In the realm of laboratory science, efficiency and precision are paramount, and one of the key tools that enhance these qualities is the Ptfe Magnetic Stir Bars. These innovative stirring devices are engineered from polytetrafluoroethylene (PTFE), a material known for its excellent chemical resistance and stability under varying temperatures. As laboratories increasingly seek to optimize their workflows, understanding the science behind Ptfe Magnetic Stir Bars becomes essential. This article will delve into the mechanics of how these stir bars operate, their advantages over traditional stirring methods, and the optimal practices for their use. By exploring these elements, we aim to empower lab professionals with the knowledge needed to maximize their operational efficiency and achieve consistent, reliable results in their experiments. Join us as we uncover the pivotal role of Ptfe Magnetic Stir Bars in advancing laboratory processes.

PTFE (polytetrafluoroethylene) magnetic stir bars are essential tools in laboratory settings, designed to enhance mixing efficiency and ensure consistent results. The composition of PTFE is notable for its robust chemical resistance, allowing it to remain inert in the presence of a wide array of solvents and aggressive chemicals. This property makes PTFE magnetic stir bars particularly valuable in applications ranging from chemical analysis to biological experiments, where cross-contamination and degradation of materials can significantly disrupt processes.

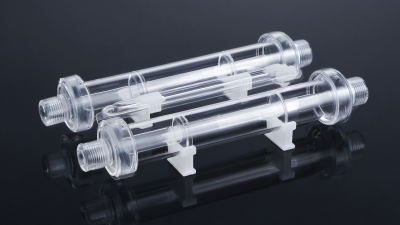

Functionally, these stir bars utilize a magnetic core encased in PTFE, which not only protects the core from potential chemical interaction but also provides a smooth surface for efficient stirring. When placed in a liquid medium, rotating magnets create a vortex that facilitates thorough mixing, ensuring homogeneous solutions. Their non-stick nature ensures that active ingredients are not left adhering to the surface, improving sample recovery and overall reproducibility. With their ability to withstand extreme temperatures and hostile environments, PTFE magnetic stir bars are a cornerstone of optimal laboratory efficiency, supporting a wide range of scientific inquiries.

Magnetic stirring is an essential technique in laboratories, significantly enhancing the efficiency and effectiveness of various experiments. According to a report from Research and Markets, the global market for magnetic stirrers is expected to grow at a CAGR of 6.2% through 2025, driven by their ability to provide consistent and uniform mixing of solutions. This uniformity is crucial in chemical reactions, where even slight discrepancies in concentration can lead to variable results.

Moreover, advancements in magnetic stir bar technology, particularly the use of materials like PTFE, have dramatically improved their performance. PTFE stir bars resist chemical attack and mechanical wear, enabling their use in a wide range of applications, including biological and pharmaceutical research. A study published in the Journal of Laboratory Automation found that the use of high-quality magnetic stir bars could reduce mix time by up to 30%, thereby increasing throughput in busy labs. This efficiency not only saves time but also minimizes errors, as homogeneous mixtures lead to more reliable experimental outcomes.

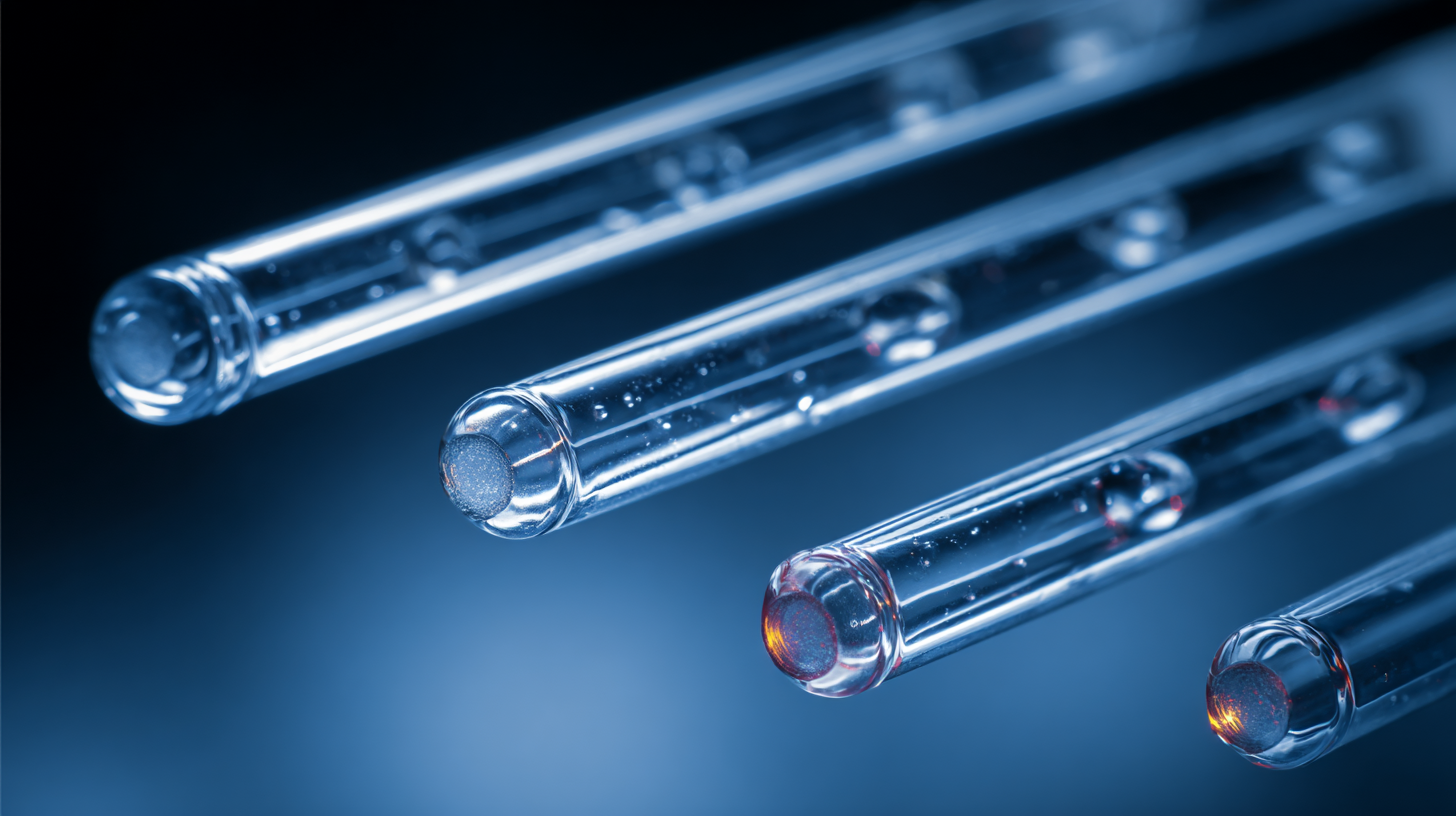

The use of PTFE (polytetrafluoroethylene) coating in magnetic stir bars offers significant advantages in laboratory settings, particularly in applications requiring precision and cleanliness. PTFE's non-stick and chemically resistant properties make these stir bars ideal for extracting contaminants from complex matrices like water. For instance, in techniques such as Stir Bar Sorptive Extraction (SBSE), the PTFE coating ensures that minimal sample residue adheres to the stir bar, facilitating accurate quantitative analysis of contaminants even in the presence of particulate matter.

Furthermore, the application of PTFE-coated magnetic stir bars in solventless microextraction techniques presents a greener alternative for pharmaceutical analysis. These techniques benefit from PTFE’s inert nature, allowing researchers to perform extractions without the risks associated with traditional solvents.

As a result, the integration of PTFE coatings in magnetic stir bars not only enhances lab efficiency but also contributes to stricter environmental standards by minimizing solvent use. Overall, the advantages of PTFE coatings significantly improve the reliability and safety of laboratory practices.

The performance of PTFE magnetic stir bars in laboratory experiments can be significantly influenced by several factors. One primary aspect is the design and size of the stir bar, which directly affects the efficiency of mixing and heat distribution within the sample. Research indicates that optimizing the length and shape of these stir bars can enhance the energy transfer during stirring, leading to more uniform reactions and improved experimental outcomes.

Moreover, the chemical compatibility of PTFE with various solvents is crucial. PTFE is renowned for its excellent chemical resistance, but the specific nature of the solvent can affect the stir bar's performance and longevity. According to a market report, the demand for precise sample preparation systems in pharmaceutical and biotechnology sectors is driving innovations in stir bar technology. With the market projected to grow significantly by 2032, the integration of advanced automation systems is also enhancing stir bar effectiveness, ensuring high-quality results in experiments while maintaining rigorous standards of laboratory safety and efficiency.

When utilizing PTFE (Polytetrafluoroethylene) magnetic stir bars in laboratory settings, it's essential to adhere to best practices to ensure optimal efficiency and experiment integrity.

Firstly, proper selection of stir bar size and shape is crucial for achieving the desired stirring speed and vortex formation. It's recommended to choose a stir bar that is appropriately sized for the volume of liquid being stirred; smaller volumes require smaller stir bars, while larger volumes benefit from longer or more robust options. Additionally, avoid overloading the stir plate, as excessive weight can lead to suboptimal stirring performance and possible equipment damage.

Cleaning and maintaining PTFE stir bars is another critical best practice. PTFE's non-stick properties make it easier to clean, but residual materials can still adhere. Rinse stir bars thoroughly with solvent appropriate for the substances previously stirred, followed by distilled water to remove any remaining contaminants.

Regular inspection for wear and tear is also advisable;

if a stir bar shows signs of damage, such as cracks or chips, it should be replaced to avoid contamination of samples. Implementing these practices not only boosts lab efficiency but also enhances the reliability of experimental results.