cannot be overstated. In 2025, one of the most compelling options for mixing and stirring solutions is the PTFE stir bar. These innovative tools are gaining recognition due to their exceptional chemical resistance and versatility, making them ideal for a variety of applications in research and industrial settings.

The unique properties of PTFE stir bars allow them to withstand harsh chemicals and extreme temperatures, ensuring reliable performance across numerous experiments. Their non-stick surface not only facilitates efficient stirring but also minimizes contamination risk, thus enhancing the accuracy of scientific results. Whether you're conducting complex chemical reactions or basic mixing tasks, the decision to integrate PTFE stir bars into your laboratory toolkit can lead to improved efficiency and safety.

In the dynamic landscape of laboratory equipment, opting for PTFE stir bars represents a strategic choice for researchers seeking durability, reliability, and high performance. As we advance further into 2025, understanding the benefits of these unparalleled stir bars will be crucial for any laboratory striving to maintain cutting-edge practices and achieve exemplary results.

In the evolving landscape of laboratory equipment, PTFE (Polytetrafluoroethylene) stir bars emerge as an essential component for enhancing laboratory efficiency. PTFE is renowned for its unique properties, including excellent chemical resistance, high thermal stability, and a low coefficient of friction, making it ideal for a variety of applications. According to a report by the American Chemical Society, labs utilizing PTFE materials report a 30% increase in the longevity of stirring equipment due to their inert nature, which prevents reactions with a wide range of chemicals.

Moreover, PTFE stir bars possess the ability to operate effectively across a broad temperature range, from -200°C to +260°C. This adaptability is particularly crucial for laboratories engaged in diverse experimental conditions, as highlighted by data from the Journal of Laboratory Automation, which states that efficient temperature management can lead to a 25% reduction in preparation time for experiments. The low friction characteristics of PTFE also minimize wear and tear on stirring apparatus, which translates to lower maintenance costs and reduced downtime—key indicators of operating efficiency in laboratory settings.

Furthermore, the non-stick surface of PTFE stir bars aids in maintaining sample purity, as it prevents residue buildup. This attribute is critical in fields such as pharmaceuticals and biochemistry, where contamination can skew results or lead to failed experiments. Research conducted by various industry experts suggests that using PTFE stir bars can enhance reproducibility in experimental outcomes, promoting greater reliability in data collection—a fundamental requirement for scientific advancements. As laboratories aim to improve their operational efficacy in 2025 and beyond, the integration of PTFE stir bars should be a priority for researchers seeking to streamline their processes.

| Property | Description | Benefits |

|---|---|---|

| Chemical Resistance | Resistant to a wide variety of corrosive substances | Enhances longevity and reliability in harsh environments |

| Temperature Stability | Effective in a wide temperature range from -200°C to 260°C | Enables diverse applications without risk of degradation |

| Non-Stick Surface | Low surface energy prevents material accumulation | Facilitates easy cleaning and minimizes contamination |

| Magnetic Properties | Compatible with magnetic stirring | Improves mixing efficiency and reduces energy consumption |

| Durability | Withstands wear and tear from continuous use | Cost-effective option due to fewer replacements needed |

PTFE stir bars, or polytetrafluoroethylene stir bars, have gained significant traction in laboratory settings, particularly as researchers seek more reliable and efficient options for their mixing needs. One of the primary advantages of PTFE stir bars is their exceptional chemical resistance. Unlike traditional stir bars, which can corrode or react with various solvents, PTFE stir bars remain inert, ensuring that samples are not contaminated during mixing. This feature is crucial for experiments requiring high purity and precision, marking a considerable step forward in laboratory practices.

Moreover, PTFE stir bars provide superior temperature tolerance, allowing them to be used in a wide range of experimental conditions without compromising performance. Their ability to withstand extreme temperatures enables them to function effectively in heated reactions as well as in low-temperature environments. Additionally, the smooth, non-stick surface of PTFE stir bars minimizes the risk of sample adhesion, promoting efficient mixing and reducing the time spent on cleaning and maintenance. As laboratories continue to evolve, the shift towards PTFE stir bars is becoming increasingly clear, as they offer a combination of durability, reliability, and versatility that traditional options simply cannot match.

PTFE stir bars have become essential tools in laboratories across various fields due to their unique properties and versatility. Commonly used in chemical and biological research, these stir bars offer excellent chemical resistance, enabling them to blend solutions without contamination from the stirring device itself. Their non-stick nature ensures that samples remain untainted, making them ideal for sensitive applications such as pharmaceutical research and high-precision assays.

In addition to traditional uses in chemistry, PTFE stir bars are increasingly found in environmental science laboratories, where they can assist in the mixing of volatile compounds without risking degradation of the sample. They are particularly effective in applications involving corrosive substances, where other materials would fail. The use of PTFE stir bars enhances laboratory safety by minimizing the risk of reaction with the stir bar material, ensuring a more reliable experimental process.

Tips: When selecting PTFE stir bars for your lab, consider their size and shape based on the volume of liquid you'll be mixing. Opt for bars with a smooth finish to enhance durability and prevent wear over time. Regularly inspect your stir bars for signs of wear or damage to maintain accuracy in your experiments.

In the modern laboratory setting, cost-effectiveness and longevity are vital factors influencing equipment choices. PTFE (Polytetrafluoroethylene) stir bars are increasingly recognized for their affordability and durability, making them a preferred choice in 2025. According to recent industry reports, PTFE stir bars can have a lifespan up to five times longer than traditional materials, significantly reducing the frequency and costs of replacements. With an average laboratory spending approximately 15% of its budget on consumables, opting for PTFE stir bars allows facilities to maximize their resources while maintaining operational efficiency.

Moreover, the chemical resistance and non-stick properties of PTFE significantly enhance the performance of stir bars, leading to fewer instances of contamination and more accurate results. Studies show that labs that switched to PTFE stir bars reported a 35% decrease in downtime related to equipment maintenance and a 20% rise in user satisfaction, underlining their practical advantages.

Tips: When selecting PTFE stir bars, it’s important to consider the specific viscosity of the solutions being stirred. For heavier solutions, larger stir bars may be necessary to ensure efficient mixing. Additionally, ensure that the stir bars are compatible with the chemical compounds used in your laboratory to maximize longevity. Another tip is to regularly clean the stir bars according to the manufacturer's guidelines to maintain their effectiveness and prolong their lifespan.

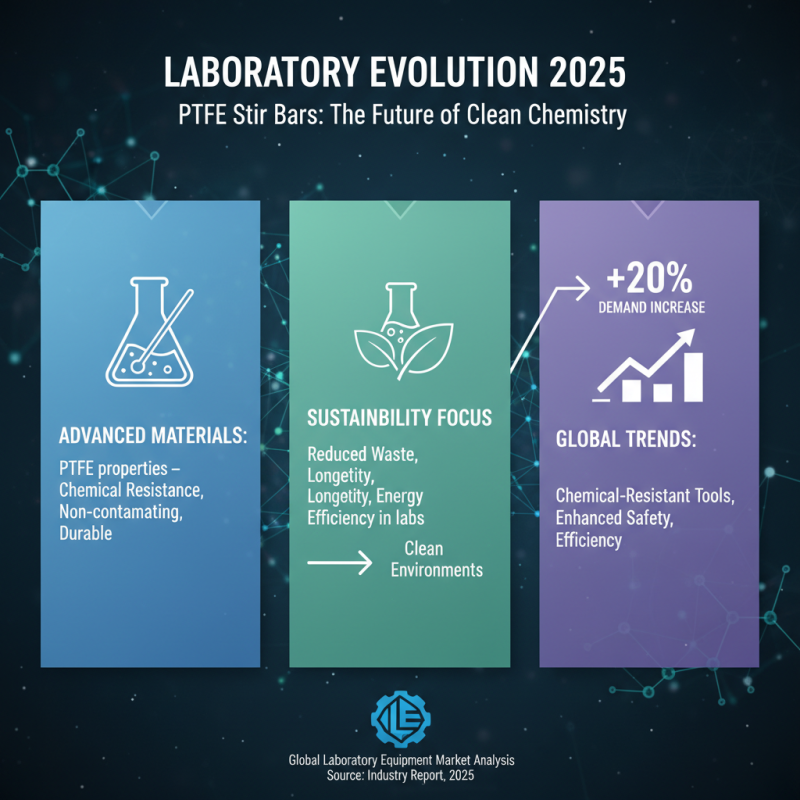

In 2025, the laboratory equipment landscape is predicted to evolve significantly, influenced by advances in materials science and an increasing emphasis on sustainability. PTFE (Polytetrafluoroethylene) stir bars are set to play a pivotal role in this transformation, thanks to their unique properties that enhance laboratory efficiency and safety. According to a report by the Global Laboratory Equipment Market Analysis, the demand for chemical-resistant tools such as PTFE stir bars is expected to rise by 20% as research labs prioritize clean and contamination-free environments.

One of the driving factors behind the popularity of PTFE stir bars is their unparalleled chemical resistance. Unlike traditional stir bars, PTFE does not react with most chemicals, making it ideal for diverse applications. Laboratories utilizing these stir bars report decreased contamination issues, which enhances the reliability of experimental results. Additionally, with the global shift towards eco-friendliness, PTFE’s durability and reusability align perfectly with sustainable laboratory practices, supporting ongoing efforts for greener science.

Tips: When selecting stir bars for your laboratory, consider the specific chemical interactions involved in your experiments. It's recommended to opt for PTFE stir bars for aqueous environments or reactive solvents to ensure optimal performance. Also, keep an eye on emerging trends; attending industry conferences can provide insights into new materials and technologies that may benefit your laboratory processes. By staying informed, you'll ensure that your lab remains at the forefront of innovation.